Product characteristics

Efficient cooling and heating: The water-cooled heat exchanger uses an efficient heat exchanger, which can achieve fast and stable cooling and heating effects and improve production efficiency and product quality.

Safe and stable: Water-cooled and hot connectors adopt advanced safety protection measures, such as overheating protection, pressure protection, water level protection, etc., to ensure safe and reliable operation of the equipment and reduce the incidence of accidents.

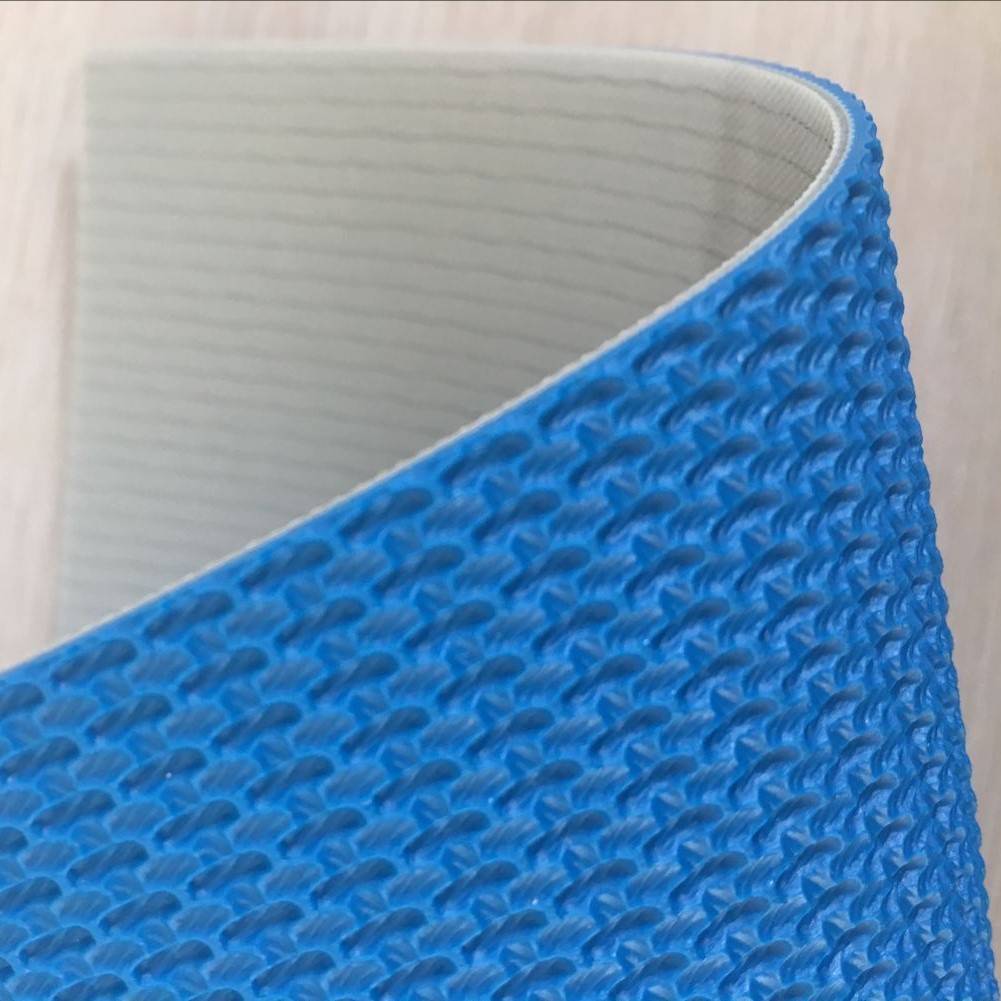

Good stability: The water-cooled hot coupler uses high-quality materials and manufacturing technology, has good stability and durability, can operate stably for a long time, and reduces maintenance costs.

Easy to operate: The water-cooled and hot coupler has a simple and easy-to-understand operation interface. It can easily set parameters such as flow and temperature to achieve one-click start and stop, reducing operation difficulty and error rate.

Environmental protection and energy saving: The water-cooling and heating connectors use advanced refrigeration and heating technology. They have the characteristics of high efficiency, energy saving and environmental protection, and can reduce energy consumption and pollution emissions.

Customizable: Water cooling and hot connectors can be customized according to your specific needs, including equipment size, flow control, pump type, control system, etc., to meet your different needs.

Product application

Water-cooled hot connectors are widely used in air conditioning, cold storage, industrial production and other fields.

Air conditioning industry: Water cooling and hot water connectors can be used in chillers and hot water units in central air conditioning systems to meet the cooling and heating needs of buildings.

Cold storage industry: Hot and cold water connectors can be used in the cooling and heating processes of cold storage for food, pharmaceuticals, etc., to ensure product quality and safety.

Industrial production: Water-cooled hot and cold connectors can be used in refrigeration and heating processes in various industrial production, such as chemical, pharmaceutical, electronics and other industries.

Product model

Light water cooling and hot water connection: suitable for small air conditioners, cold storage and other scenarios, with a cooling capacity between 5-30KW.

Medium-sized water cooling and hot water supply: suitable for medium-sized air conditioning, cold storage and other scenarios, with a cooling capacity between 30-80KW.

Large water cooling and hot water supply: suitable for large air conditioning, cold storage and other scenarios, with a cooling capacity between 80-500KW.

Product installation and maintenance

Installation: Hot and cold water connectors should be installed on well-ventilated, dry and flat ground, away from high temperature, humidity, flammable and other environments. Before installation, check whether the equipment and piping are in good condition, fix the equipment and pipelines, and ensure that the installation is secure.

Maintenance: The maintenance of hot and cold water connectors should be carried out regularly, including cleaning the water tank, replacing filters, and checking the operating status of equipment such as pumps and valves. During maintenance, you should pay attention to safety to avoid accidents.

FAQ

What is the working principle of a water-cooled hot and cold splice machine?

Water cooling and hot connectors mainly use a water pump to extract the coolant or heat medium from the water tank, cool or heat it through a heat exchanger, and then adjust the flow through a flow control valve to send the coolant or heat medium back to the water tank to form a cycle. In this process, a heat exchanger transfers heat to a coolant or heat medium to achieve the purpose of cooling or heating.

How to choose the cooling capacity of a water-cooled hot and cold water dispenser?

The cooling capacity of water-cooled hot and cold connectors should be selected according to actual needs. Generally, it is recommended to choose a model with a cooling capacity slightly larger than the actual required cooling capacity. If the cooling volume selected is too small, the equipment will not be able to meet actual needs, which will affect production efficiency and product quality; if the cooling volume chosen is too large, energy will be wasted and costs will increase.

What should I pay attention to in the maintenance of hot and cold water connectors?

Maintenance of hot and cold water connections should be carried out regularly, including cleaning the water tank, replacing filters, and checking the operating status of equipment such as pumps and valves. During maintenance, you should pay attention to safety to avoid accidents. At the same time, care should be taken to prevent problems such as water pollution and pipeline leaks to ensure the normal operation of the equipment.

What is the service life of a water-cooled hot and cold connector?

The service life of hot and cold water connectors depends on factors such as the manufacturing quality, usage environment, and maintenance of the equipment. Generally, the service life of hot and cold water couplings can reach more than 10 years, but only if regular maintenance and maintenance are carried out.

How to deal with the failure of the water-cooled hot and cold connecting machine?

If the hot and cold water connector fails, you should promptly contact the equipment manufacturer or professional maintenance company for repair. Before maintenance, equipment should be shut down and inspected first, the cause of the fault should be found out as much as possible, and corresponding records should be made. During the maintenance process, you should pay attention to safety to avoid accidents.

Contact us

If you need more information about hot and cold water transfers, or if you have any questions or suggestions, please don’t hesitate to contact us and we will be happy to help you.

Email: [email protected]

Contact number: +86-510-83312052

Contact address: 288, Fengyang Roda, Luoshe Development Zone, Wuxi, China