Benefits of Sharp nipple belt for vegetables or seafood processing

- Improve efficiency: Pointed conveyors can help you quickly and efficiently transport products such as poultry or seafood to improve production efficiency.

- Cost reduction: The pointed conveyor belt is made of high-quality materials and has the characteristics of wear resistance, corrosion resistance, high temperature resistance, etc., and can be used in harsh environments to reduce maintenance and replacement costs.

- Ensure hygiene: The pointed conveyor belts we provide meet food safety standards, have a smooth surface, are easy to clean and disinfect, avoid bacterial growth and cross-contamination, and ensure food processing hygiene.

- Customized service: We provide customized pointed conveyor belts of different sizes and specifications according to your requirements to meet your specific production needs and provide personalized solutions.

- Good after-sales service: We provide perfect after-sales service and technical support to ensure that the problems you encounter during use are solved in a timely manner and ensure smooth production.

- Improved safety: The pointed conveyor belt we provide has a smooth surface and is not easy to slip and slip, which can effectively prevent hand injuries to workers and improve work safety.

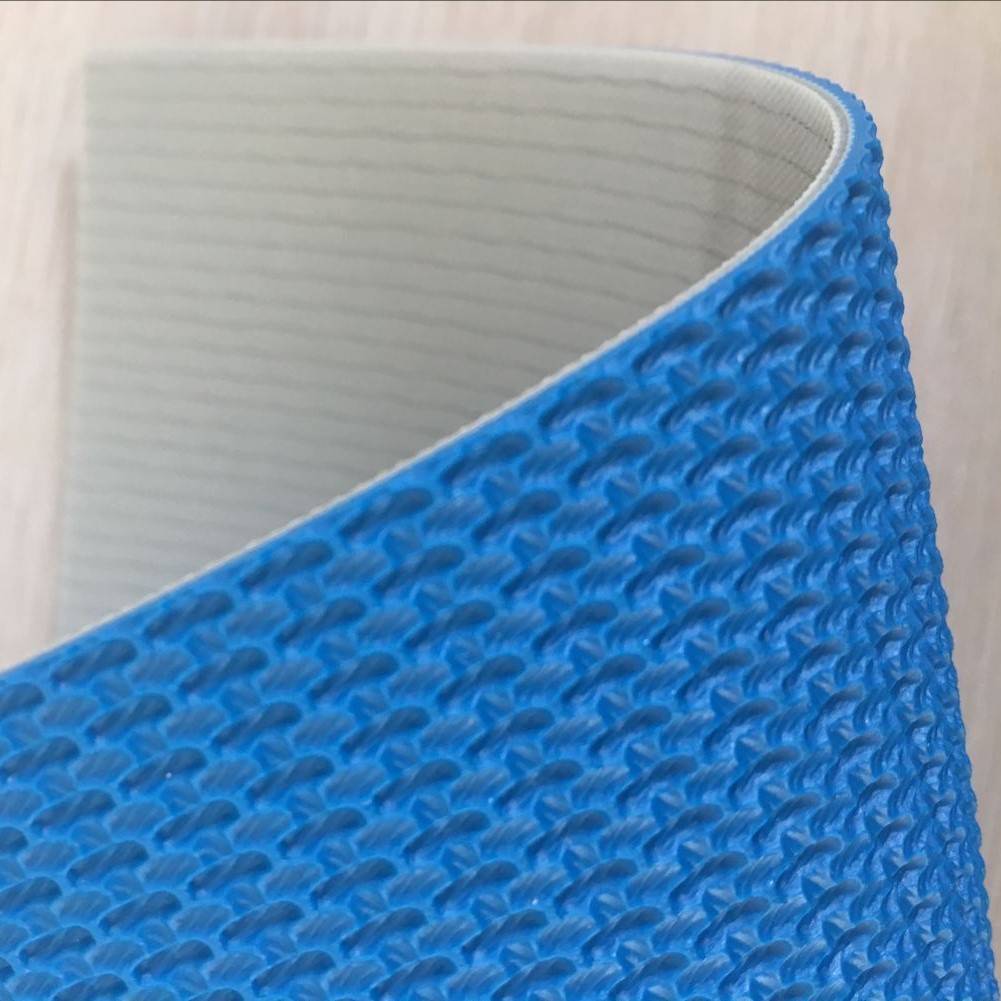

Features of Sharp nipple cooking belt for cooking or seafood processing

- Fast delivery: Pointed conveyors can quickly and efficiently transport products such as poultry or seafood to improve production efficiency.

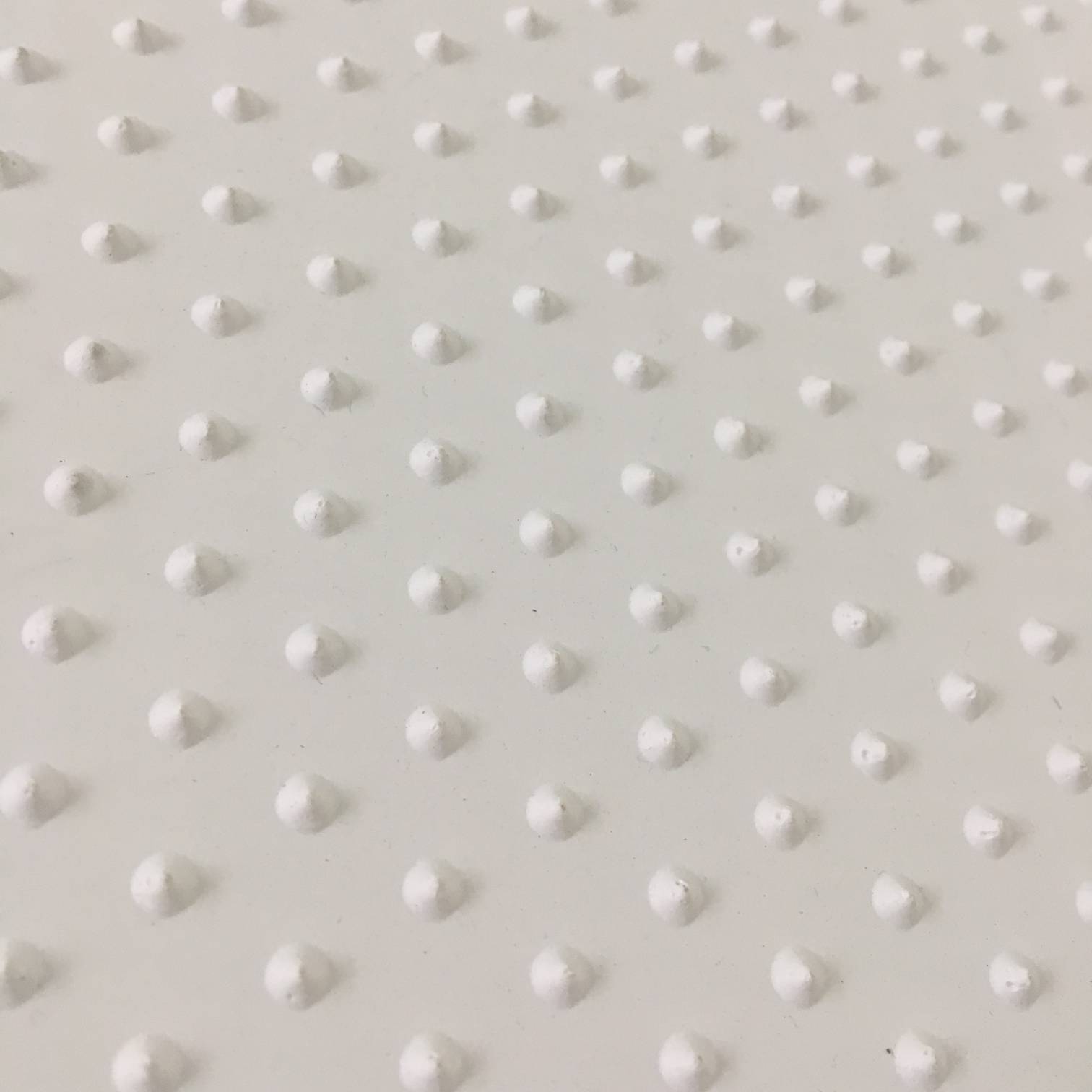

- Anti-slip design: The surface of the pointed conveyor belt has an anti-slip design, which can effectively prevent products from slipping or piling up and ensure production safety.

- Wear and corrosion resistance: The pointed conveyor belt is made of high-quality materials and has characteristics such as wear resistance, corrosion resistance, high temperature resistance, etc., and can be used in harsh environments to reduce maintenance and replacement costs.

- Precise positioning: The pointed design on the pointed conveyor belt can accurately position the product to ensure the stability and consistency of the product during transportation.

FAQs

How long will it take to receive the product after placing the order?

The delivery time of a product usually depends on several factors, such as the number of orders, production process, logistics transportation time, etc. Before placing an order, we will confirm with you the delivery time of the product and meet your needs as much as possible.

Generally speaking, we will arrange production and delivery as soon as we receive your order. If the product is in sufficient stock, it can usually be shipped within 3-5 business days; if customized production is required, the delivery time will depend on your needs and the product’s production cycle. We will do our best to ensure that orders are delivered on time within the scheduled time, and in terms of logistics and transportation, we also provide full tracking and delivery services to ensure that you receive the products in a timely manner.

Please note that in some special circumstances, such as weather reasons, national holidays, etc., may affect logistics transportation times, we will promptly notify you and try our best to resolve the issue.

Is there an installation guide?

Our installation guides are designed to help customers better understand and install our pointed conveyors, ensure that the equipment works properly, and provide stable product delivery services.

Preparation before installation: including inspection of equipment, preparation of required tools and materials, etc.

Installation steps: including operation steps such as fixing the conveyor belt, installing the driving equipment, connecting the conveyor belt, etc.

Precautions: including safety operating specifications, equipment maintenance points, common fault handling, etc.

If you need more specific installation instructions or additional technical support, you can contact us in the following ways:

Customer service hotline: You can call our customer service hotline and our customer service staff will help and support you. You can find the contact details of the customer service hotline on our official website.

Online customer service: Our official website provides online customer service. You can contact our sales team through online customer service to get real-time answers and help.

Email: You can contact our sales team by sending an email, we will respond to your email as soon as possible and provide you with relevant technical support and solutions.