Introduction

When it comes to the efficiency and reliability of your industrial processes, the conveyor belt plays a pivotal role. Whether you operate in heavy-duty industries like mining and construction, the meticulous world of food processing, or the precision-driven automotive and manufacturing sectors, selecting the right conveyor belt is paramount. In this comprehensive guide, we will explore the factors you should consider when choosing a PVC (Polyvinyl Chloride) or PU (Polyurethane) conveyor belt supplier tailored to your specific industry or application needs.

Industry and Application Analysis

Understanding Your Specific Industry Requirements

The first step in selecting the right PVC or PU conveyor belt supplier is gaining a deep understanding of your industry’s unique requirements. Each industry has its own set of demands that the conveyor belt must meet.

- Heavy-Duty Industries

In industries like mining and construction, conveyor belts are subjected to extreme conditions. These belts need to withstand heavy loads, abrasive materials, and harsh environments. Durability, strength, and resistance to wear and tear are crucial considerations.

- Food Processing and Hygiene-Sensitive Applications

Food processing and pharmaceutical industries have stringent hygiene and safety standards. Conveyor belts used here must be easy to clean and resistant to chemicals. Compliance with food safety regulations is non-negotiable.

- Automotive and Manufacturing

Precision, speed, and reliability are essential in automotive and manufacturing applications. Conveyor belts need to be highly customizable to accommodate various product sizes and shapes. They should also minimize downtime and facilitate efficient production.

Identifying Unique Application Needs

Beyond industry-specific requirements, your specific application will have its own unique demands on the conveyor belt. Consider the following factors:

- Temperature and Environmental Considerations

Is your application exposed to extreme temperatures, either high or low? PVC and PU conveyor belts have different temperature resistance capabilities, so choosing the right material is crucial.

- Conveyor Belt Size and Design Specifications

The size and design of the conveyor belt should align with the layout and requirements of your production line. Customization might be necessary to ensure optimal performance.

- Material Compatibility

Ensure that the conveyor belt material is compatible with the products or materials it will be transporting. Chemical resistance is particularly important when dealing with corrosive substances.

Material Selection

PVC vs. PU Conveyor Belts

The choice between PVC and PU conveyor belts is one of the most critical decisions you’ll make. Each material has its own set of properties, advantages, and disadvantages.

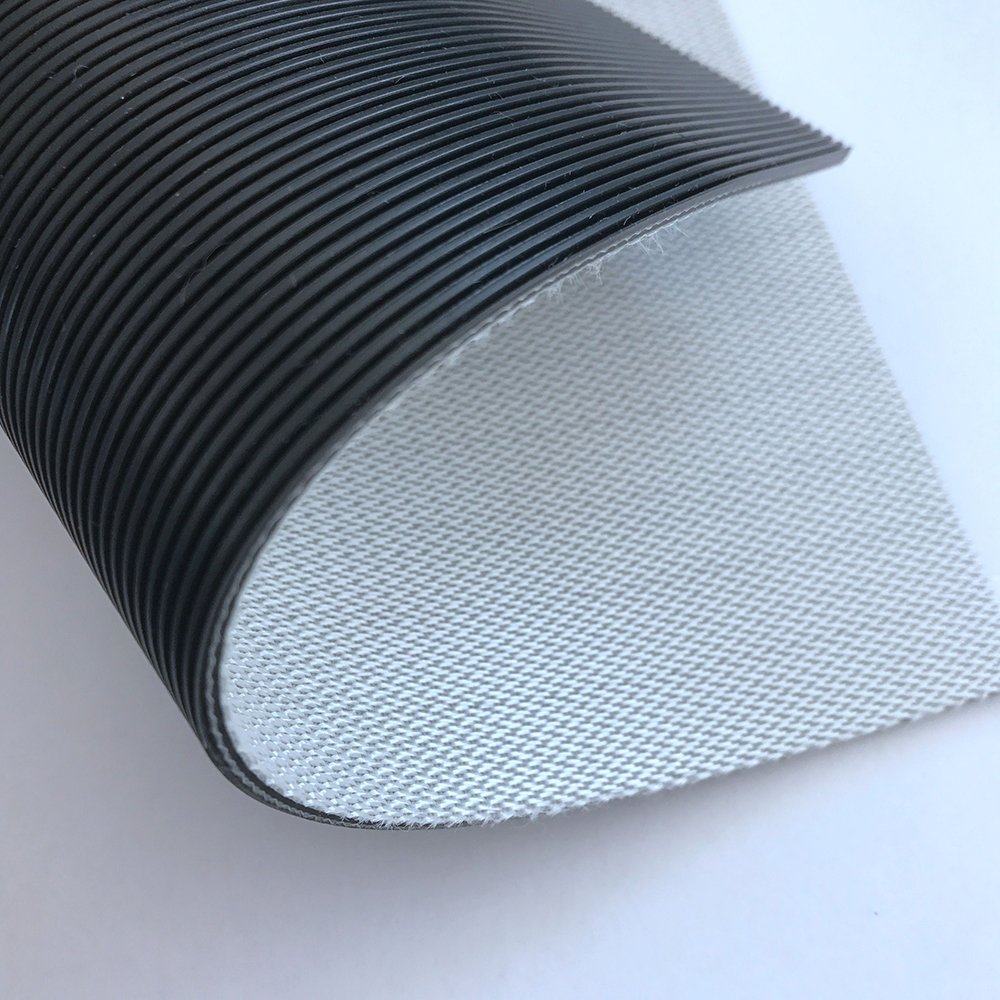

- Properties and Characteristics

PVC Conveyor Belts: PVC belts are known for their durability and resistance to abrasion. They are also highly flexible and cost-effective.

PU Conveyor Belts: PU belts are characterized by their excellent wear resistance, flexibility, and resistance to oil and grease.

- Advantages and Disadvantages

PVC Conveyor Belts:

Advantages: Durability, affordability, and suitability for heavy-duty applications.

Disadvantages: Limited temperature resistance, may not be suitable for some food processing applications.

PU Conveyor Belts:

Advantages: Excellent wear resistance, flexibility, and compatibility with food-grade applications.

Disadvantages: Slightly higher initial cost, may not be as durable in extremely abrasive environments.

- Matching Material Properties to Industry/Application Requirements

Select the material that best aligns with your industry and application requirements. For instance:

For heavy-duty industries, PVC belts might be preferable due to their durability.

Food processing industries may opt for PU belts due to their hygiene-friendly properties.

PVC or PU conveyor belt supplier Evaluation

Once you have a clear understanding of your industry and application needs, it’s time to evaluate potential conveyor belt suppliers.

Assessing PVC or PU conveyor belt supplier Reputation and Experience

- Industry Experience and Track Record

Look for PVC or PU conveyor belt suppliers with a proven track record in your specific industry. Experience often translates to a deeper understanding of industry requirements.

- Customer Testimonials and Reviews

Reading reviews and testimonials from other customers can provide insights into the PVC or PU conveyor belt supplier’s reliability and the quality of their products and services.

Quality and Manufacturing Standards

- Production Processes and Technologies

Inquire about the PVC or PU conveyor belt supplier’s manufacturing processes and technologies. Advanced production methods can lead to higher-quality conveyor belts.

- Compliance with Industry Standards

Ensure that the PVC or PU conveyor belt supplier complies with relevant industry standards and regulations. This is especially crucial in food processing and pharmaceutical industries.

Customization Capabilities

- Tailoring Conveyor Belts to Specific Needs

Check if the PVC or PU conveyor belt supplier offers customization options to meet your unique conveyor belt requirements. This might include size, design, and material adjustments.

- Prototyping and Design Support

Some PVC or PU conveyor belt suppliers provide prototyping and design support services, which can be invaluable when creating custom conveyor belts.

Pricing and Cost Analysis

While cost is a significant factor, it should not be the sole determinant in your decision-making process.

Comparing Pricing Structures

- Initial Purchase Cost

Consider the initial purchase cost of the conveyor belts. PVC belts are generally more affordable upfront, but total cost of ownership should be assessed.

- Total Cost of Ownership

Look beyond the initial cost and assess the long-term expenses, including maintenance, repairs, and replacement.

Evaluating Value-Added Services

- Warranty and After-Sales Support

Inquire about the PVC or PU conveyor belt supplier’s warranty policies and after-sales support. A robust support system can minimize downtime and reduce overall costs.

- Maintenance and Repair Services

Some PVC or PU conveyor belt suppliers offer maintenance and repair services, which can be convenient and cost-effective over the lifespan of the conveyor belts.

Lead Times and Supply Chain Considerations

Assessing Lead Times for Conveyor Belt Production

Determine the lead times for conveyor belt production. Delays can impact your operations, so understanding production timelines is crucial.

Supply Chain Reliability

- Consistency in Product Availability

Assess the PVC or PU conveyor belt supplier’s ability to consistently provide the conveyor belts you need, especially during peak demand periods.

- Emergency Order Capabilities

Inquire about the PVC or PU conveyor belt supplier’s emergency order capabilities. Can they accommodate urgent requests when downtime is not an option?

Sustainability and Environmental Factors

In today’s environmentally conscious world, sustainability is a critical consideration.

Evaluating the Environmental Impact

- Recyclability and Waste Reduction

Check if the conveyor belt materials are recyclable, and whether the PVC or PU conveyor belt supplier promotes waste reduction practices.

- Energy-Efficient Production Processes

Inquire about the PVC or PU conveyor belt supplier’s production processes. Energy-efficient methods contribute to reduced environmental impact.

PVC or PU conveyor belt supplier Commitment to Sustainability

- Use of Eco-Friendly Materials

Determine if the PVC or PU conveyor belt supplier uses eco-friendly materials in their conveyor belts. Sustainable materials contribute to a greener supply chain.

- Green Certifications and Initiatives

Look for PVC or PU conveyor belt suppliers that have obtained green certifications or actively participate in sustainability initiatives.

Conclusion

In conclusion, choosing the right PVC or PU conveyor belt supplier for your specific industry or application is a multifaceted process. By understanding your industry and application requirements, carefully evaluating potential PVC or PU conveyor belt suppliers, and considering factors such as material selection, pricing, lead times, and sustainability, you can make an informed decision that will contribute to the efficiency and success of your operations. Remember, a well-chosen conveyor belt PVC or PU conveyor belt supplier can be a valuable partner in your business journey, ensuring smooth and reliable material handling for years to come.