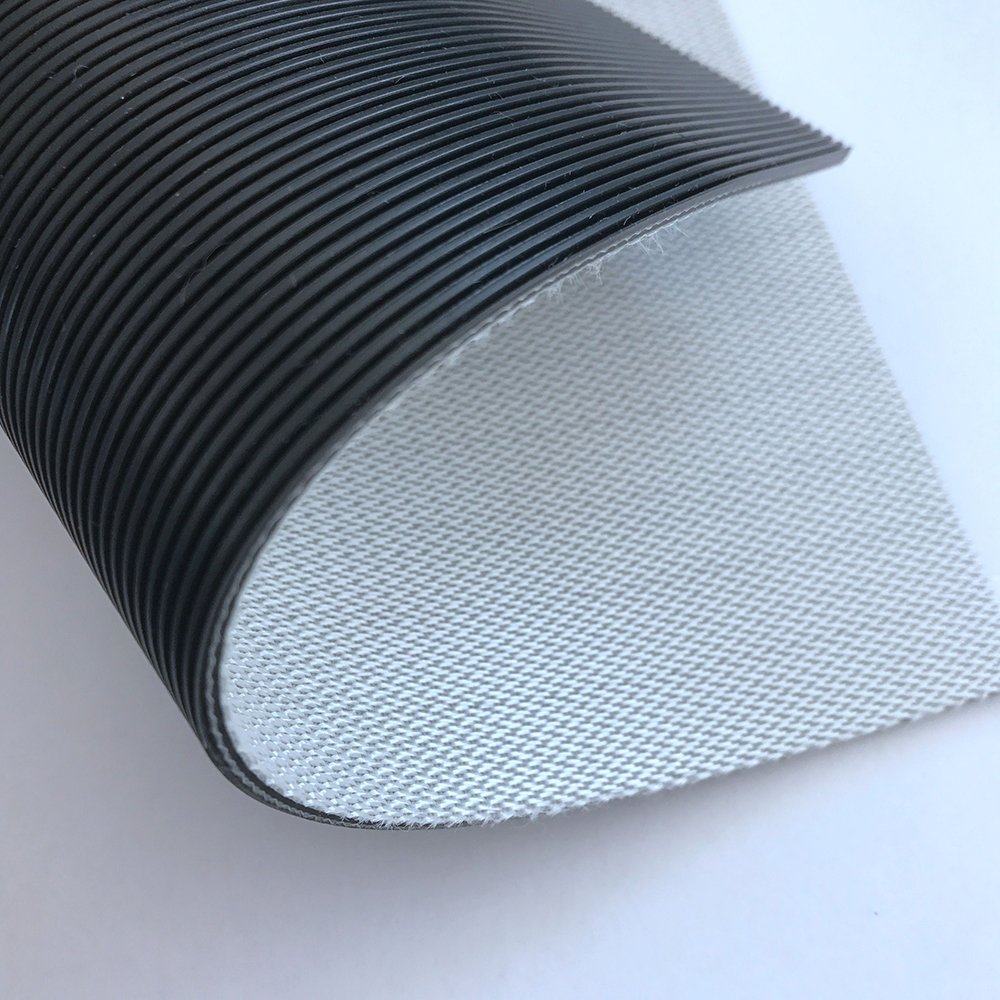

It can press the pattern onto the surface of the conveyor belt, making it have better grip and anti-slip properties. Silicone molds are usually made of high-quality silicone materials, are highly elastic and wear-resistant, and can be used many times without damaging the conveyor belt. The design and manufacture of silicone molds need to take into account factors such as the size, shape, and pattern of the conveyor belt to ensure that the final conveyor belt meets the design requirements.

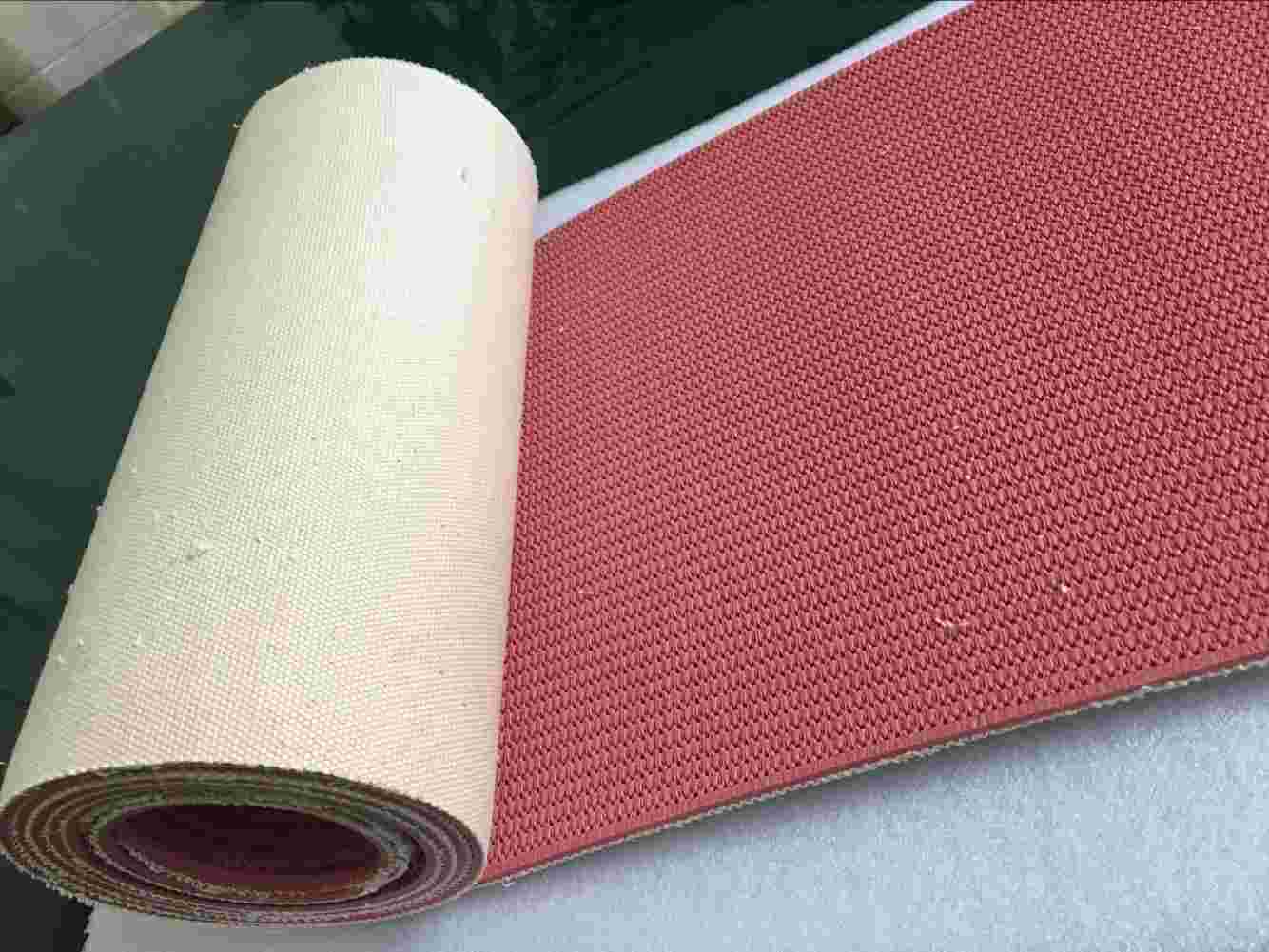

Patterned cloth is a material used to form a pattern on the surface of a conveyor belt. Patterned cloth is usually made of high-strength, wear-resistant materials, such as polyester fiber, nylon fiber, etc. In the manufacturing process, the patterned cloth is placed on a silicone mold, then the conveyor belt material is placed on the patterned cloth, and finally the pattern is pressed onto the surface of the conveyor belt using pressure and heat.

The design and manufacture of silicone molds and patterned cloth requires consideration of many factors, such as the application of the conveyor belt, the size and shape of the pattern, and the elasticity and wear resistance of the silicone mold. Proper design and manufacture can ensure the optimal performance and appearance of the conveyor belt, while also improving production efficiency and reducing costs.

Conveyor belt pattern and application:

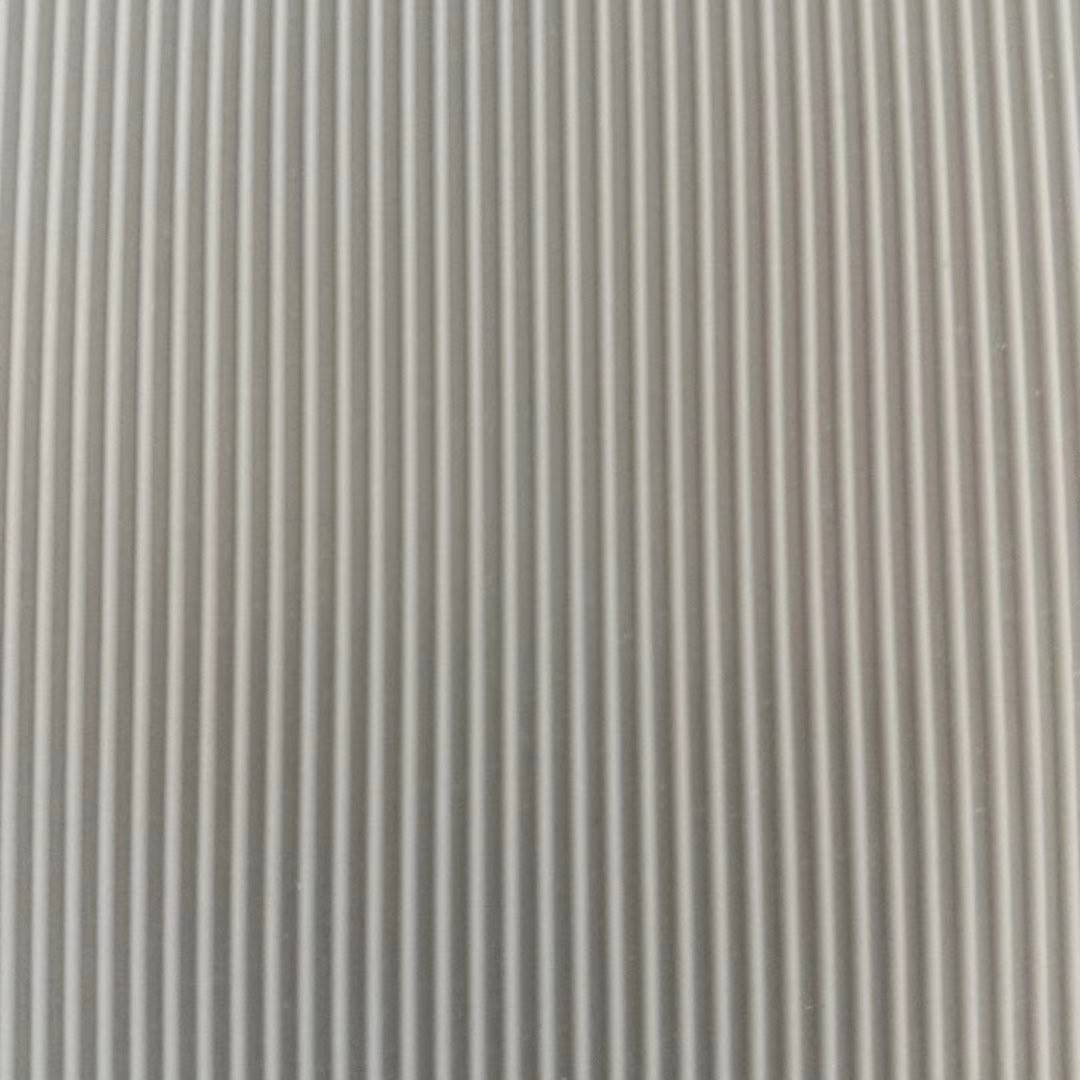

Straight pattern: A straight pattern is a simple pattern, usually used to transport lightweight materials such as food, beverages, paper, etc. This pattern can provide good anti-slip properties while also maintaining the stability of the material.

Trapezoid pattern: A trapezoid pattern is a commonly used pattern, usually used to transport inclined materials such as coal, ore, soil, etc. This pattern provides good anti-slip properties and also prevents the material from sliding or tilting.

Fish bone pattern: Fish bone pattern is a commonly used pattern, usually used to transport heavy materials such as gravel, cement, steel, etc. This pattern provides good anti-slip properties and also prevents the material from sliding or tilting.

V-pattern: V-pattern is a commonly used pattern, usually used to transport sticky materials, such as granular materials, crushed ore, waste, etc. This pattern can provide good anti-slip properties and also promote the flow properties of the material.

Circular pattern: A circular pattern is a commonly used pattern, usually used to transport round materials, such as pipes, tires, metal materials, etc. This pattern can provide good anti-slip properties while also maintaining the stability of the material.

The choice of conveyor belt pattern can affect the conveying effect of materials. Different pattern designs can provide different anti-slip properties, stability and flow properties, thereby affecting the conveying effect of materials. If the wrong pattern design is selected, the material may slide, pile up, tilt, or get stuck, thereby reducing delivery efficiency and production efficiency.

Second, the choice of conveyor belt pattern can affect the wear resistance and life span of the conveyor belt. Different pattern designs use different materials and manufacturing processes, and their wear resistance and longevity are also different. Choosing the wrong pattern design can cause wear and damage to the conveyor belt, which affects production efficiency and cost effectiveness.

Finally, the choice of conveyor belt pattern can also influence cleaning and maintenance during production. Some pattern designs may cause material to remain or accumulate on the conveyor belt, making cleaning and maintenance more difficult and expensive. The right pattern design can reduce the difficulty and cost of cleaning and maintenance, thereby improving production efficiency and cost effectiveness.