In the intricate web of industries and logistics, conveyor belts serve as the silent backbone, diligently ferrying materials and products across various sectors. These unsung heroes are essential to optimizing workflow, enhancing productivity, and ensuring seamless operations. However, in the quest for cost efficiency without compromising quality, it’s crucial to unravel the factors that influence the pricing of low PU (Polyurethane) conveyor belts. This article delves deep into the world of conveyor belts, particularly focusing on low PU variants, to explore the determinants of their pricing and strategies that empower businesses to secure cost-effective options while maintaining quality.

The Pivotal Role of Low PU Conveyor Belts

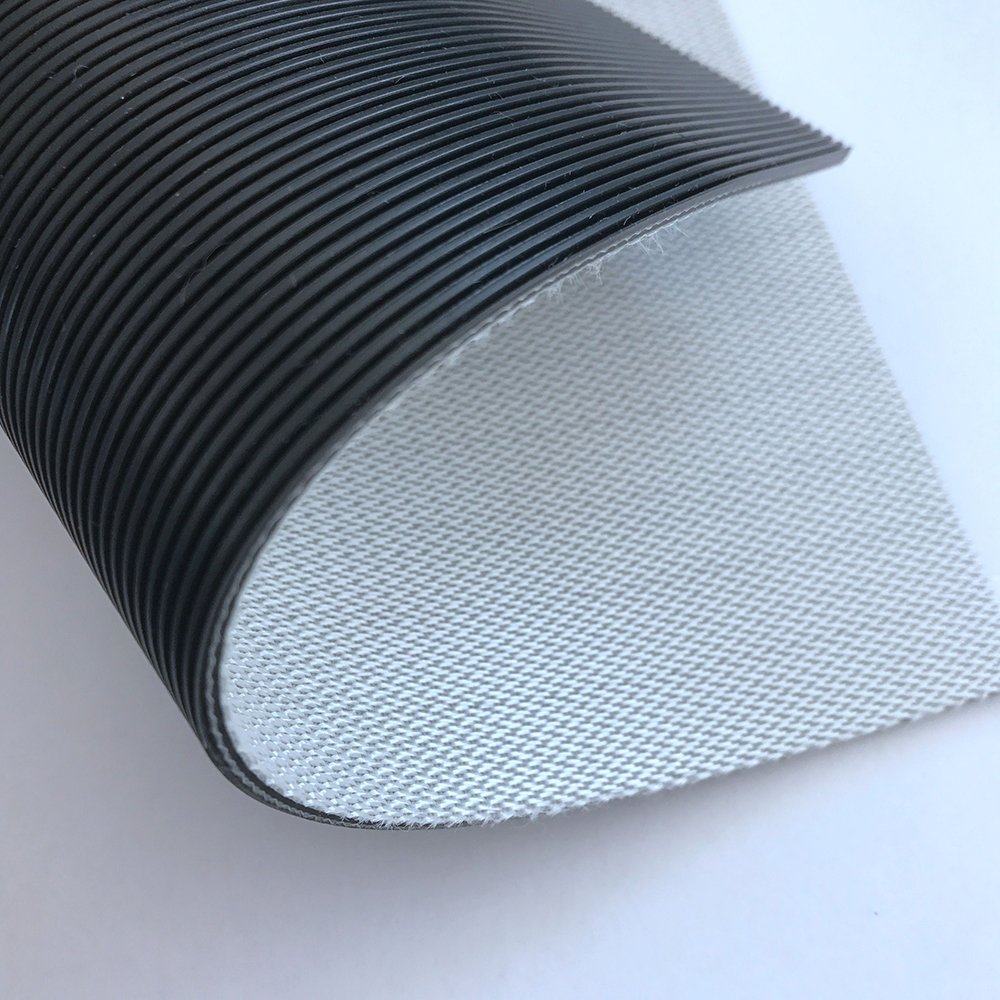

Before dissecting the factors affecting pricing, let’s underscore the significance of low PU conveyor belts. These belts, crafted from polyurethane, offer a compelling fusion of affordability and performance. Widely used across industries, they are celebrated for their adaptability, durability, and applicability across a spectrum of scenarios.

Deciphering the low pu conveyor belt price Equation: Factors at Play

- Material Composition: Unveiling the PU Secret

The foundation of any conveyor belt lies in its material composition. Polyurethane takes center stage, but not all PU is created equal.

PU Hardness: The hardness rating of PU conveyor belts varies. Low PU belts, characterized by a lower hardness rating, offer greater flexibility. While they might not match the rigidity of high-hardness counterparts, they excel in applications where flexibility and cost-efficiency are paramount.

- Customization and Dimensions: Size Matters

Size and length wield significant influence over the low pu conveyor belt price of a conveyor belt. Manufacturers offer standard sizes, but customization is often imperative to meet unique industrial needs.

Standard vs. Custom Sizing: Standard-sized belts are readily available and generally cost less than customized counterparts. However, industries with specialized requirements often necessitate custom sizing to align with existing systems or fulfill precise mandates. While customization might incur added expenses, it guarantees a perfect fit for the task at hand.

- Belt Thickness: Balancing Durability

Belt thickness plays a pivotal role in a conveyor belt’s durability and performance.

Thicker Belts for Endurance: Thicker belts are renowned for their durability and prolonged lifespan. They can withstand heavier loads and endure more demanding conditions. While thicker belts may command a higher initial cost, they prove cost-effective over time by reducing replacement and maintenance expenses.

- The Role of Reinforcements: Strengthening the Core

Conveyor belts often incorporate reinforcements, such as fabric or steel cords, to bolster their strength and load-bearing capacity.

Reinforcement Variety: The choice of reinforcement significantly impacts conveyor belt pricing. Belts reinforced with steel cords, known for their robustness, typically come at a higher low pu conveyor belt price point due to their added strength.

- Surface Finish and Coatings: The Outer Sheen

The surface finish and coatings of a conveyor belt can significantly impact its performance and cost.

Specialized Coatings: Conveyor belts may feature specialized coatings or finishes to enhance characteristics like grip, abrasion resistance, or resistance to chemicals. While these coatings augment overall performance, they contribute to the belt’s price.

Securing Cost-Efficient Excellence: Strategies for Businesses

The quest for cost efficiency need not entail compromising on quality. Balancing the two is an art that businesses can master with strategic approaches.

- Research and Supplier Comparison: The Foundation

Identifying reputable suppliers celebrated for delivering quality low PU conveyor belts at competitive low pu conveyor belt prices is paramount. Factors like their track record, certifications, and customer reviews should guide your selection. By conducting exhaustive research and comparing options, businesses can make informed decisions.

- Bulk Procurement and Negotiation: The Power of Volume

Exploring bulk purchases can yield substantial cost savings. Suppliers often offer discounts on larger orders, making it an attractive proposition for businesses acquiring multiple conveyor belts. Skillful negotiation with suppliers can also yield favorable pricing terms.

- Long-Term Cost Assessment: Beyond the Initial Purchase

When evaluating conveyor belt options, the focus must extend beyond the initial purchase low pu conveyor belt price. Consider the total cost of ownership, encompassing maintenance, repairs, and the expected lifespan of the belt. Investing upfront in a higher-quality belt can result in lower long-term costs by reducing downtime and frequency of replacements.

- Refurbished or Recycled Alternatives: Sustainability Meets Savings

Certified refurbished conveyor belts offer a sustainable and cost-effective alternative. These belts undergo rigorous testing and refurbishment processes to meet industry standards. Businesses with budget constraints can find refurbished options to be both viable and environmentally responsible choices.

- Financing and Leasing Possibilities: Smoothing the Financial Path

For businesses seeking to spread the cost of conveyor belts over time, exploring financing and leasing options is a strategic move. Financing facilitates manageable installment payments, alleviating the immediate financial burden. Leasing provides flexibility by allowing businesses to upgrade or replace equipment as needed.

In Conclusion: Bridging Efficiency and Affordability

In conclusion, low PU conveyor belts represent a cost-effective and versatile solution for a multitude of industries. Achieving the delicate equilibrium between cost efficiency and quality is the key to success. Understanding the factors that influence pricing, assessing customization options, and adhering to strategic procurement practices empower businesses to navigate the conveyor belt market with confidence.

As businesses aspire to elevate operational efficiency and maximize cost savings, it is vital to remember that a conveyor belt is an investment in the uninterrupted flow of materials and products. Ensuring that the chosen conveyor belt aligns with quality standards is fundamental to reducing downtime, optimizing productivity, and ultimately reaping a substantial return on investment.

The journey to discovering cost-effective low PU conveyor belt solutions while safeguarding quality is a path to operational efficiency and financial prudence, benefiting businesses across a myriad of industries.