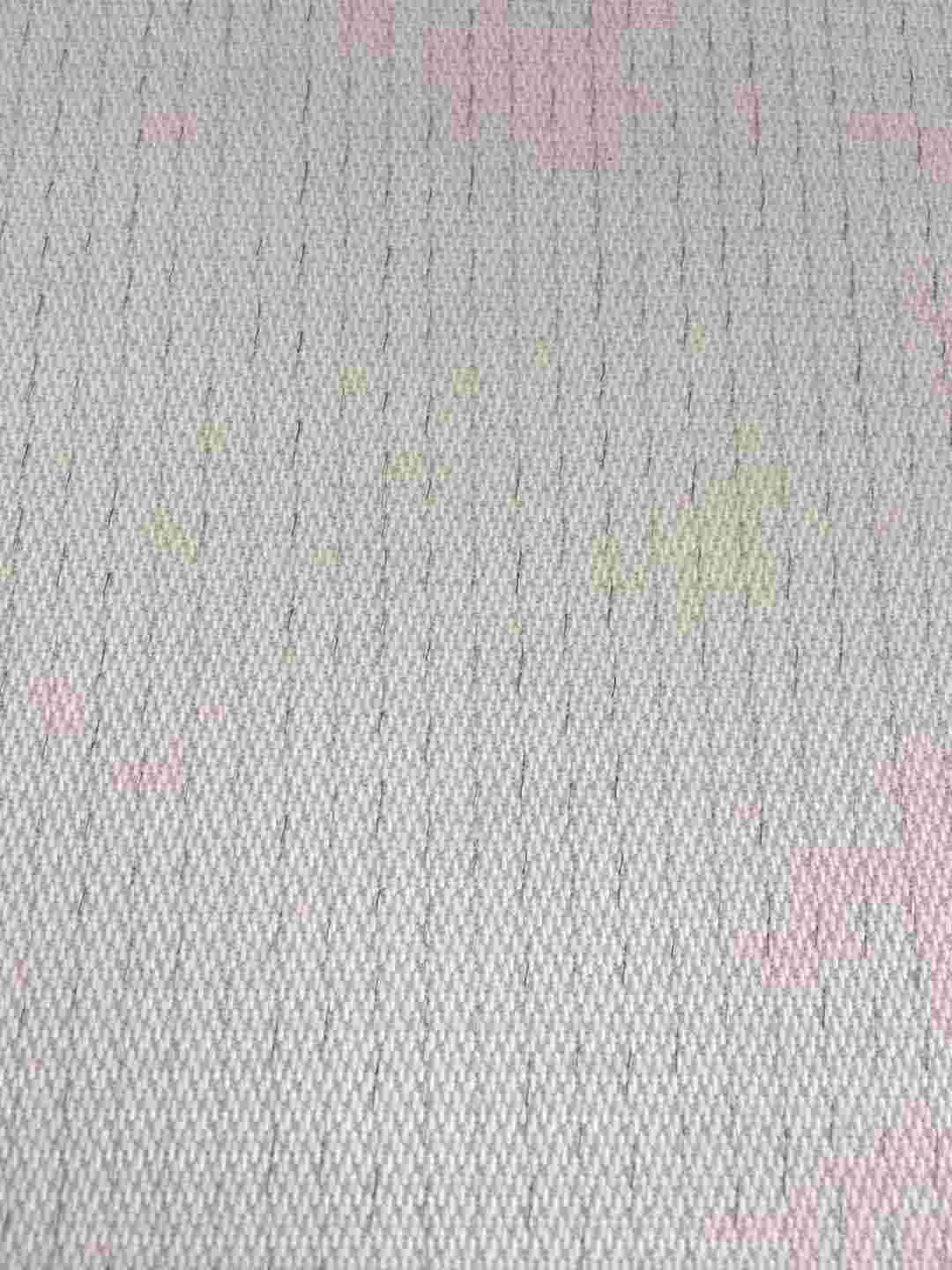

Product features:

High quality cotton yarn knitting: Made of high quality cotton yarn, it has high strength and wear resistance, and can adapt to different working environments and transportation conditions.

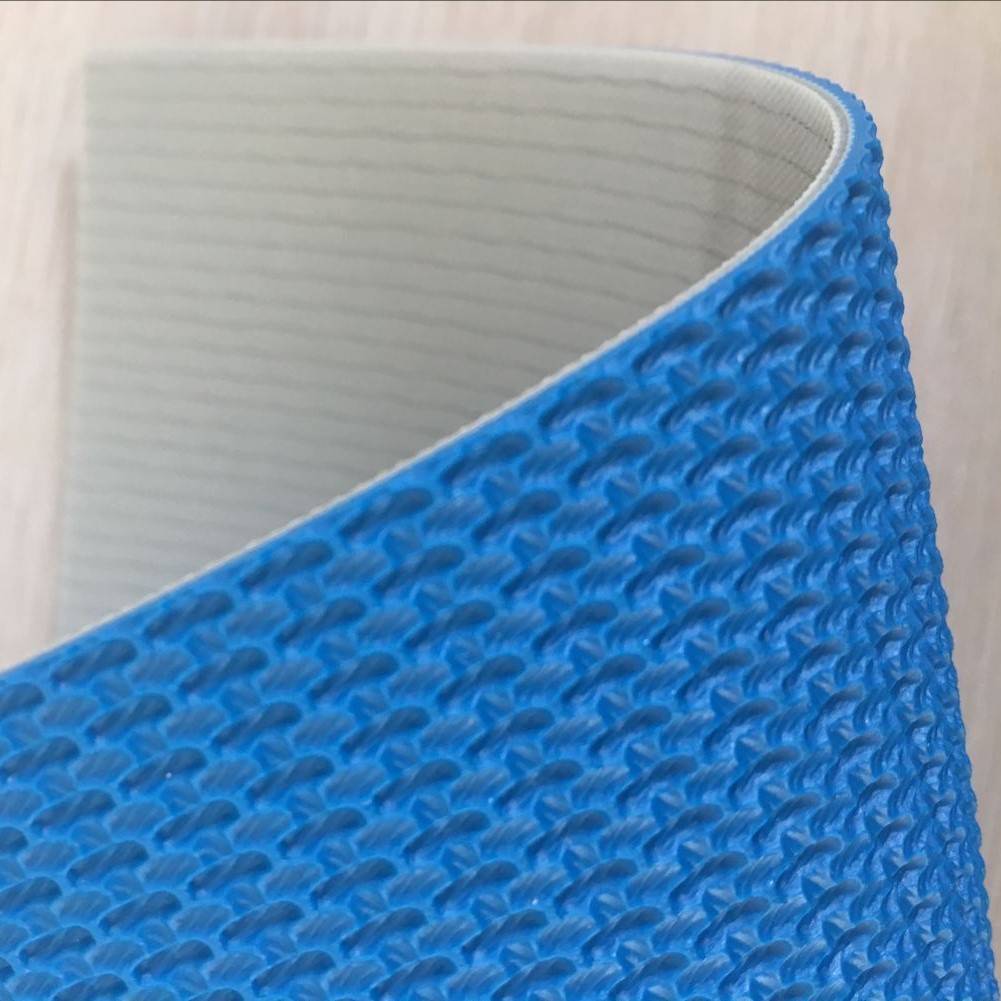

Seamless joint: A special seamless joint process is used to make the joint part of the conveyor belt flatter, firmer and more stable to avoid problems such as production line shutdown caused by wear or fracture of the joint part.

Pollution-free and odorless: Using non-toxic, odorless and non-polluting raw materials, it will not cause any pollution or impact on the conveyed materials, and is in line with international environmental standards.

Wear resistance, high temperature resistance and corrosion resistance: It has good wear resistance, high temperature resistance and corrosion resistance, and can maintain stable transportation effect and service life in harsh working environments.

Strong adhesiveness: The surface adhesiveness is strong, which can effectively prevent the conveyed materials from slipping and deviating, and maintain smooth operation.

Long service life: Manufactured using high-quality raw materials and advanced process technology, the service life is long, the cost and frequency of equipment maintenance are reduced, and production efficiency and economic efficiency are improved.

Product specifications:

The specifications and sizes of seamless woven cotton conveyor belts can be customized according to customer requirements and applications. Common specifications include width 100mm-2000mm and thickness 1.5mm-10mm.

Areas of application:

Seamless woven cotton conveyor belts are suitable for various industries and applications, such as food processing, logistics, packaging, textile printing and dyeing, etc., and can meet customer needs for efficient, stable and reliable transportation.

Product advantages:

Efficient and stable: The surface of the seamless woven cotton conveyor belt has strong surface adhesion, which can effectively prevent textile materials from slipping and deviating, maintain a stable conveying effect, and improve production efficiency.

Wear resistance: The materials used in the textile industry are usually fragile and easy to wear, while the seamless woven cotton conveyor belt is woven with high-quality cotton yarn, which has good wear resistance and can guarantee a long-term stable service life.

Pollution-free: The products produced by the textile industry have high environmental and health requirements, and the seamless woven cotton conveyor belt uses non-toxic, odorless and pollution-free raw materials, which will not cause any pollution or impact on textile materials and the environment.

High temperature resistance: The textile industry usually requires high temperature processing, and seamless woven cotton conveyor belts have good high temperature resistance, can operate stably in high temperature environments, and maintain high quality production efficiency.

Easy to clean: The seamless woven cotton conveyor belt has a smooth surface and seamless joints, is easy to clean, and can keep production lines in the textile industry clean and hygienic.

Maintenance recommendations:

Regular inspection: Check the conveyor belt regularly to check for wear, cracks, deformation, etc., and detect and deal with problems in a timely manner.

Cleaning and maintenance: Clean the surface of the conveyor belt regularly to prevent dust, debris and other pollutants from entering the conveyor belt and affecting the operating effect of the conveyor belt. Also, avoid using acidic and alkaline cleaners to avoid damaging the surface of the conveyor belt.

Avoid overloaded use: avoid overloaded use, exceeding the carrying capacity of the conveyor belt, so as not to cause problems such as fracture or deformation of the conveyor belt.

Avoid high temperature and strong acid and alkali environments: Avoid the conveyor belt from working for a long time in a high temperature or strong acid and alkali environment, so as not to cause problems such as aging and deformation of the conveyor belt.

Avoid excessive bending: Avoid excessive bending of the conveyor belt, so as not to cause problems such as damage or deformation of the conveyor belt.

Regular lubrication: For some areas that need lubrication, lubricate them regularly to ensure their normal operation.