Introduction

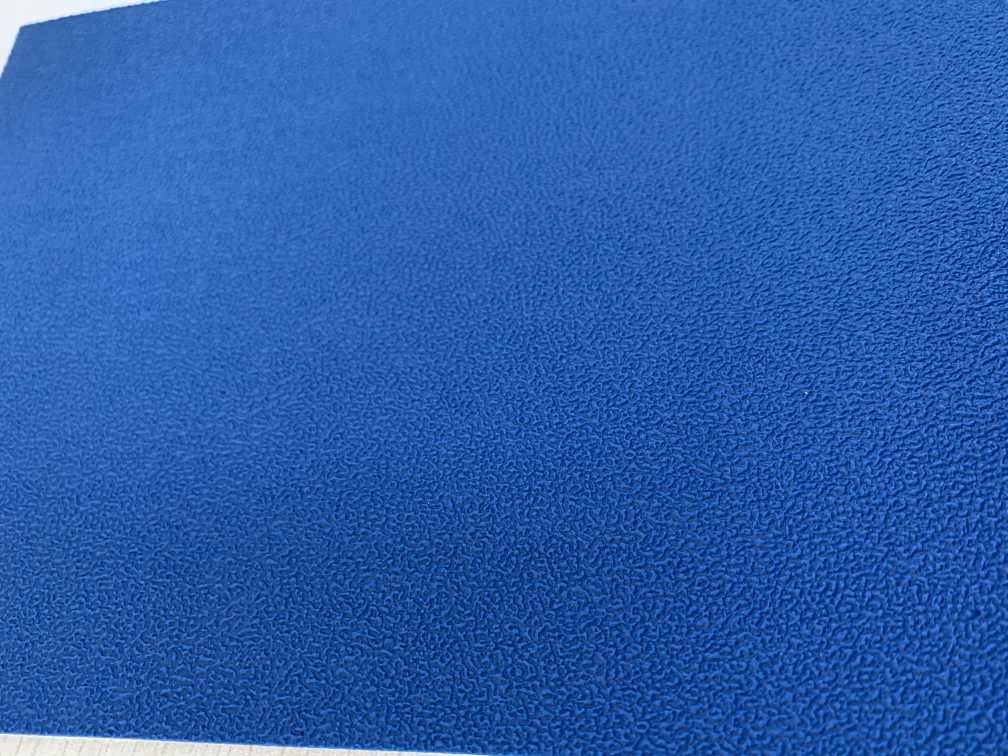

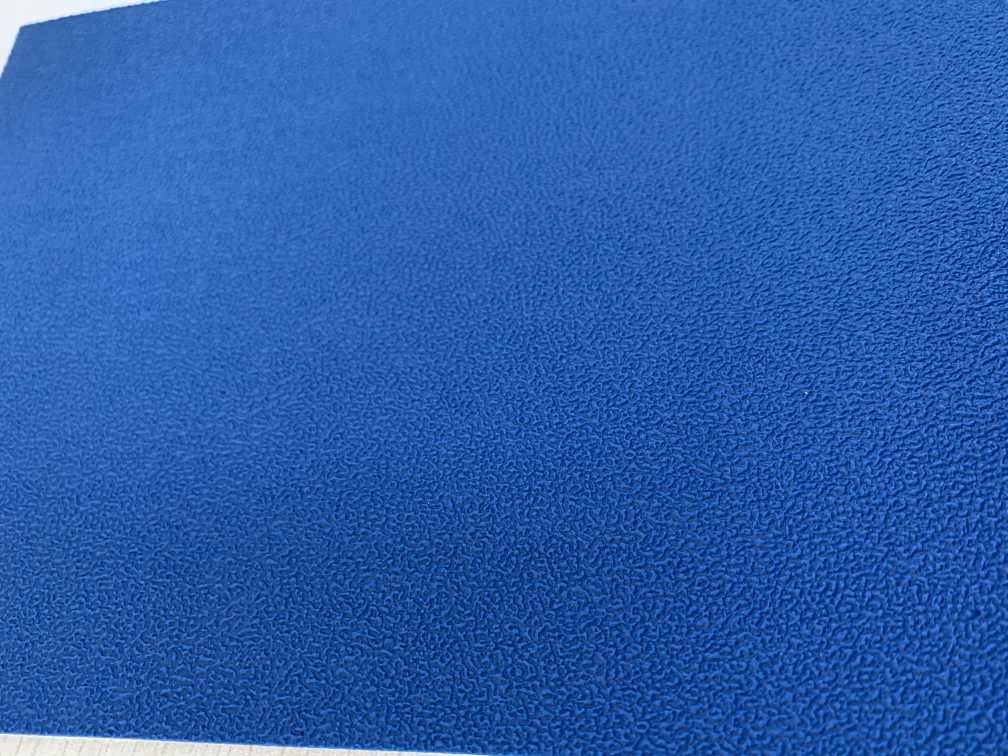

In the bustling world of industrial operations, the conveyor belt serves as a silent workhorse, facilitating the seamless movement of materials and goods with unparalleled efficiency. Among the myriad conveyor belt options available, high-quality PVC solid woven conveyor belts stand out for their durability, versatility, and reliability. However, to ensure these belts continue to perform optimally and maintain their longevity, diligent maintenance practices are essential. In this comprehensive guide, we delve into the key maintenance practices necessary for preserving the integrity and performance of high-quality PVC solid woven conveyor belts.

Regular Cleaning

The first step in maintaining the longevity and optimal performance of high-quality PVC solid woven conveyor belts is regular cleaning. Over time, debris, dirt, and contaminants can accumulate on the belt surface, leading to increased friction, wear, and potential damage. Therefore, it is imperative to implement a regular cleaning regimen to remove these impurities and maintain the cleanliness of the belt. Depending on the operating environment and the level of contamination, cleaning frequency may vary, but it is generally recommended to clean the belt surface thoroughly at regular intervals using appropriate cleaning agents and methods.

Inspection and Monitoring

Regular inspections are indispensable for identifying wear, damage, or abnormalities in high-quality PVC solid woven conveyor belts. By conducting routine inspections, maintenance personnel can detect potential issues early on and take proactive measures to address them before they escalate into more significant problems. Key components to inspect include the belt surface, edges, and splices. Additionally, the utilization of technology, such as sensors and monitoring systems, can provide real-time data on belt performance and condition, enabling predictive maintenance strategies to be implemented effectively.

Proper Tensioning

Maintaining proper belt tension is crucial for ensuring the optimal performance and longevity of high-quality PVC solid woven conveyor belts. Incorrect tensioning can lead to slippage, premature wear, and even belt failure. Therefore, it is essential to measure and adjust belt tension regularly using appropriate methods and equipment. Under-tensioning can result in excessive sagging and increased risk of damage, while over-tensioning can cause undue stress on the belt and associated components. Finding the right balance is key to maximizing belt lifespan and performance.

Lubrication and Conditioning

Proper lubrication of moving parts is essential for reducing friction and wear in high-quality PVC solid woven conveyor belts. Lubricants help to maintain smooth operation and prevent premature degradation of belt components. When selecting lubricants, it is important to choose products that are compatible with PVC materials and suitable for the operating conditions of the conveyor system. In addition to lubrication, conditioning practices can help to preserve the flexibility of PVC belts and prevent cracking, particularly in environments with extreme temperatures or exposure to harsh chemicals.

Splice Maintenance

Belt splices play a critical role in the performance and longevity of high-quality PVC solid woven conveyor belts. Proper maintenance of splices is essential for preventing belt separation, reducing downtime, and ensuring safe operation. Regular inspections should be conducted to identify any signs of wear or damage, and prompt repairs should be carried out using high-quality splice materials and techniques. By maintaining strong and reliable splices, the integrity of the conveyor belt system can be preserved, contributing to overall operational efficiency and productivity.

Environmental Considerations

The operating environment has a significant impact on the maintenance requirements of high-quality PVC solid woven conveyor belts. Extreme temperatures, moisture, and exposure to chemicals can accelerate wear and deterioration, necessitating additional protective measures. Strategies such as implementing protective covers, sealing conveyor systems, and using corrosion-resistant materials can help to mitigate environmental damage and prolong the lifespan of conveyor belts. Additionally, preventive maintenance practices, such as regular inspections and cleaning, are essential for identifying and addressing environmental hazards before they cause significant damage.

Training and Education

Effective maintenance of high-quality PVC solid woven conveyor belts requires knowledgeable and skilled personnel. Providing comprehensive training and education for maintenance staff is essential for ensuring that they have the necessary skills and expertise to perform maintenance tasks safely and effectively. Training programs should cover proper maintenance techniques, safety protocols, and equipment operation. By investing in employee training and education, businesses can foster a culture of proactive maintenance and continuous improvement, leading to better operational outcomes and increased productivity.

Documentation and Record-Keeping

Maintaining accurate records of maintenance activities and inspections is essential for tracking the performance and condition of high-quality PVC solid woven conveyor belts over time. Documentation should include details such as maintenance dates, tasks performed, and any observations or findings. By keeping thorough records, maintenance personnel can identify trends, track changes in belt condition, and make informed decisions regarding maintenance schedules and priorities. Additionally, historical data can be invaluable for troubleshooting issues and optimizing maintenance strategies to maximize belt lifespan and performance.

Conclusion

In conclusion, the longevity and optimal performance of high-quality PVC solid woven conveyor belts depend on diligent maintenance practices and proactive management. By implementing a comprehensive maintenance program that includes regular cleaning, inspections, proper tensioning, lubrication, splice maintenance, environmental protection, training, and documentation, businesses can maximize the lifespan of their conveyor belts and ensure reliable operation. Investing in maintenance not only preserves the integrity of conveyor belt systems but also enhances operational efficiency, reduces downtime, and ultimately contributes to the bottom line. With proper care and attention, high-quality PVC solid woven conveyor belts can continue to deliver reliable performance and support the success of industrial operations for years to come.