Introduction

Felt sanding belts stand out as versatile tools in sanding applications, offering distinct advantages over conventional abrasive belts. Understanding their unique properties and differences from traditional abrasives is crucial for optimizing sanding processes across various industries.

Understanding Felt Sanding Belts

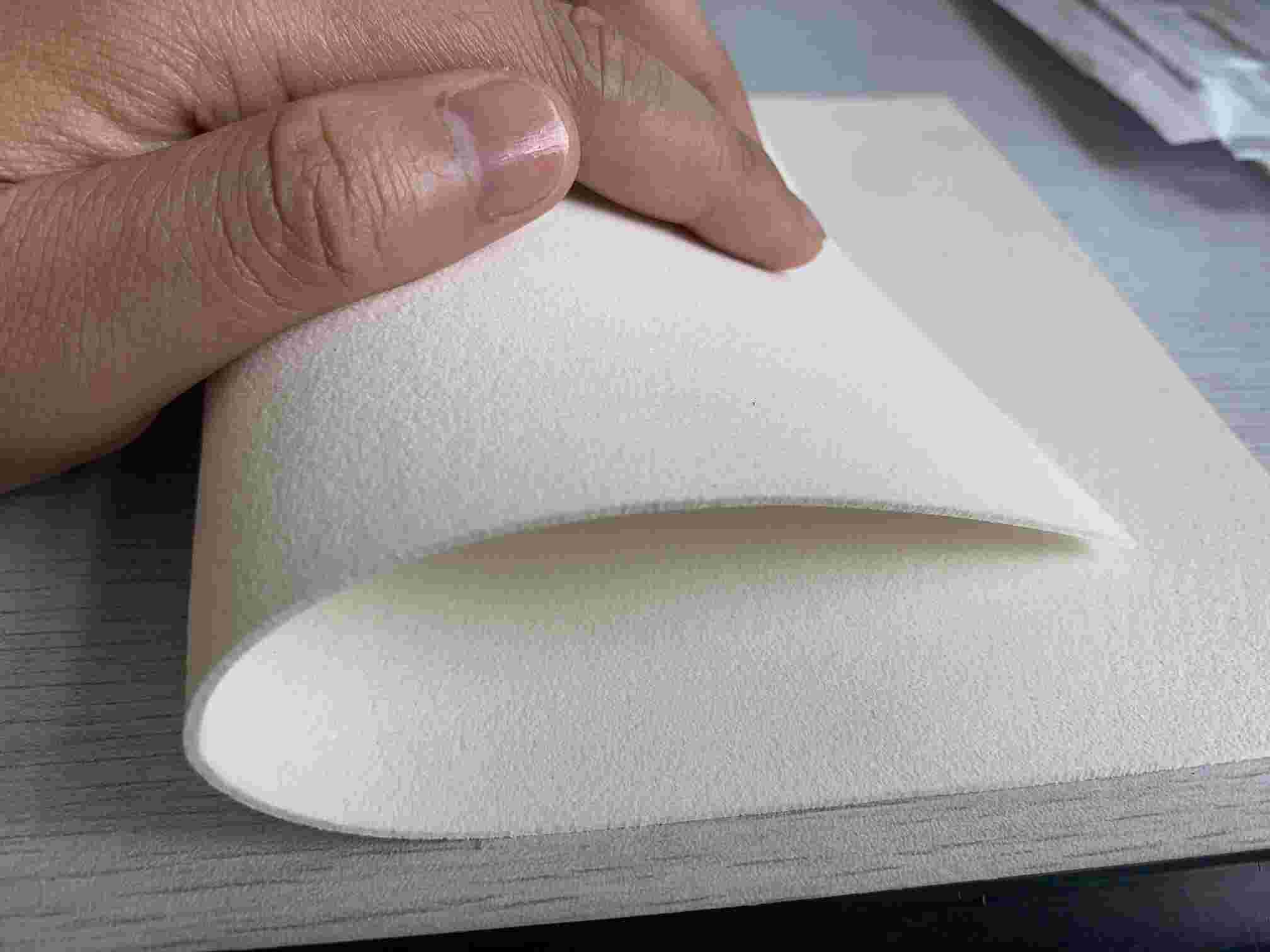

Felt sanding belts, often crafted from wool or synthetic fibers like polyester or wool blends, represent a specialized category of abrasive belts distinct in their construction and sanding capabilities. These belts are meticulously crafted by binding abrasive particles into a dense and resilient felt base, creating a surface uniquely suited for various sanding tasks.

- Construction and Materials

Felt sanding belts are primarily composed of densely compacted fibers, which create a soft and flexible base. These fibers, typically wool or synthetic materials, are interlocked and compressed to form a resilient yet pliable structure. Manufacturers combine these fibers with abrasive particles, such as aluminum oxide, silicon carbide, or ceramic grains, embedding them within the felt matrix.

- Characteristics and Texture

The inherent softness and cushioning effect of the felt material distinguish felt sanding belts from conventional abrasive belts. This characteristic texture allows the belt to contour intricately shaped workpieces, conforming closely to various surfaces without causing gouging or uneven abrasion. Additionally, the cushioned texture ensures more consistent pressure distribution during sanding, reducing the risk of uneven surface treatment.

- Versatility and Adaptability

Felt sanding belts showcase remarkable adaptability across different applications and materials. Their pliable nature allows them to conform adeptly to irregular contours, intricate profiles, and delicate surfaces, ensuring uniform abrasion without compromising the workpiece’s integrity. This adaptability enables efficient and precise sanding in areas that might be inaccessible to rigid abrasive belts, making them invaluable for detailed and fine surface treatments.

- Heat Resistance and Sanding Precision

The structure of felt sanding belts exhibits excellent heat dissipation properties. This characteristic minimizes the risk of heat build-up during prolonged sanding sessions, preserving the integrity of both the abrasive belt and the workpiece. Moreover, their cushioned texture and reduced friction ensure controlled and precise material removal, contributing to achieving finer finishes and polished surfaces.

- Specialized Applications and Functions

Felt sanding belts find extensive application in various industries requiring intricate surface treatments, finishing, and polishing. Their effectiveness spans woodworking, metalworking, knife sharpening, glass fabrication, and specialized applications where achieving refined surface quality and precision are paramount.

Understanding the unique construction, characteristics, and sanding capabilities of felt sanding belts is essential for optimizing their usage across diverse industries and applications, ensuring superior surface treatments, and achieving desired finishing results. Their distinctive properties make them indispensable tools for achieving intricate and fine surface treatments that conventional abrasive belts might not efficiently accomplish.

Unique Properties of Felt Sanding Belts

- Surface Texture and Composition

Felt sanding belts exhibit a soft and cushioned surface texture due to the intertwined fibers, which aids in achieving smoother finishes and delicate surface treatments. The composition of these belts contributes to their adaptability to various shapes and contours, offering greater precision in sanding intricate surfaces.

- Adaptability and Flexibility

Their pliable nature allows felt sanding belts to conform closely to irregular shapes and contours, enabling effective sanding in areas that might be challenging for rigid abrasive belts. This adaptability ensures thorough and consistent sanding across diverse surfaces.

- Heat Resistance and Polishing Ability

The unique structure of felt sanding belts minimizes heat generation during sanding operations, reducing the risk of heat-related damage to workpieces. Furthermore, their polishing capabilities contribute to achieving fine finishes and refined surfaces, making them ideal for applications requiring a high level of surface smoothness.

Differences Between Felt Sanding Belts and Conventional Abrasive Belts

- Material Composition

Unlike conventional abrasive belts primarily made of abrasive minerals bonded to a backing material, felt sanding belts incorporate abrasive particles within a felt base. This distinct composition provides a softer and more cushioned sanding surface.

- Sanding Mechanism

Felt sanding belts operate by conforming and adjusting to the surface, utilizing the felt material’s texture to achieve sanding and polishing actions. In contrast, conventional abrasive belts rely on a harder, fixed surface for abrasion.

- Application Range

Felt sanding belts excel in providing fine finishes and precise surface treatments, particularly in woodworking, metalworking, and specialized applications requiring delicate sanding. Conventional abrasive belts are versatile but might lack the finesse and polishing capabilities of felt belts in certain applications.

Advantages of Felt Sanding Belts Over Conventional Abrasives

- Superior Finish and Polishing

The soft surface of felt sanding belts contributes to achieving exceptionally smooth finishes, making them a preferred choice for applications where a refined surface quality is crucial.

- Reduced Heat Generation

The cushioned nature of felt sanding belts minimizes frictional heat during sanding, preserving the integrity of the workpiece and reducing the risk of heat-related damage.

- Adaptability to Various Materials

Felt sanding belts demonstrate effectiveness across different materials, including wood, metal, plastics, and composites, owing to their adaptable and gentle sanding action.

Industrial Applications and Usage Scenarios

Industries Where Felt Sanding Belts Excel

Felt sanding belts find extensive use in woodworking, precision metalworking, knife sharpening, and applications requiring intricate surface treatments and polishing.

- Specific Usage Scenarios

In woodworking, felt sanding belts excel in finishing tasks, such as smoothing curved surfaces and achieving refined profiles. In metalworking, they aid in polishing and refining metal surfaces without causing damage.

- Success Stories or Case Studies

Case studies showcasing the successful use of felt sanding belts in achieving superior finishes, precise polishing, and intricate surface treatments in various industries.

Conclusion

Felt sanding belts stand out as specialized tools offering unique benefits in sanding applications. Their distinct properties, including surface texture, adaptability, heat resistance, and polishing capabilities, set them apart from conventional abrasive belts. Understanding these differences is essential for selecting the appropriate belt for specific sanding tasks, ensuring superior results and optimized surface treatments across diverse industries.