Introduction

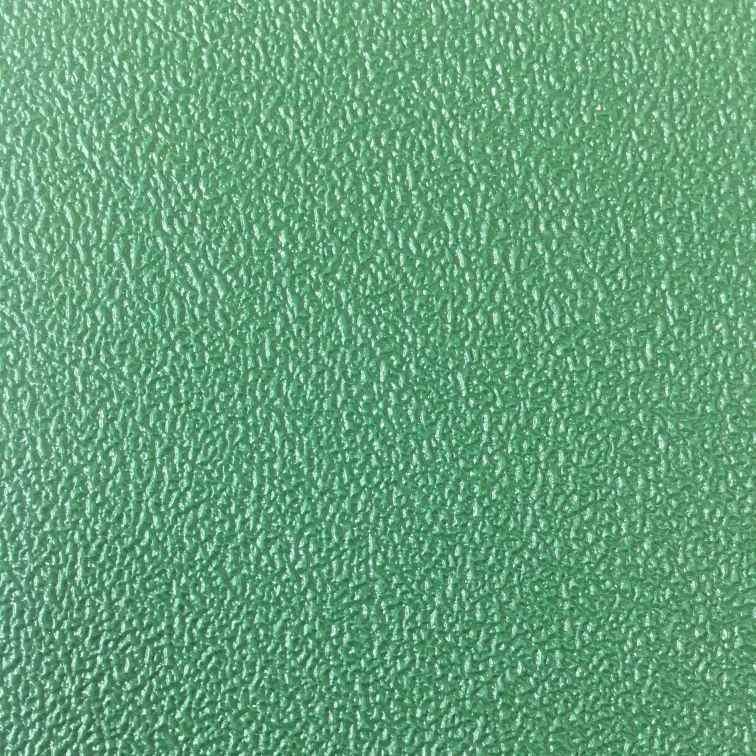

The utilization of PVC conveyor belt materials in industrial applications has been pivotal for streamlining operations, ensuring efficient material handling, and maintaining productivity. However, not all conveyor belt materials are created equal. It’s essential to discern the key differentiators that set high-quality PVC conveyor belt material apart from its standard counterparts.

Characteristics of Standard PVC Conveyor Belt Material

Standard PVC conveyor belt material typically exhibits fundamental features such as flexibility, moderate durability, and resistance to mild abrasion. While adequate for some applications, these materials often possess limitations when subjected to demanding industrial environments.

Key Attributes of High-Quality PVC Conveyor Belt Material

- Superior Durability and Wear Resistance

High-quality PVC conveyor belt material boasts exceptional durability, capable of withstanding heavy loads, continuous use, and harsh operating conditions. The composition of high-quality materials includes reinforced layers that provide robustness, preventing premature wear and tear.

- Enhanced Flexibility and Tensile Strength

Unlike standard materials, high-quality PVC conveyor belt material offers increased flexibility without compromising on tensile strength. This flexibility ensures seamless movement around pulleys and through complex conveyor systems, minimizing strain and potential breakage.

- Chemical Resistance and Industry Suitability

The hallmark of high-quality PVC conveyor belt material lies in its resistance to chemicals, oils, and extreme temperatures. This makes it suitable for diverse industries, including food processing, pharmaceuticals, manufacturing, and logistics, where exposure to varying elements is prevalent.

- Consistency in Thickness and Dimensional Stability

High-quality PVC conveyor belt material maintains a consistent thickness and dimensional stability throughout its structure. This uniformity ensures smooth operation, reducing friction and avoiding misalignment issues commonly encountered with standard materials.

Manufacturing Process and Quality Control

The production of high-quality PVC conveyor belt material involves meticulous manufacturing processes that adhere to stringent quality standards.

- Manufacturing Techniques

These techniques encompass advanced mixing, calendaring, and curing processes. The careful selection and blending of raw materials along with precise manufacturing methods result in materials of superior quality.

- Quality Control Measures

Factories producing high-quality PVC conveyor belt material implement rigorous quality control measures at every stage of production. This includes thorough inspections, material testing for strength and durability, and compliance with internationally recognized standards.

Performance Comparison and Industrial Applications

Contrasting the performance of standard PVC conveyor belt material with its high-quality counterpart reveals stark differences in various industrial applications.

- Industries Benefitting from High-Quality Materials

Industries requiring heavy-duty material handling, such as mining, construction, and automotive, benefit significantly from the robustness and durability of high-quality PVC conveyor belt material. Additionally, industries necessitating strict hygiene standards, like food processing and pharmaceuticals, leverage its chemical resistance and reliability.

- Impact on Efficiency and Maintenance Costs

The utilization of high-quality PVC conveyor belt material contributes to enhanced operational efficiency, reduced downtime, and lower maintenance costs. The superior durability and wear resistance translate into longer lifespan and decreased replacement frequency, resulting in cost savings for businesses.

Case Studies or Testimonials

Several case studies and testimonials highlight the success stories associated with the adoption of high-quality PVC conveyor belt material.

- Case Study A – Automotive Manufacturing

A prominent automotive manufacturing plant reported a significant reduction in maintenance costs and downtime after switching to high-quality PVC conveyor belt material. The material’s resistance to oils and abrasion resulted in uninterrupted production lines, contributing to substantial cost savings.

- Testimonial B – Food Processing Industry

A leading food processing company praised the chemical resistance and cleanliness of high-quality PVC conveyor belt material. The material’s ability to withstand rigorous cleaning procedures while maintaining hygiene standards transformed their production processes, ensuring compliance with stringent regulations.

Conclusion

The distinctive features and superior performance of high-quality PVC conveyor belt material are undeniable. Its durability, flexibility, chemical resistance, and consistency make it an indispensable asset across various industries, revolutionizing material handling and contributing to operational efficiency.

Selecting the appropriate conveyor belt material is crucial for optimizing productivity, minimizing maintenance, and ensuring operational continuity. High-quality PVC conveyor belt material stands as a testament to technological advancements and innovation, promising reliability and longevity in demanding industrial settings.

As industries evolve, so do the materials supporting their operations. The continuous advancements and refinements in high-quality PVC conveyor belt materials indicate a promising future, offering businesses a competitive edge and sustained efficiency in the ever-evolving industrial landscape.