Introduction

In the dynamic landscape of material handling, the performance and durability of conveyor belts play a pivotal role in ensuring operational efficiency. Leading PVC conveyor belt manufacturers are at the forefront of driving advancements through innovative features and cutting-edge technologies. In this comprehensive exploration, we delve into the world of PVC conveyor belts, uncovering the latest innovations that enhance performance and durability, ultimately reshaping the industry.

Advanced Material Selection

At the core of PVC conveyor belt innovation lies the selection of advanced materials. We’ll examine how PVC conveyor belt manufacturers leverage state-of-the-art materials to enhance the overall performance and durability of conveyor belts. From wear-resistant compounds to materials designed for specific industrial applications, understanding the role of advanced materials is key to grasping the evolution of PVC conveyor belt technology.

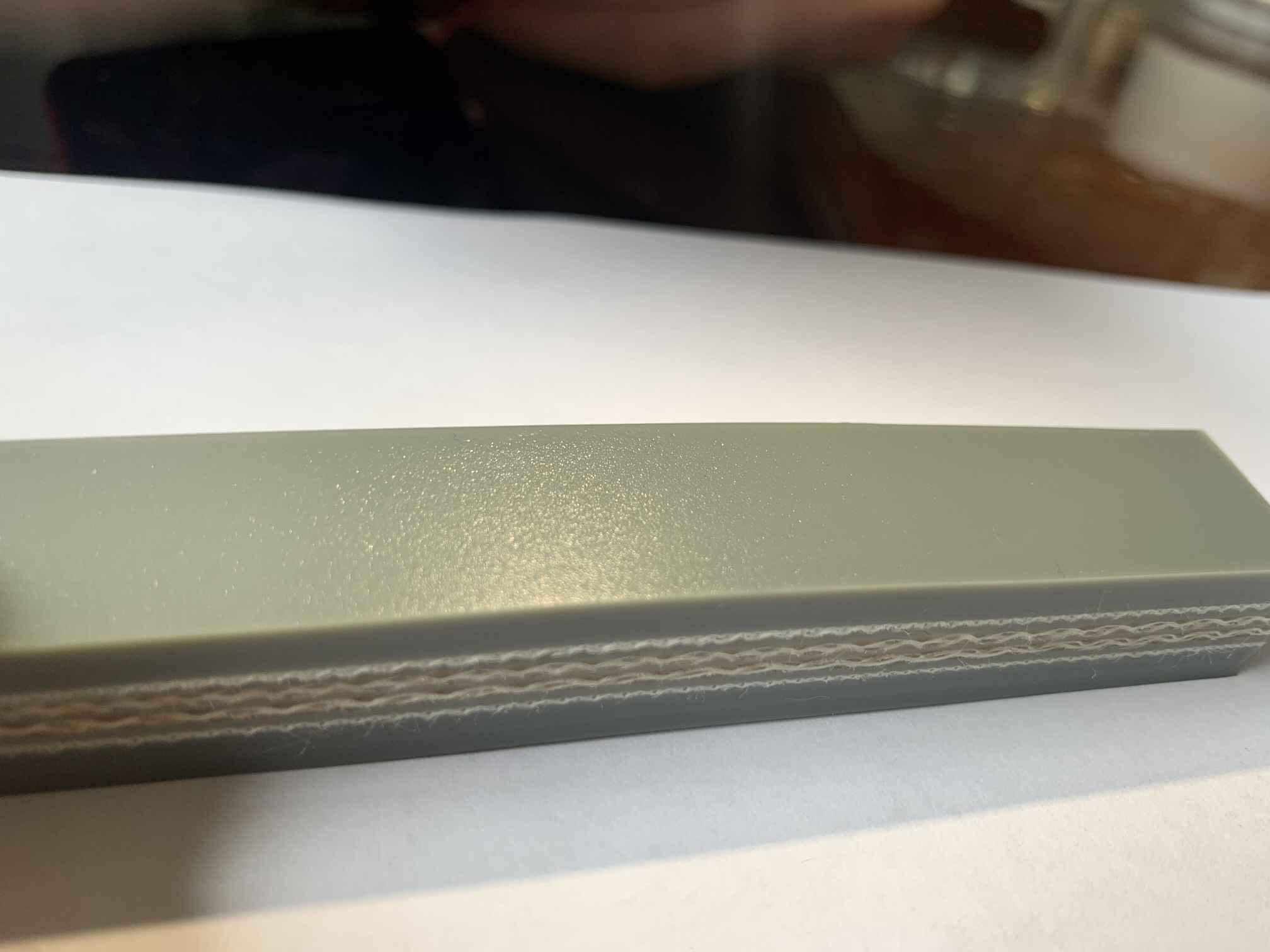

Reinforcement Technologies

The strength and load-bearing capacity of PVC conveyor belts are significantly influenced by reinforcement technologies. This section provides an overview of various reinforcement methods, including fabric and steel cord, and explores how these technologies contribute to the robustness and longevity of conveyor belts. Understanding the nuances of reinforcement is crucial for those seeking belts capable of withstanding demanding material handling tasks.

Coating and Surface Technologies

Innovative coatings and surface technologies are instrumental in enhancing the resistance of PVC conveyor belts to abrasion, chemicals, and other environmental factors. We’ll delve into the latest advancements in coating technologies, examining how they not only protect the belt but also contribute to smoother operation through reduced friction and improved grip. This exploration sheds light on the role of surface innovations in extending belt life and minimizing maintenance needs.

Tracking and Alignment Systems

Maintaining proper alignment and tracking is critical for the longevity and efficiency of conveyor belts. Advanced tracking systems have emerged as a key innovation in this regard. This section explores the functionalities of these systems and their impact on preventing misalignment issues, ultimately contributing to prolonged belt life and reduced downtime.

Smart Sensors and Monitoring

The integration of smart sensors and monitoring systems has revolutionized the way conveyor belts are maintained. Real-time data on belt conditions allows for predictive maintenance, reducing the risk of unexpected breakdowns and enhancing overall durability. We’ll discuss the role of sensors in monitoring factors such as tension, temperature, and wear, providing insights into how these technologies optimize conveyor belt performance.

Modular Design and Customization

Innovative conveyor belt manufacturers are embracing modular design principles, offering benefits such as easy installation, replacement, and customization. This section explores the advantages of modular design and how customization options cater to specific industry needs. Understanding these features enables businesses to adapt conveyor belts to their unique requirements, ultimately improving efficiency.

Energy-Efficient Technologies

Energy efficiency has become a focal point in conveyor belt innovation. We’ll explore technologies designed to minimize energy consumption, contributing to both sustainability and cost savings. From optimized drive systems to regenerative braking, these innovations showcase how conveyor belts are evolving to meet the growing demand for environmentally conscious solutions.

Anti-static and Flame-Resistant Features

Static buildup and fire safety concerns are significant considerations in certain industries. We’ll delve into the importance of anti-static properties in preventing static electricity-related issues and explore flame-resistant technologies designed to enhance safety in applications where fire hazards are a concern. Understanding these features is crucial for industries with specific regulatory and safety requirements.

Case Studies

Real-world examples serve as tangible proof of the impact of innovative features on PVC conveyor belt performance. Through case studies, we’ll showcase instances where leadingPVC conveyor belt manufacturershave successfully implemented advanced technologies, resulting in tangible improvements in efficiency, reliability, and durability. These practical examples provide valuable insights for businesses seeking evidence of the real-world benefits of adopting innovative conveyor belt solutions.

Industry Impact and Market Trends

The influence of innovative features on industry standards is undeniable. This section examines how advancements in PVC conveyor belt technologies are shaping industry norms and influencing market trends. Whether it’s the adoption of specific features as benchmarks or the emergence of new requirements driven by technological innovations, understanding the industry impact is crucial for staying ahead in the competitive landscape.

Challenges and Future Developments

While innovation brings numerous benefits, it also poses challenges in terms of implementation and adoption. We’ll discuss potential challenges faced byPVC conveyor belt manufacturersand end-users in integrating advanced features into their conveyor belt systems. Additionally, we’ll explore predictions for future developments in PVC conveyor belt technologies, offering a glimpse into the evolving landscape of material handling solutions.

Conclusion

In conclusion, the world of PVC conveyor belts is undergoing a transformative phase, driven by innovative features and technologies. From advanced material selection to smart sensors, each aspect contributes to enhanced performance, durability, and efficiency. Leading PVC conveyor belt manufacturers play a pivotal role in shaping the future of conveyor belt technology, influencing industry standards and market trends. As businesses navigate the evolving landscape of material handling, understanding and embracing these innovations is key to unlocking the full potential of PVC conveyor belts and driving efficiency in diverse industrial applications.