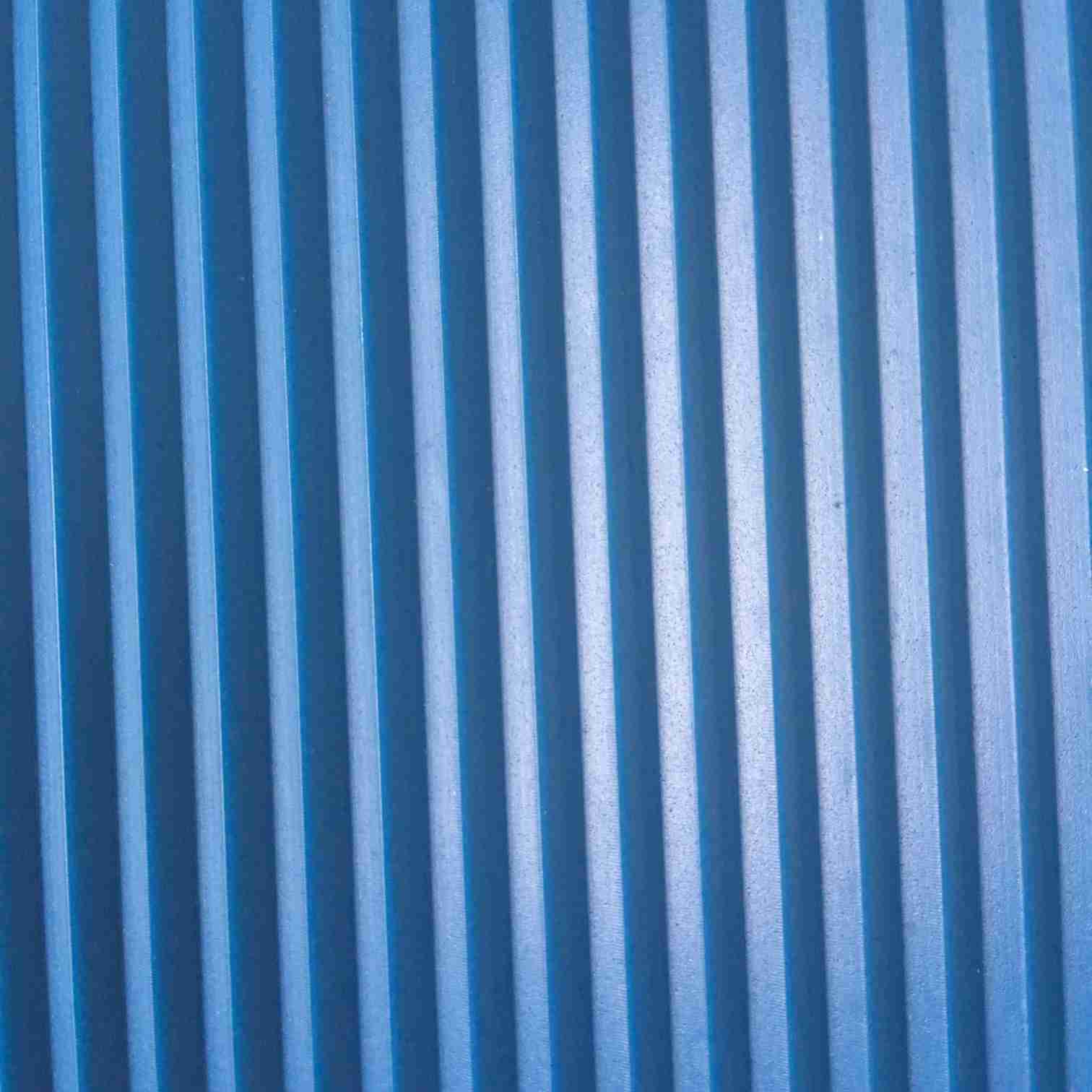

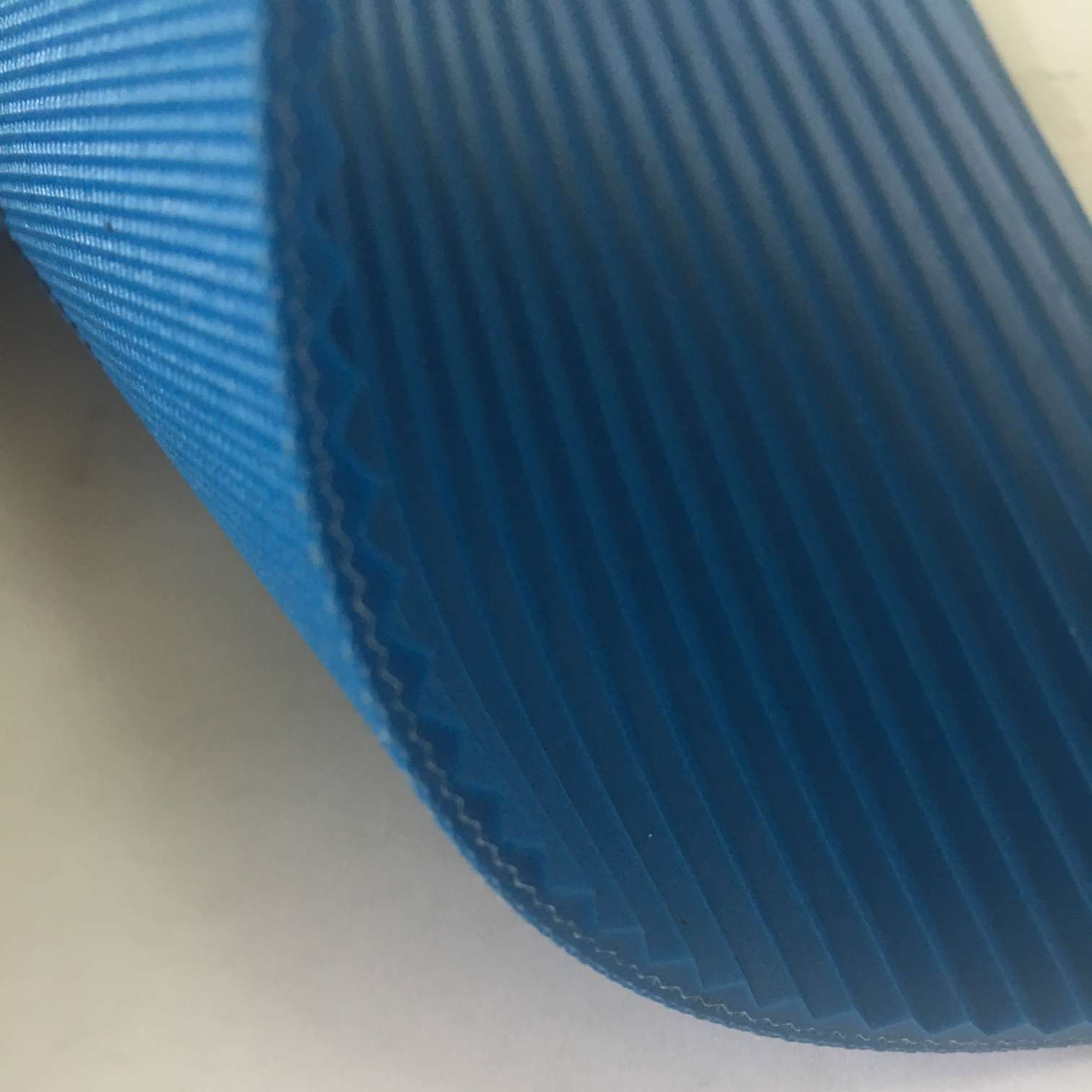

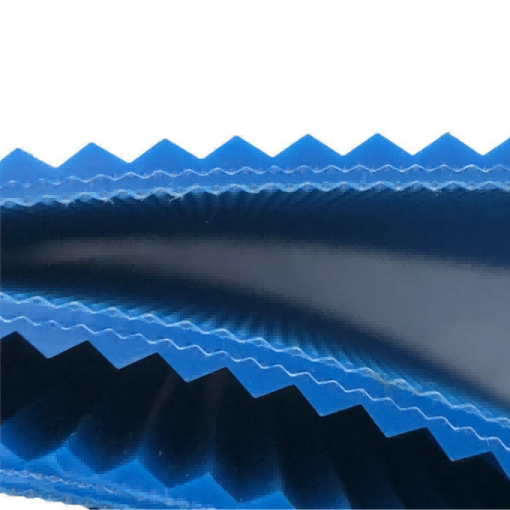

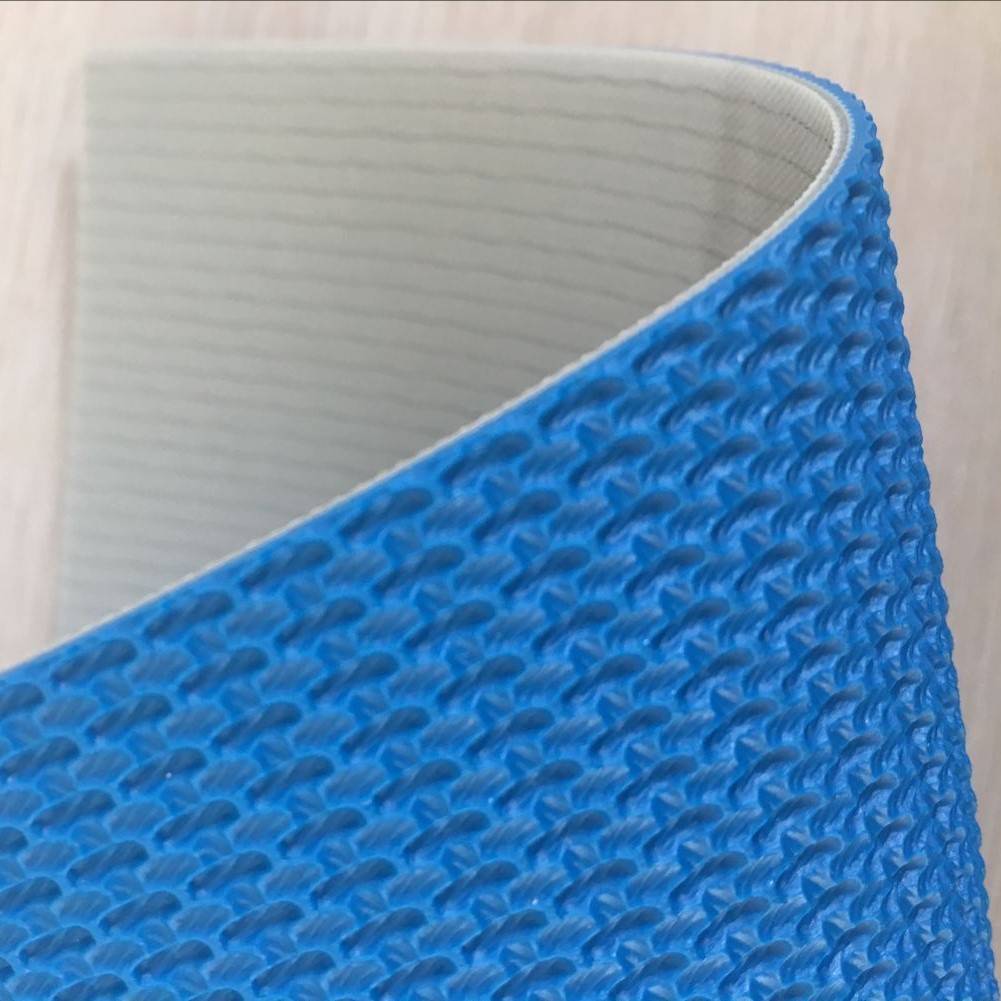

PVC small triangular pattern conveyor belt is a type of conveyor belt commonly used in the food industry. It is mainly made of PVC material and has the characteristics of anti-slip, wear resistance, corrosion resistance, etc. The surface is covered with a small triangular pattern, which can effectively increase friction, avoid sliding of conveyed materials, and ensure the stability and safety of the conveying process.

The conveyor belt is commonly used in the food processing and packaging industry, such as bread, pastries, cookies, fruits, vegetables, meat, etc. The surface pattern design can effectively prevent food from falling, rolling, accumulation, etc., avoid contamination and loss during transportation, and facilitate cleaning and maintenance.

Product advantages:

- Material and quality: PVC small triangular conveyor belt. The material meets food safety requirements and does not contain harmful substances. At the same time, the quality must be stable and reliable, with high carrying capacity and wear resistance.

- Size specifications: You can select the appropriate size specifications according to actual needs, including length, width, thickness, etc., to ensure compatibility with the conveying equipment.

- Pattern design: The small PVC triangle pattern meets actual needs and can provide stable friction and grip to ensure that items do not slide or fall during transportation.

- Safety performance: Shunsheng conveyor belt has good safety performance during use. It is not easy to break or slide, and can also effectively prevent safety issues such as static electricity and fire.

- Manufacturer’s reputation and after-sales service: As a well-known Chinese brand and a manufacturer of a certain scale, you can get better product quality and after-sales service guarantees, which is also conducive to future maintenance and updates.

Product usage precautions:

- Installation: Pay attention to the direction of the conveyor belt during installation. It must be installed in the direction of the arrow to ensure its normal use and operation.

- Maintenance: Clean and maintain the conveyor belt regularly to remove foreign objects and dirt to keep its surface clean and smooth, and prolong its service life.

- Load: Operation should be carried out in strict accordance with the specified load range during use to avoid overload use, causing damage or failure of the conveyor belt.

- Environment: Avoid using the conveyor belt in high temperature, humidity, corrosive environments, etc., so as not to affect its performance and lifespan.

- Use temperature: The use temperature of the PVC small triangle pattern conveyor belt should be within the range of -10℃ to +80℃. Exceeding this range may cause the conveyor belt to deform or fail.

- Maintenance: If the conveyor belt is damaged or faulty, it should be stopped for inspection and maintenance in a timely manner to avoid affecting production and use safety due to the fault.

- Storage: Direct sunlight and humidity should be avoided during storage to avoid affecting its quality and lifespan.

- Scope of use: PVC small triangular conveyor belts are suitable for conveying equipment in the food, medical, chemical, electronics, textile and other industries, and are not suitable for dangerous goods transportation equipment.

Handling details after product damage:

- Shutdown: Stop immediately, power off the conveying equipment, and stop the conveyor belt in a safe position.

- Inspection: Check the damage to the conveyor belt and determine the location and extent of the damage, including the length, width, thickness and pattern of the conveyor belt.

- Maintenance: Select the appropriate repair method according to the damage situation, such as replacing part or all of the conveyor belt, repairing or replacing the conveyor belt joints, etc.

- Testing: After maintenance is completed, testing and debugging should be carried out to ensure that the conveyor belt can operate and work normally.

- Maintenance: After the repair is completed, the maintenance of the conveyor belt should be strengthened, and regular inspection and maintenance should be carried out to ensure that the conveyor belt is in good condition of use.

It is important to note that seriously damaged conveyor belts, such as fractures, serious wear, etc., should be replaced promptly.

Tips for choosing a conveyor belt:

- Properties of conveying materials: Different conveying materials have different properties, such as particles, powders, liquids, pastes, etc., and the corresponding conveyor belt needs to be selected according to the nature of the conveying materials.

- Use of conveyor belts: Choose conveyor belts of different materials, structures and specifications according to different uses, such as transportation, processing, packaging, etc.

- Working environment: Consider the environment where the conveyor belt is located, such as temperature, humidity, corrosiveness, etc., and select a conveyor belt of suitable material and structure.

- Load requirements: According to the load requirements of the conveyed materials, select the appropriate conveyor belt type and specification to avoid overloaded use, causing the conveyor belt to wear or damage.

- Difficulty of maintenance: Choose a conveyor belt that is easy to maintain and clean so that it can be maintained and cleaned regularly to ensure the normal service life of the conveyor belt.

- Safety requirements: For situations where dangerous goods are transported, conveyor belts with safety properties such as fireproof, explosion-proof, and anti-static should be selected.