Introduction

Conveyor belts are an integral part of numerous industries, facilitating the efficient movement of materials and products. From manufacturing and mining to food processing and packaging, conveyor belts play a crucial role in streamlining operations and enhancing productivity. As technology and materials continue to advance, TPU (Thermoplastic Polyurethane) conveyor belts have emerged as a superior alternative to traditional conveyor belts. This article aims to explore the advantages of using TPU polyurethane conveyor belts over their traditional counterparts.

Material Composition and Properties

- TPU Polyurethane

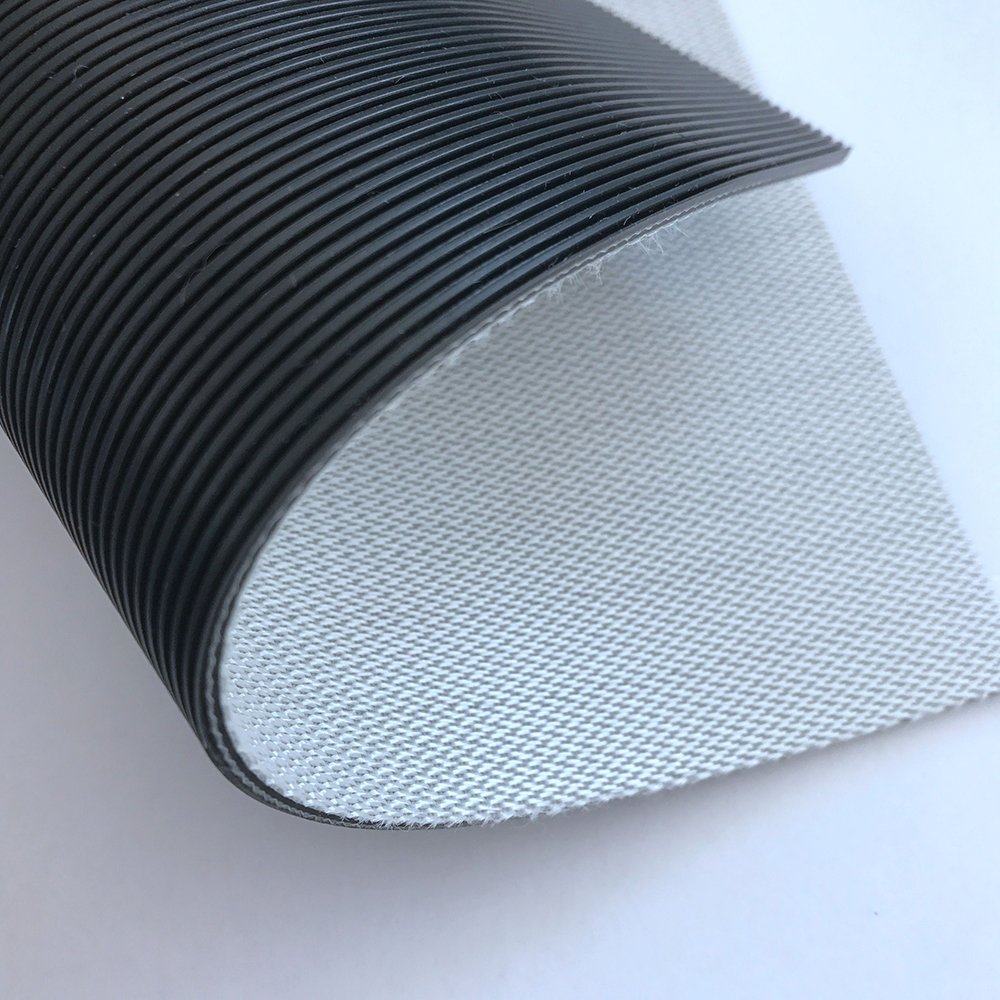

Thermoplastic Polyurethane (TPU) is a versatile material renowned for its exceptional properties, making it a popular choice for various industrial applications. TPU is a type of polyurethane plastic that combines the best properties of plastic and rubber, offering a unique balance of flexibility, durability, and resistance to wear and tear.

- Traditional Conveyor Belts

Traditional conveyor belts are often made from materials like rubber, PVC, or fabric-reinforced rubber. While these materials have been used for many years and are suitable for certain applications, they come with their limitations in terms of durability, flexibility, and resistance to various environmental factors.

Advantages of TPU Polyurethane Conveyor Belts

- Durability and Longevity

One of the most significant advantages of TPU polyurethane conveyor belts is their exceptional durability and longevity. TPU’s inherent resistance to abrasion and wear ensures that these conveyor belts can withstand the rigors of continuous use in demanding industrial environments.

Resistance to wear and tear: TPU polyurethane conveyor belts are highly resistant to abrasion, making them ideal for applications that involve the transportation of abrasive materials or continuous operation over rough surfaces.

Extended lifespan: Due to their superior durability, TPU polyurethane conveyor belts typically have a longer lifespan compared to traditional conveyor belts, reducing the frequency of replacements and associated downtime.

- Flexibility and Adaptability

TPU polyurethane conveyor belts offer greater flexibility and adaptability compared to traditional conveyor belts, allowing them to handle complex shapes and contours more effectively.

Ability to handle complex shapes and contours: The flexibility of TPU polyurethane allows for the creation of conveyor belts with intricate designs and profiles, making them suitable for a wide range of conveyor applications, including those requiring tight turns and complex routing.

Suitable for a variety of conveyor applications: TPU polyurethane conveyor belts are versatile and can be tailored to meet the specific requirements of various industries, including food processing, pharmaceuticals, automotive, and more.

- Resistance to Oils, Chemicals, and Abrasion

TPU polyurethane conveyor belts exhibit superior resistance to oils, chemicals, and abrasion compared to traditional conveyor belt materials.

Superior resistance to oils and chemicals: TPU polyurethane is inherently resistant to a wide range of oils and chemicals, reducing the risk of degradation and ensuring consistent performance in challenging environments.

Reduced maintenance and replacement costs: The enhanced resistance to abrasion and chemical exposure of TPU polyurethane conveyor belts results in reduced maintenance requirements and longer intervals between replacements, leading to cost savings over time.

- Temperature Resistance

Another notable advantage of TPU polyurethane conveyor belts is their excellent temperature resistance, allowing them to maintain flexibility and strength even in extreme temperature conditions.

Performance in extreme temperature conditions: TPU polyurethane conveyor belts can withstand a wide range of temperatures, from freezing cold to high heat, without compromising their performance or mechanical properties.

Maintains flexibility and strength: Unlike some traditional conveyor belt materials that may become brittle or lose their flexibility at extreme temperatures, TPU polyurethane retains its flexibility and strength, ensuring reliable performance in all conditions.

- Reduced Noise and Vibration

TPU polyurethane conveyor belts are designed to reduce noise and vibration, providing a more comfortable and productive working environment.

Noise reduction benefits in conveyor operations: The inherent properties of TPU polyurethane help dampen noise and vibration generated during conveyor operations, contributing to a quieter and more pleasant working environment.

Improved working environment: The reduced noise and vibration levels associated with TPU polyurethane conveyor belts can lead to improved working conditions, increased operator comfort, and enhanced overall productivity.

Comparison with Traditional Conveyor Belts

- Material Limitations of Traditional Conveyor Belts

Traditional conveyor belts, often made from rubber, PVC, or fabric-reinforced rubber, come with their set of limitations.

Common issues such as brittleness, stretching, and tearing: Traditional conveyor belts are prone to brittleness, especially at extreme temperatures, and may stretch or tear under heavy loads or abrasive materials, leading to frequent maintenance and replacement.

- Maintenance and Replacement Costs

Due to their inferior durability and resistance to wear and tear, traditional conveyor belts generally require more frequent maintenance and replacement, resulting in higher operational costs and increased downtime.

Higher maintenance and replacement frequency: The shorter lifespan and higher susceptibility to wear and tear of traditional conveyor belts necessitate more frequent maintenance and replacement, leading to increased operational costs and downtime.

- Performance in Challenging Environments

Traditional conveyor belt materials often struggle to maintain consistent performance in challenging environments characterized by extreme temperatures, exposure to oils and chemicals, or abrasive materials.

Issues with temperature resistance and chemical exposure: Traditional conveyor belt materials may become brittle, lose flexibility, or degrade when exposed to extreme temperatures, oils, or chemicals, compromising their performance and reliability.

Conclusion

In conclusion, TPU polyurethane conveyor belts offer a range of significant advantages over traditional conveyor belts, making them an increasingly preferred choice for various industries and applications.

Recap of the key advantages of TPU polyurethane conveyor belts over traditional conveyor belts: From superior durability and longevity to enhanced flexibility, resistance to oils, chemicals, and temperature extremes, and reduced noise and vibration levels, TPU polyurethane conveyor belts excel in multiple areas compared to traditional conveyor belt materials.

Summary of the potential benefits for industries and applications: The unique properties and advantages of TPU polyurethane conveyor belts translate into tangible benefits for industries, including reduced maintenance and replacement costs, increased operational efficiency, and improved working conditions.

Final thoughts on the growing preference for TPU polyurethane conveyor belts in the industry: As industries continue to prioritize efficiency, reliability, and safety, the growing preference for TPU polyurethane conveyor belts over traditional conveyor belts is expected to continue, driven by their superior performance, du