Introduction

In the realm of tobacco manufacturing, the selection of a reliable conveyor belts supplier is pivotal. Conveyor belts play a crucial role in facilitating the movement, processing, and packaging of tobacco products. Thus, selecting the appropriate tobacco conveyor belts supplier for these essential components is paramount for ensuring efficiency and quality within the manufacturing process.

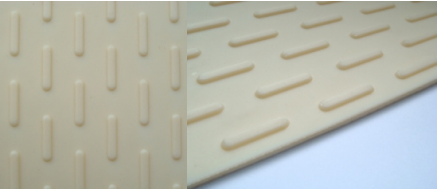

Quality and Durability of Conveyor Belts

The quality and durability of conveyor belts are foundational considerations. The materials used in their construction, such as FDA-approved rubber or specialized synthetic compounds, should resist wear, tear, and corrosion induced by tobacco materials. Furthermore, examining the tobacco conveyor belts supplier’s adherence to stringent testing standards and certifications ensures durable and reliable conveyor belts suitable for the tobacco industry’s demands.

Customization and Adaptability

A reputable conveyor belts supplier should offer customized solutions tailored to specific manufacturing needs. The ability to adapt conveyor belt designs to accommodate varying production processes and layouts is essential. Whether for loose leaf processing, cigarette manufacturing, or packaging, the tobacco conveyor belts supplier should provide tailored solutions to optimize efficiency and effectiveness.

Compliance with Industry Regulations and Safety Standards

Compliance with industry-specific regulations and safety standards is non-negotiable in the tobacco manufacturing sector. Tobacco conveyor belts suppliers must adhere to stringent guidelines and certifications to ensure the conveyor belts meet health, safety, and environmental standards. Ensuring legal compliance guarantees the manufacturing facility operates within regulatory frameworks, mitigating risks and liabilities.

Reliability and Performance

A tobacco conveyor belts supplier’s track record and reputation for reliability are key indicators of performance. The conveyor belts’ operational metrics—such as speed, precision, and efficiency—should align with the manufacturing facility’s requirements. Case studies or testimonials illustrating successful installations and long-term reliability further affirm the tobacco conveyor belts supplier’s performance capabilities.

Maintenance and Support Services

Beyond the initial purchase, a reliable tobacco conveyor belts supplier should offer comprehensive maintenance services and technical support. Training programs for the facility’s staff on conveyor belt operation and maintenance contribute to prolonged equipment life and optimized performance. Understanding warranty policies, repair services, and replacements offered by the tobacco conveyor belts supplier ensures continued operational efficiency.

Cost Considerations and Value

While cost is a significant factor, evaluating the tobacco conveyor belts supplier’s proposition in terms of durability, maintenance, and efficiency is crucial. Assessing the long-term value provided by high-quality conveyor belts versus initial costs is essential. Often, investing in superior-quality belts might result in reduced operational costs and higher productivity over time.

Environmental Impact and Sustainability

The environmental impact of conveyor belt materials and manufacturing processes is gaining prominence. Eco-friendly materials and sustainable manufacturing practices should be a consideration. A tobacco conveyor belts supplier’s commitment to reducing environmental impact through recycling programs or responsible disposal practices adds value to their offerings.

Conclusion

Choosing the right tobacco conveyor belts supplier requires a meticulous assessment of various factors. Quality, customization, compliance, reliability, support services, cost considerations, and sustainability aspects collectively contribute to the ideal selection. The tobacco conveyor belts supplier’s capability to align with the manufacturing facility’s specific needs ensures seamless operations and enhanced productivity.