Product composition:

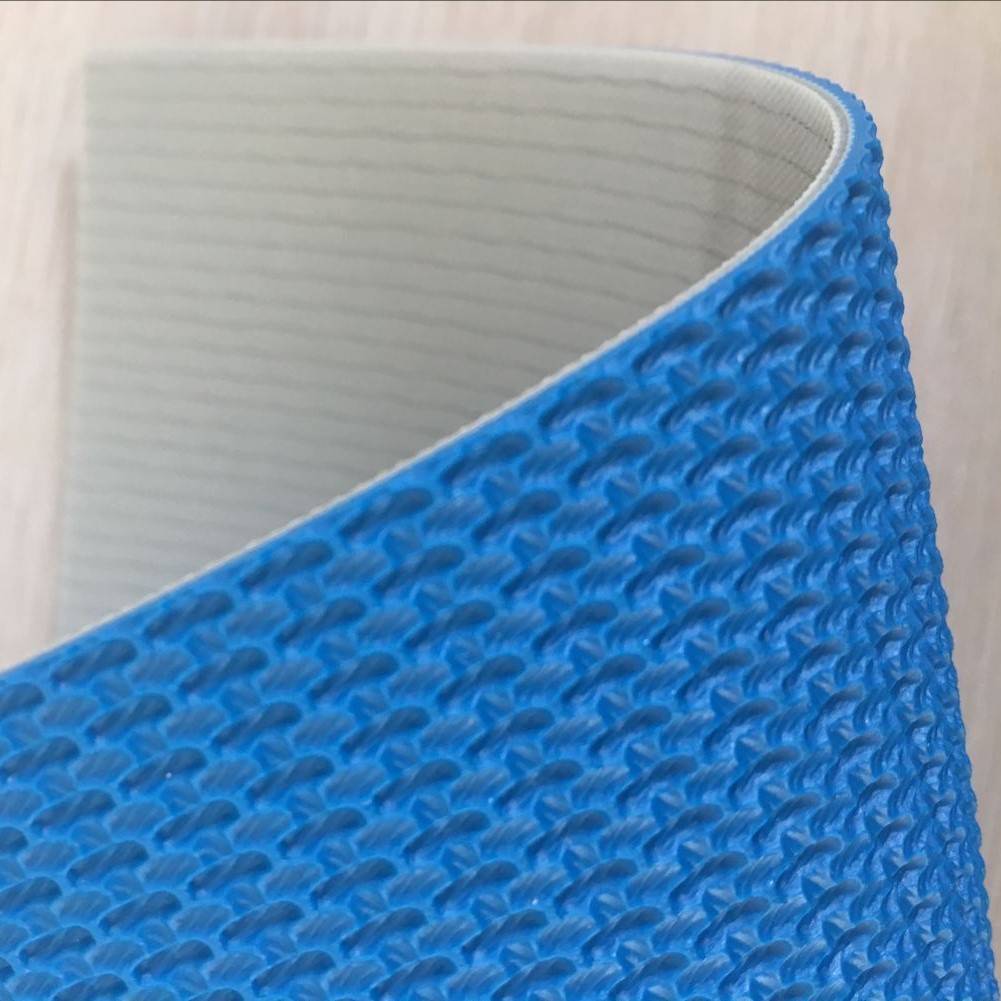

Slippy PU Mattress Belt For Mattress Industry is made of high-quality polyurethane (PU) material, the surface is covered with non-slip material, the interior is made of polyester fiber-reinforced canvas, and a specially treated adhesive layer.

Product features:

Strong anti-slip performance: The surface of Slippy PU Mattress Belt For Mattress Industry is covered with anti-slip material, which can effectively prevent the mattress from slipping during transportation and ensure safety and stability.

Wear resistance: Slippy PU Reinforced Canvas is made of PU material and polyester fiber-reinforced canvas, which has high wear resistance and can withstand long periods of use and wear.

High temperature resistance: Slippy PU Belts can operate at higher temperatures, with a temperature range of -35℃ to 80℃, suitable for a variety of environments.

EASY TO CLEAN: The Slippy PU Conveyor Belt has a smooth and flat surface that is easy to clean and disinfect, keeping the transportation process hygienic and safe.

Environmentally friendly and reliable: Slippy PU Belts are made of environmentally friendly materials, meet relevant environmental standards and requirements, and are reliable and stable.

Unveiling the Slippy PU Conveyor Belt

What is the Slippy PU Conveyor Belt?

The Slippy PU Conveyor Belt is a high-quality polyurethane conveyor belt engineered specifically for the mattress industry. Its primary function is to move materials efficiently from one point to another within a manufacturing facility. Unlike traditional conveyor belts, the Slippy PU Conveyor Belt is designed to reduce friction, leading to smoother and more productive production processes.

Key Attributes

High-Quality Polyurethane: Crafted from premium polyurethane material, this conveyor belt boasts exceptional durability and wear resistance. Its robust construction ensures a longer lifespan, reducing maintenance and replacement costs.

Low Coefficient of Friction: The Slippy PU Conveyor Belt is characterized by its low coefficient of friction. This attribute minimizes the force required to move materials, reducing wear and tear on the belt and associated machinery.

Mattress Industry Optimization: This conveyor belt is engineered with the mattress manufacturing industry in mind. Its design, materials, and functionality are tailored to the specific needs of mattress production.

Smooth and Silent Operation: The low friction of the Slippy PU Conveyor Belt results in smooth and virtually silent operation. This is particularly advantageous in a busy manufacturing environment where noise reduction is a priority.

Customization Options: The Slippy PU Conveyor Belt can be customized to suit the unique requirements of your mattress manufacturing line. Whether you need a specific width, length, or surface texture, customization options are available.

Functions of the Slippy PU Conveyor Belt

- Smooth Material Transport

One of the primary functions of the Slippy PU Conveyor Belt is to ensure a seamless material transport process. With its low coefficient of friction, it allows materials to glide effortlessly from one end of the production line to the other. This reduces the risk of material jams and bottlenecks, thereby increasing overall efficiency.

- Noise Reduction

In busy manufacturing facilities, noise can be a significant concern. The Slippy PU Conveyor Belt’s smooth and silent operation contributes to a quieter work environment, improving the overall atmosphere for workers and allowing for better communication on the production floor.

- Increased Durability

This conveyor belt’s high-quality polyurethane construction enhances its durability. It can withstand the demands of continuous use, reducing the need for frequent replacements and maintenance. This, in turn, minimizes downtime and production disruptions.

Customization for Varied Applications

The Slippy PU Conveyor Belt is versatile and can be tailored to meet the specific needs of various mattress manufacturing processes. Whether you require a specific width, length, or surface texture, customization options are available to ensure it perfectly aligns with your production requirements.

Cost-Efficiency

By reducing friction and enhancing the longevity of the belt and associated machinery, the Slippy PU Conveyor Belt offers long-term cost savings. Its initial investment is outweighed by the decrease in maintenance and replacement expenses, making it a cost-effective choice for mattress manufacturers.

Advantages of Using the Slippy PU Conveyor Belt for Mattress Manufacturing

- Enhanced Efficiency

Efficiency is the lifeblood of any manufacturing operation, and the Slippy PU Conveyor Belt excels in this regard. Its low friction design minimizes the effort required to move materials, ensuring a continuous and smooth production process. This increased efficiency directly impacts your bottom line, as higher production rates lead to greater output and revenue.

- Improved Product Quality

In the mattress industry, consistency in product quality is essential. The Slippy PU Conveyor Belt’s ability to transport materials without causing damage or disruptions leads to a more consistent manufacturing process. This, in turn, results in mattresses of higher quality, reducing defects and increasing customer satisfaction.

- Reduced Maintenance Costs

One of the most significant advantages of the Slippy PU Conveyor Belt is its long-lasting durability. Its resistance to wear and tear minimizes maintenance requirements, reducing the costs associated with belt replacements and repairs. This reduction in maintenance expenses directly contributes to a healthier bottom line.

- Noise Reduction

The smooth and quiet operation of the Slippy PU Conveyor Belt provides a more comfortable and productive work environment. Reduced noise levels on the production floor can enhance employee morale, productivity, and communication.

- Customization to Fit Your Needs

Every mattress manufacturing facility has unique requirements. The Slippy PU Conveyor Belt can be customized to match your specific needs, ensuring it seamlessly integrates into your production line. Whether you need a specific size, texture, or design, this conveyor belt can be tailored to fit your application perfectly.

Things to note

Before using the Slippy PU Conveyor Belt, make sure the conveying equipment is flat to avoid using it on uneven surfaces.

Do not use sharp or hard objects on the surface of the product to avoid damaging the anti-slip material on the surface.

When cleaning and maintaining this product, do not use strong acids, bases, or organic solvents to avoid damage to the product.

Scope of application

The anti-slip PU conveyor belt used in the mattress industry is suitable for the conveying needs of the mattress manufacturing industry. On the mattress production line, mattresses need to go through a conveyor belt for transportation, assembly, packaging, etc. However, since the surface of mattresses is usually smooth and easily slippery during transportation, it is necessary to use a conveyor with anti-slip properties to ensure the safety and stability of the production process. This product is suitable for a variety of environments, can operate at higher temperatures, has high wear resistance and is easy to clean, and can meet the transportation needs of the mattress manufacturing industry.

Maintenance and care: This product needs to be cleaned and disinfected regularly during use to maintain hygiene and safety. When cleaning, you can use neutral detergent and clean water; do not use strong acids, bases, or organic solvents. When not in use for a long time, please store this product in a dry, cool place away from sun and moisture.

Pu conveyor belt price

When considering PU conveyor belts price for utility and infrastructure maintenance projects, several factors come into play. These include the size and specifications of the conveyor belt, the quality of materials used in its construction, the manufacturer’s reputation and reliability, and the specific requirements of the application.

The PU conveyor belts price can vary significantly depending on these factors. Standard-sized belts with basic specifications may be more affordable, while custom-sized or specialized belts designed for unique applications may command a higher price. Additionally, belts from reputable manufacturers known for their quality and reliability may come with a premium price tag but offer long-term value and durability.

Customer stories

Mattress manufacturer: The company uses non-slip PU conveyor belts used in the mattress industry to transport and assemble mattresses on the production line to ensure the stability and safety of mattresses during transportation.

Hotel supplies company: The company procures non-slip PU conveyor belts used in the mattress industry for the manufacture of hotel mattresses, making mattresses more stable and safe in the production process.

Furniture company: The company uses non-slip PU conveyor belts used in the mattress industry to transport and assemble mattresses on the production line to ensure the stability and safety of mattresses during transportation.

Medical equipment company: The company purchases non-slip PU conveyor belts used in the mattress industry for the manufacture of medical mattresses, which ensures the hygiene and safety of medical equipment.

Home textile company: The company uses non-slip PU conveyor belts used in the mattress industry to transport and assemble mattresses on the production line to ensure the stability and safety of mattresses during transportation, improve production efficiency and product quality, and also reduce damage and waste of mattresses during production and reduce production costs.

Slippy PU Mattress Belt For Mattress Industry is suitable for a variety of environments, can operate at higher temperatures, and has high wear resistance and easy cleaning characteristics, which can meet the transportation needs of the mattress manufacturing industry.