Introduction

In the world of material handling and industrial processes, the choice of conveyor belts is a critical decision that directly impacts efficiency and performance. When it comes to solid woven conveyor belts, selecting a reliable solid woven conveyor belts manufactureris paramount to ensuring that the belts meet specific industrial needs. This article explores the key factors that should be considered when choosing a manufacturer for solid woven conveyor belts tailored to individual industrial requirements.

Industry-specific Requirements

Understanding the unique needs of different industries is the first step in selecting the right conveyor belts manufacturer. Industries vary in terms of materials being transported, environmental conditions, and operational demands. A reliable solid woven conveyor belts manufacturer should have the expertise to tailor conveyor belt solutions that address these specific requirements, providing optimal performance in diverse industrial settings.

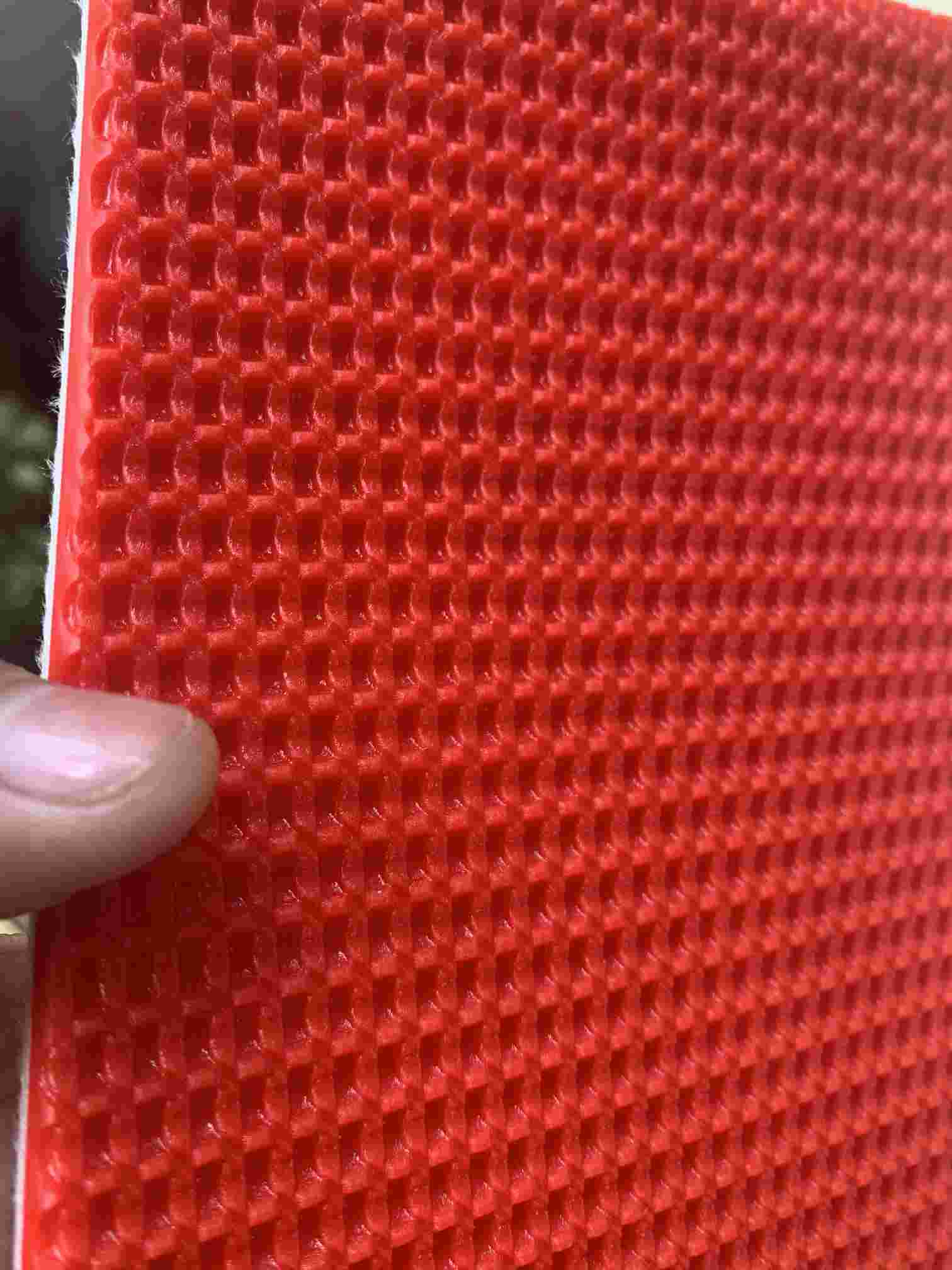

Material Quality and Composition

The quality of materials used in manufacturing solid woven conveyor belts is a critical factor influencing their performance and longevity. High-quality materials contribute to the durability and resilience of the belts. Evaluating the composition and characteristics of the materials used by a manufacturer is essential in ensuring that the conveyor belts meet the standards required for robust and reliable performance.

Manufacturing Process

An overview of the manufacturing process employed by a conveyor belts manufacturer provides insights into the technology, equipment, and quality control measures in place. A reliable manufacturer utilizes advanced manufacturing processes to produce conveyor belts with consistent quality. Understanding the manufacturing process helps in assessing the precision and efficiency of belt production.

Customization Capabilities

The ability to customize solid woven conveyor belts according to unique specifications is crucial for meeting individual industrial needs. A reliable solid woven conveyor belts manufacturer should offer a range of customization options, including belt dimensions, materials, and additional features. Customization ensures that the conveyor belts align perfectly with the requirements of specific applications, enhancing their effectiveness.

Durability and Longevity

The durability of solid woven conveyor belts is a key consideration, especially in industries with demanding working environments. Factors influencing durability include the quality of materials, design, and manufacturing processes. Assessing the expected lifespan of the belts in specific conditions helps in selecting a manufacturer that prioritizes longevity and minimizes the need for frequent replacements.

Compliance with Industry Standards

Adherence to safety and quality standards is non-negotiable when choosing a solid woven conveyor belts manufacturer. Regulatory compliance ensures that the belts meet industry standards for performance and safety. Verifying the manufacturer’s certifications and adherence to relevant regulations provides assurance of the quality and reliability of their conveyor belts.

Reputation and Track Record

A manufacturer’s reputation in the industry speaks volumes about the reliability of their products. Positive reviews, testimonials, and a strong track record indicate a manufacturer’s commitment to delivering quality conveyor belts. Researching the reputation of potential manufacturers helps in selecting a partner with a proven history of customer satisfaction and reliable products.

Support and Service

The availability of customer support and after-sales services is essential for a long-term partnership with a conveyor belts manufacturer. A reliable solid woven conveyor belts manufacturer should offer comprehensive support, including assistance with installation, maintenance, and troubleshooting. Evaluating the manufacturer’s commitment to ongoing support ensures a smooth experience throughout the lifespan of the conveyor belts.

Cost Considerations

While quality is a priority, cost considerations are also crucial when selecting a manufacturer. Balancing quality and cost-effectiveness ensures that the chosen conveyor belts provide value for the investment. Assessing the overall value offered by the manufacturer in relation to pricing helps in making an informed decision that aligns with budgetary constraints.

Environmental Considerations

Environmental sustainability is an increasingly important factor in industrial decision-making. Evaluating a manufacturer’s commitment to eco-friendly practices, including the use of sustainable materials and environmentally conscious manufacturing processes, aligns with the broader goals of reducing the ecological impact of industrial operations.

Case Studies

Examining case studies of successful partnerships with solid woven conveyor belts manufacturers provides real-world examples of effective solutions for specific industrial needs. Learning from these experiences helps in understanding how manufacturers have addressed unique challenges and tailored solutions to meet the diverse requirements of different industries.

Conclusion

In conclusion, selecting a reliable solid woven conveyor belts manufacturer involves a comprehensive assessment of various factors. Understanding industry-specific requirements, evaluating material quality, customization capabilities, and considering factors such as durability, compliance, reputation, support, cost, and environmental considerations are all crucial steps in making an informed decision. By taking these factors into account, businesses can forge strong partnerships with manufacturers that deliver conveyor belts tailored to their specific industrial needs, ensuring optimal performance and efficiency.