Introduction

PVC round stud pattern belts are a highly versatile and durable type of conveyor belt that is used in a wide range of industries, including food processing, packaging, and manufacturing. These belts are designed to provide excellent grip and traction, making them ideal for transporting materials on inclines and declines. In this brochure, we will explore the features, benefits, and applications of PVC round stud pattern belts in detail.

Features of PVC Round Stud Pattern Belts

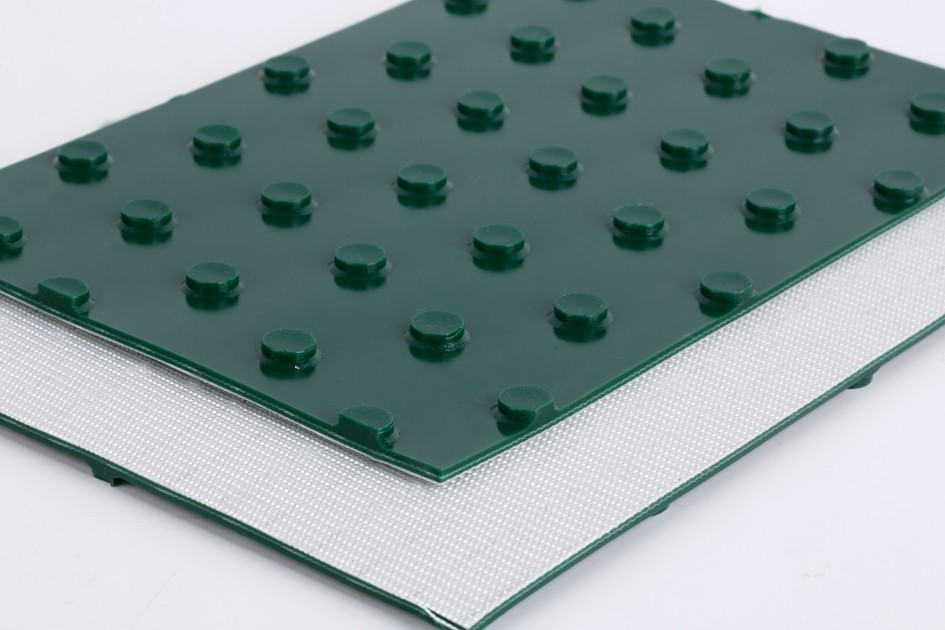

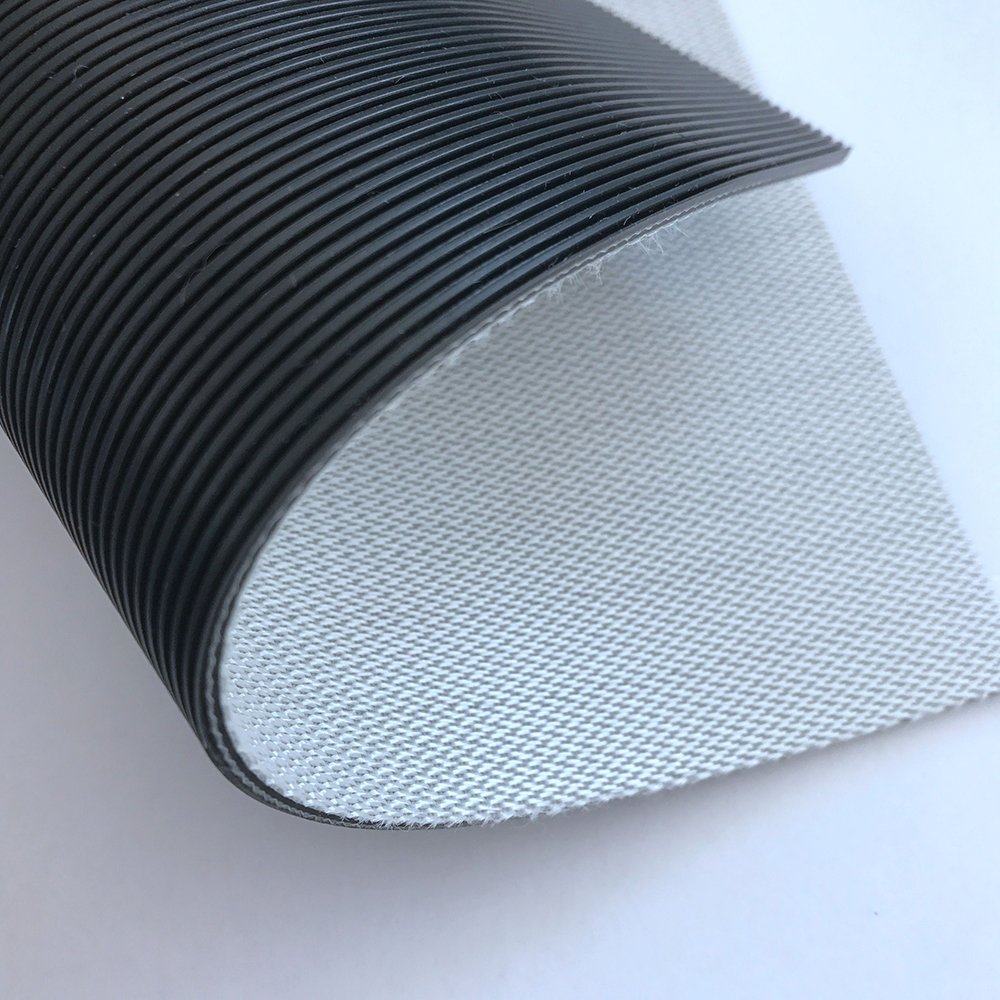

PVC round stud pattern belts are made from high-quality polyvinyl chloride (PVC) material, which is known for its durability, flexibility, and resistance to wear and tear. The belts feature a round stud pattern on their surface, which provides excellent grip and traction, even in wet or slippery conditions.

The studs on the belt are evenly spaced, which helps to prevent material build-up and ensures smooth and efficient operation. The belts are available in a range of sizes and configurations, making them suitable for various applications.

Benefits of PVC Round Stud Pattern Belts

PVC round stud pattern belts offer several benefits over other types of conveyor belts. These benefits include:

-

High Grip and Traction: The round stud pattern on the surface of the belt provides excellent grip and traction, even in wet or slippery conditions. This feature makes the belts ideal for transporting materials on inclines and declines.

-

Durability: PVC material is known for its durability and resistance to wear and tear. The belts are designed to withstand heavy loads and high impact, making them suitable for use in demanding applications.

-

Easy to Clean and Maintain: PVC round stud pattern belts are easy to clean and maintain, making them ideal for use in hygienic environments, such as in the food processing industry.

-

Customizable: The belts can be customized to meet specific requirements, such as size, width, and pattern, making them suitable for a wide range of applications.

Applications of PVC Round Stud Pattern Belts

PVC round stud pattern belts are used in a wide range of industries and applications, including:

-

Food Processing: PVC round stud pattern belts are commonly used in the food processing industry for transporting food products, such as fruits, vegetables, and meat. The belts are designed to meet FDA and USDA standards for food safety and hygiene.

-

Packaging: PVC round stud pattern belts are used in the packaging industry for transporting and sorting packages, boxes, and containers. The belts are designed to withstand heavy loads and high impact, making them suitable for use in packaging facilities.

-

Manufacturing: PVC round stud pattern belts are used in the manufacturing industry for transporting materials, such as metal parts, plastic components, and rubber products. The belts are designed to provide excellent grip and traction, making them ideal for use on inclines and declines.

-

Agriculture: PVC round stud pattern belts are used in the agriculture industry for transporting crops, such as grains, fruits, and vegetables. The belts are designed to withstand the harsh conditions of the agricultural environment, such as dust, dirt, and moisture.

PVC round stud pattern belts are highly customizable, which means that they can be tailored to meet specific requirements for size, width, pattern, and color. Here are some of the customization options available for PVC round stud pattern belts:

-

Size: PVC round stud pattern belts can be customized to any length and width, depending on the application requirements. The size of the belt can be specified according to the size of the product being transported or the dimensions of the conveyor system.

-

Pattern: The round stud pattern on the surface of the belt can be customized to meet specific requirements. The studs can be made larger or smaller, or the spacing between the studs can be adjusted to provide more or less grip as needed. Custom patterns can also be created to suit specific applications.

-

Color: PVC round stud pattern belts can be made in a variety of colors, depending on the application requirements. For example, belts used in the food processing industry may be made in white or light colors to meet hygiene standards.

-

Thickness: PVC round stud pattern belts can be customized to different thicknesses, depending on the application requirements. Thicker belts can withstand heavier loads and impact, while thinner belts are more flexible and suitable for smaller products.

-

Material: While PVC is the most commonly used material for round stud pattern belts, other materials can be used as well. For example, thermoplastic elastomers (TPE) and polyurethane (PU) can be used for applications that require higher resistance to oils and chemicals.

-

Accessories: PVC round stud pattern belts can be customized with various accessories, such as cleats, sidewalls, and tracking guides. These accessories can be added to the belt to provide additional grip and stability during transportation.

Conclusion

PVC round stud pattern belts are a highly versatile and durable type of conveyor belt that is used in a wide range of industries and applications. These belts offer several benefits, including high grip and traction, durability, easy maintenance, and customizability. Whether you are in the food processing, packaging, manufacturing, or agriculture industry, PVC round stud pattern belts are an excellent choice for transporting materials efficiently and reliably.