Product features:

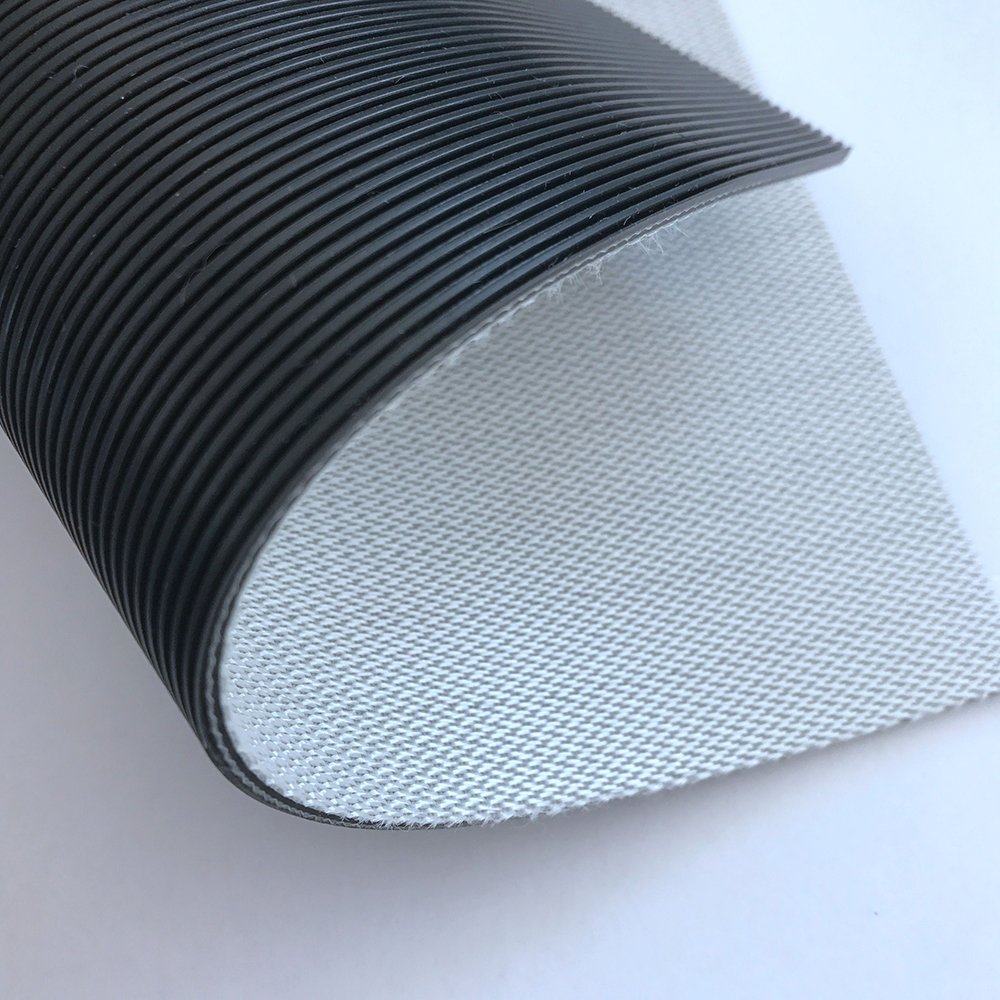

High-quality PVC material: Using high-quality PVC material, it has the characteristics of smooth surface, wear resistance, corrosion resistance, and not easy to deform, and can adapt to different working environments and transportation conditions.

Precision processing: Using advanced production technology and equipment, it is precision processed, and has high accuracy and stability to ensure the smooth operation of the conveyor belt.

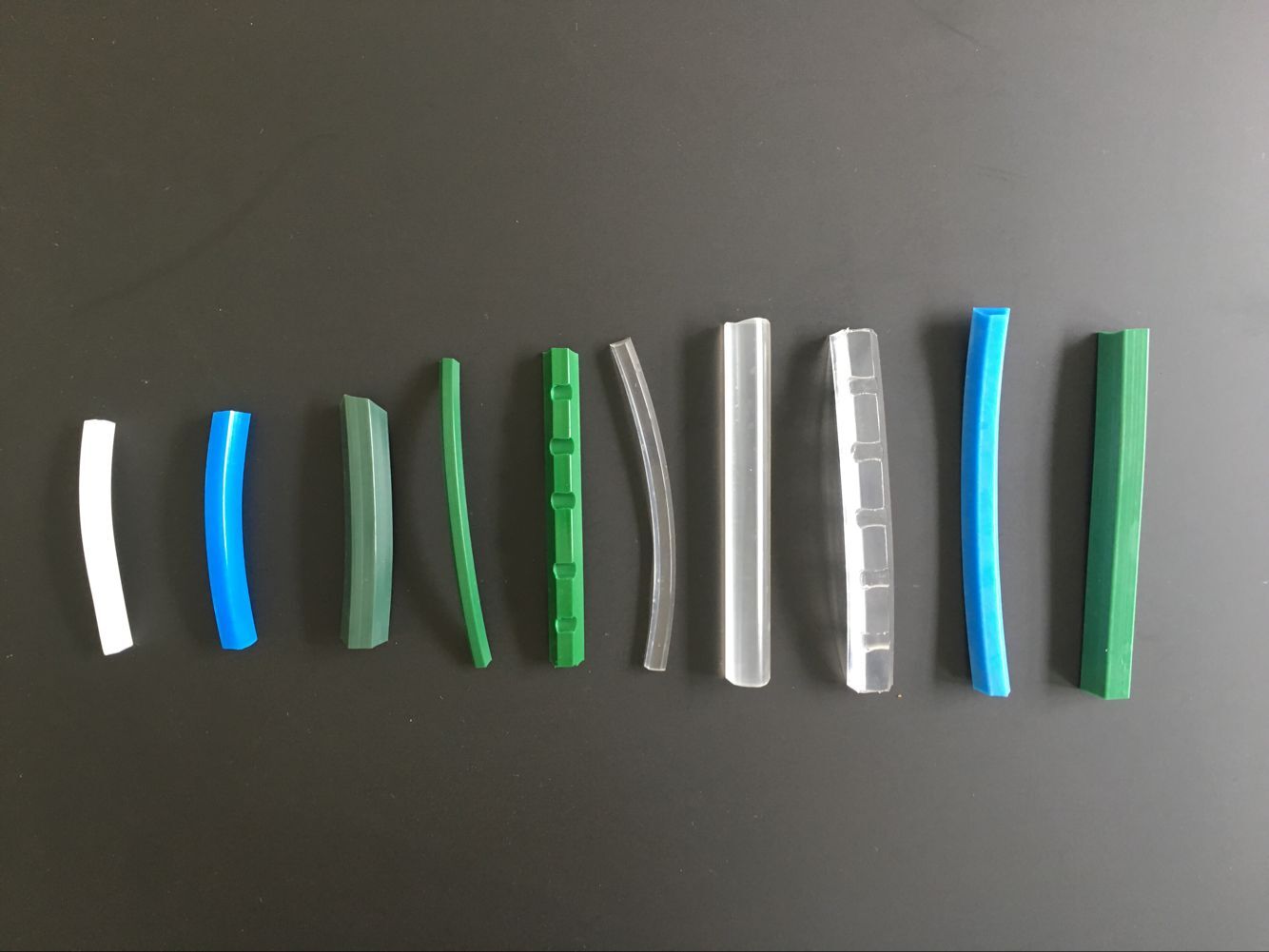

Multiple specifications and models: PVC rails and profiles of various specifications are provided to meet the conveying requirements of different occasions and needs.

Easy to install: PVC rails and profiles are easy to install, require no expertise, and require only simple tools to complete installation, reducing installation costs and time.

Easy to maintain: PVC rails and profiles have a smooth surface, are not prone to dust accumulation, are easy to clean, and maintenance costs are low.

Product application:

PVC rails and profiles are widely used in various conveyor belt systems and can provide efficient and stable conveying solutions. It is mainly used in logistics, packaging, food processing, pharmaceuticals, printing and other industries and fields. For example, it can be used for airport baggage conveyors, courier sorting lines, packaging production lines, food processing production lines, etc.

Product Type:

Straight rails and profiles: Straight rails and profiles are the most common type. They are usually used for linear transportation and the support and guidance of conveyor belts, and have high accuracy and stability.

V-rails and profiles: V-shaped guides and profiles are generally used to guide and support conveyors. They are particularly suitable for inclined transportation and inclined transportation, which can ensure the smooth operation of the conveyor belt.

U-shaped guides and profiles: U-shaped guides and profiles are commonly used to support and guide conveyors, especially when the conveyor belt needs to be bent and turned at a certain angle during movement.

Wing rails and profiles: Wing rails and profiles are commonly used to support and guide conveyors. They have high carrying capacity and stability, and are suitable for heavy loads and high-speed motion.

Toothed rails and profiles: Toothed guides and profiles are commonly used for the positioning and guidance of conveyor belts. They have high accuracy and stability, and are suitable for applications requiring high-precision transportation and positioning.

Functions of PVC Guide and Profiles in Conveyor Belts

PVC Guide and Profiles serve as multifunctional components within conveyor systems, offering a wide array of benefits that contribute to the efficiency and reliability of material handling processes. Let’s delve into these functions in detail.

Tracking and Alignment

Precise Tracking: PVC Guide and Profiles play a crucial role in guiding conveyor belts along the desired path, preventing off-center or misaligned movements.

Enhanced Belt Alignment: These profiles help maintain proper belt alignment, reducing the risk of damage and belt wear caused by misalignment.

Containment and Spillage Prevention

Material Containment: PVC Guide and Profiles effectively contain bulk materials and prevent spillage, ensuring that materials are efficiently transported without wastage.

Product Separation: They aid in the separation of products on conveyor belts, preventing unwanted contact and preserving product integrity.

Load Distribution

Even Load Distribution: PVC Guide and Profiles help evenly distribute the load across the conveyor belt, reducing stress on specific sections and prolonging belt life.

Protection against Impact: They act as a buffer, absorbing impact and reducing the risk of damage to both the conveyor belt and conveyed materials.

Noise Reduction

Noise Dampening: PVC Guide and Profiles contribute to a quieter operating environment by minimizing the noise generated by the conveyor belt

Material Handling Optimization

Customized Solutions: The versatility of PVC Guide and Profiles allows for customized solutions tailored to the specific needs of various industries and conveyor systems.

Enhanced Efficiency: Their role in load distribution and containment ensures efficient material handling and product flow, reducing bottlenecks and enhancing overall productivity.

With a clear understanding of their functions, let’s explore the numerous advantages that PVC Guide and Profiles offer to conveyor belt systems.

Advantages of PVC Guide and Profiles for Conveyor Belts

PVC Guide and Profiles are instrumental in optimizing conveyor belt performance, offering a multitude of advantages that can positively impact various industries. These advantages encompass improved efficiency, reduced maintenance costs, and enhanced safety.

Improved Conveyor Belt Efficiency

Enhanced Tracking: PVC Guide and Profiles help maintain precise belt tracking, reducing the risk of belt misalignment and subsequent downtime.

Spillage Prevention: By containing materials effectively, these profiles minimize spillage, ensuring that conveyed materials reach their destination without waste.

Reduced Maintenance Costs

Extended Belt Life: Even load distribution and impact absorption provided by PVC Guide and Profiles lead to reduced wear and tear on conveyor belts, prolonging their lifespan.

Less Downtime: Precise tracking and alignment mean less downtime for maintenance and repairs, resulting in increased operational efficiency.

Enhanced Safety

Improved Belt Alignment: Proper belt alignment facilitated by these profiles reduces the risk of accidents and damage to conveyor systems.

Product Integrity: PVC Guide and Profiles aid in product separation and containment, preserving the integrity of conveyed materials.

Customization and Adaptability

Tailored Solutions: The availability of various profiles and configurations allows for customized solutions, ensuring that PVC Guide and Profiles meet the specific requirements of different industries.

Compatibility: These profiles are compatible with a wide range of conveyor belt types, making them versatile and adaptable to various conveyor systems.

With a thorough understanding of their advantages, it’s essential to consider how to select the right PVC Guide and Profiles for your specific conveyor belt needs.

Choosing the Ideal PVC Guide and Profiles for Conveyor Belts

Selecting the right PVC Guide and Profiles is crucial for optimizing conveyor belt performance. To make an informed choice, consider the following key factors:

Conveyor Belt Type

Determine the type and design of your conveyor belt, as well as the materials it will be handling. This information will guide you in selecting the most suitable PVC Guide and Profiles.

Profile Dimensions

Consider the dimensions of the profiles, including height, width, and shape, to ensure they align with your conveyor system’s requirements.

Material Compatibility

Verify that the PVC Guide and Profiles are compatible with the materials being conveyed, especially in cases where the conveyed materials have unique characteristics or are chemically reactive.

Customization Options

Check if the manufacturer offers customization options, allowing you to tailor the profiles to your specific conveyor system.

Installation and Maintenance

Evaluate the ease of installation and maintenance of the PVC Guide and Profiles to ensure minimal disruption to your conveyor system’s operations.

With these considerations in mind, you can confidently select PVC Guide and Profiles that align with your conveyor belt requirements and operational goals.

Maintenance and Care of PVC Guide and Profiles

Proper maintenance and care of PVC Guide and Profiles are essential to ensure their longevity and continued performance. Here are some best practices to follow:

Regular Inspection

Conduct routine inspections to check for signs of wear, damage, or misalignment in the PVC Guide and Profiles. Address any issues promptly to prevent further damage.

Cleaning

Implement a regular cleaning schedule to remove any accumulated debris, dust, or contaminants from the profiles. Use appropriate cleaning agents to maintain hygiene.

Lubrication

If applicable, ensure that any moving parts of the conveyor system are adequately lubricated to reduce friction and wear on the PVC Guide and Profiles.

Employee Training

Train your personnel in conveyor belt maintenance and safety protocols, including the care of PVC Guide and Profiles, to minimize the risk of accidents and ensure the longevity of your equipment.

Product selection tips:

Consider the shape and size of the conveyor belt: Conveyors of different shapes and sizes require different types of rails and profiles. For example, straight rails and profiles are suitable for linear conveyors, while U-rails and profiles are for conveyor belts that require bending or turning.

Consider the weight and size of the items to be transported: The weight and size of the transported items will affect the load carrying capacity of the rails and profiles required. For heavier or larger items, rails and profiles with higher carrying capacity should be selected.

Consider conveying speed: Conveying speed also has an effect on the required rails and profiles. For higher conveying speeds, guide rails and profiles with higher accuracy and stability should be selected to ensure the smooth operation of the conveyor belt.

Consider the conveying distance: The conveying distance will affect the length and connection method of the rails and profiles required. For longer conveying distances, guide rails and profiles with better connectivity and stability should be selected.

Consider environmental factors: Environmental factors, such as temperature, humidity, corrosivity, etc., also need to be considered when selecting rails and profiles. For example, for conveyor belts that need to operate in a humid environment, guide rails and profiles with good corrosion resistance should be selected.