Introduction

Bakery operations rely heavily on efficient conveyor belts and equipment to handle diverse products like bread, pastries, and cakes. Each of these items possesses unique characteristics, requiring specific handling during various stages of production. The selection of suitable conveyor belts and equipment tailored to the distinct requirements of bakery products significantly influences productivity, quality, and adherence to food safety standards.

Understanding Bakery Product Requirements

Different bakery products necessitate individualized handling due to their specific characteristics. Bread, for instance, requires conveyors and equipment capable of handling large quantities of dough while maintaining consistent temperature and humidity levels during proofing and baking. Pastries, with their delicate nature, demand gentle handling to avoid deformation, making non-stick surfaces and adjustable speed crucial. Cakes need specialized equipment for precise mixing, baking, and cooling to maintain their texture and structure.

Considerations for Conveyor Belts and Equipment Selection

- Hygiene and Food Safety

In bakery operations, maintaining impeccable hygiene and adhering to stringent food safety standards are non-negotiable. Conveyor belts and equipment must meet specific criteria to ensure product integrity and compliance with regulatory requirements. Materials used in manufacturing conveyor belts, such as food-grade stainless steel, FDA-approved plastics, or antimicrobial coatings, play a pivotal role in preventing contamination. Conveyor designs with seamless surfaces, fewer crevices, and easy-to-clean features mitigate the risk of bacterial growth or product contamination. Moreover, equipment designed with sanitary principles in mind ensures hygienic handling from dough preparation to final packaging, instilling consumer trust in the product’s safety.

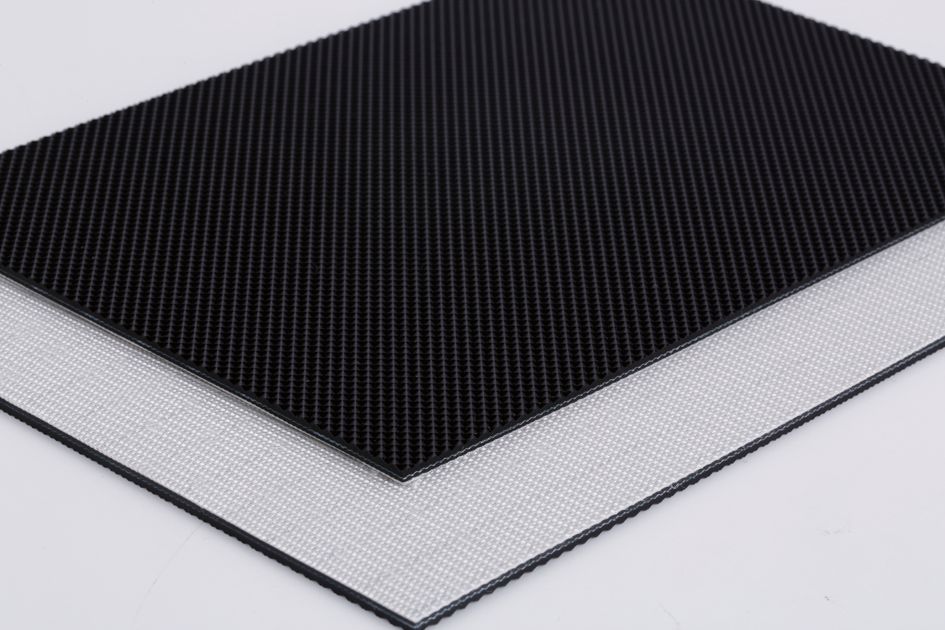

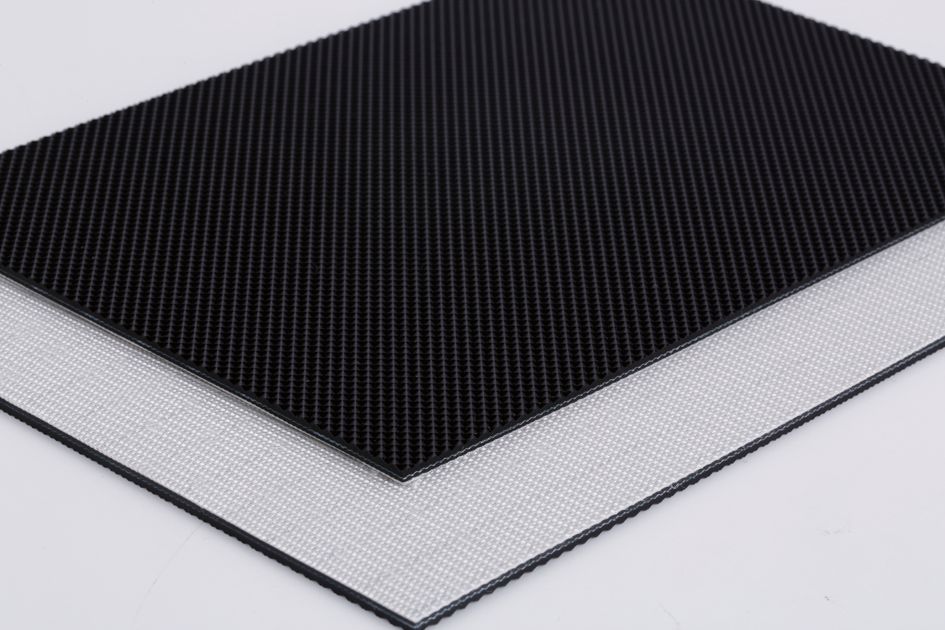

- Product Handling and Surface Characteristics

Different bakery products necessitate varying handling characteristics during processing. For instance, bread dough requires robust handling due to its substantial weight and high moisture content. Conveyor belts featuring robust structures and high load-bearing capacity are ideal for handling bread dough during mixing, proofing, and baking stages. Conversely, delicate pastries and cakes demand gentle handling to maintain their structure and appearance. Non-stick surfaces, soft belts, or adjustable speed controls on conveyors are crucial to prevent product damage or deformation. Customized conveyor designs with adjustable width or modular components accommodate varying product sizes, shapes, and weights, ensuring efficient and damage-free transportation throughout the production line.

- Temperature Control and Baking Processes

Temperature control is critical in bakery operations, particularly during proofing and baking stages. Conveyor belts and equipment must facilitate precise temperature control to ensure consistent product quality. Ovens equipped with accurate temperature sensors, controlled humidity, and adjustable conveyor speeds cater to the specific requirements of different bakery products. Heat-resistant conveyor belts capable of withstanding high temperatures without affecting product quality are essential for conveying products through baking processes. Automated systems with precise temperature and humidity controls maintain uniform baking or proofing conditions, ensuring consistent quality across batches.

- Customization and Flexibility

The versatility of conveyor belts and equipment plays a vital role in optimizing bakery operations. Customization and flexibility are key considerations, especially in accommodating diverse bakery product requirements. Modular conveyor systems that allow easy adjustment of belt widths, heights, or configurations cater to various product sizes and shapes. Adjustable speed controls enable fine-tuning of the production process, facilitating smoother transitions between different stages of production. Flexible layouts and configurations in equipment design streamline operations, ensuring adaptability to changing production needs without compromising efficiency.

- Efficiency and Throughput

Selecting conveyor belts and equipment that enhance operational efficiency and throughput is essential in bakery plants. Equipment with features like automated loading and unloading mechanisms, efficient product transfer systems, and streamlined conveyor layouts optimize workflow and minimize production bottlenecks. Adjustable conveyor speeds synchronized with baking or proofing times improve efficiency without compromising product quality. Automated systems reduce manual intervention, increasing production rates while maintaining consistent product standards.

Case Studies or Examples

- Bread Production Efficiency Enhancement

In a large-scale bakery specializing in bread production, the implementation of customized conveyor belts and equipment significantly enhanced operational efficiency. The bakery opted for heavy-duty conveyor belts with robust structures capable of handling large batches of bread dough. These conveyor belts were integrated into a dough handling system that included mixers, proofers, and ovens, all synchronized for seamless processing. The use of high-load-bearing belts reduced product handling time by 30%, streamlining the movement of dough from mixing to baking stages. This improvement not only increased productivity by 25% but also resulted in consistent product quality and reduced energy consumption due to optimized oven loading.

- Delicate Product Handling in Pastry Production

In a pastry manufacturing facility, the challenge lay in handling delicate pastries without compromising their integrity. The bakery installed specialized conveyor belts featuring soft, non-stick surfaces to transport pastries through various stages of production. These belts were equipped with adjustable speed controls to ensure gentle handling, preventing deformation or damage to the delicate products. The implementation of these customized conveyor belts reduced product wastage by 40% and minimized the need for manual handling, contributing to a significant improvement in product quality and operational efficiency.

- Temperature-Controlled Cooling for Cakes

A cake production facility faced issues with maintaining consistent product quality during the cooling process. To address this, the bakery invested in temperature-controlled cooling conveyors specifically designed for cakes. These conveyors allowed precise adjustment of cooling temperatures and airflow, ensuring gradual and uniform cooling of cakes after baking. The implementation resulted in a 50% reduction in cake deformation and improved texture consistency. The bakery observed a remarkable decrease in product rejects and customer complaints related to uneven cooling, leading to enhanced customer satisfaction and brand reputation.

- Customized Modular System for Diverse Products

In a bakery producing a wide range of products, the adoption of a modular conveyor system brought significant improvements in operational flexibility and efficiency. The bakery opted for a versatile conveyor system with adjustable widths, heights, and speed controls to accommodate various product sizes and shapes, including bread, pastries, and cakes. This customization allowed seamless transitions between different product lines without requiring extensive reconfiguration. As a result, production changeovers were reduced by 40%, maximizing equipment utilization and minimizing downtime.

- Automated Handling for Enhanced Throughput

An artisanal bakery aiming to scale up production efficiency introduced automated handling systems integrated with conveyor belts. The incorporation of automated loading and unloading mechanisms synchronized with conveyor speeds streamlined the production process for artisanal bread. This innovation led to a 30% increase in throughput without compromising the handcrafted quality of the bread. The bakery achieved higher production volumes while maintaining the artisanal touch that resonated well with customers, leading to increased market share and profitability.

Maintenance and Optimization

Maintenance of bakery equipment involves regular inspections, cleaning routines, and preventive maintenance schedules. Proper lubrication and periodic adjustments enhance equipment longevity and performance. Specific cleaning protocols ensure that conveyor belts and equipment meet hygiene standards.