Production process and process:

Preparation of raw materials: Use food-grade PVC materials, fillers, additives and other raw materials to mix and mix.

Extrusion molding: The mixed raw materials are placed in an extruder and extruded at high temperature to form a long conveyor belt.

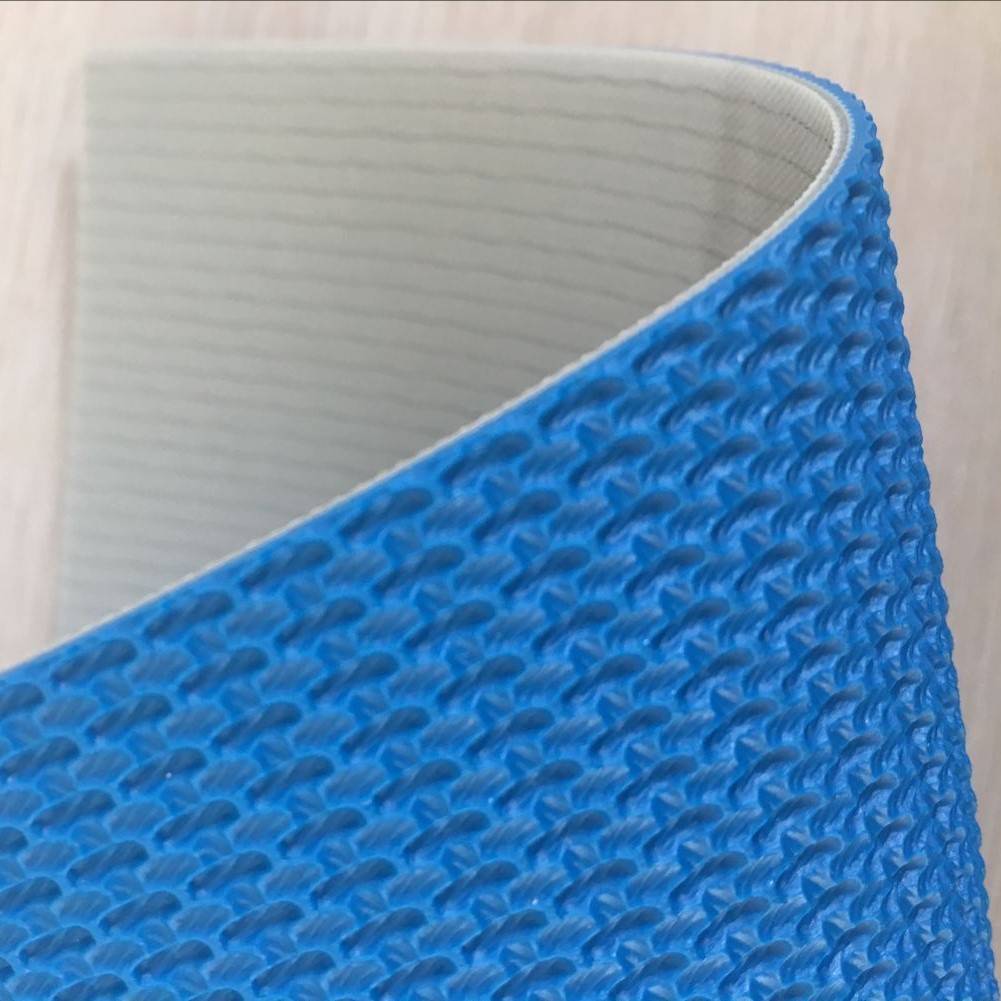

Surface treatment: The surface of the conveyor belt is treated to increase friction and grip, and improve the stability of the material.

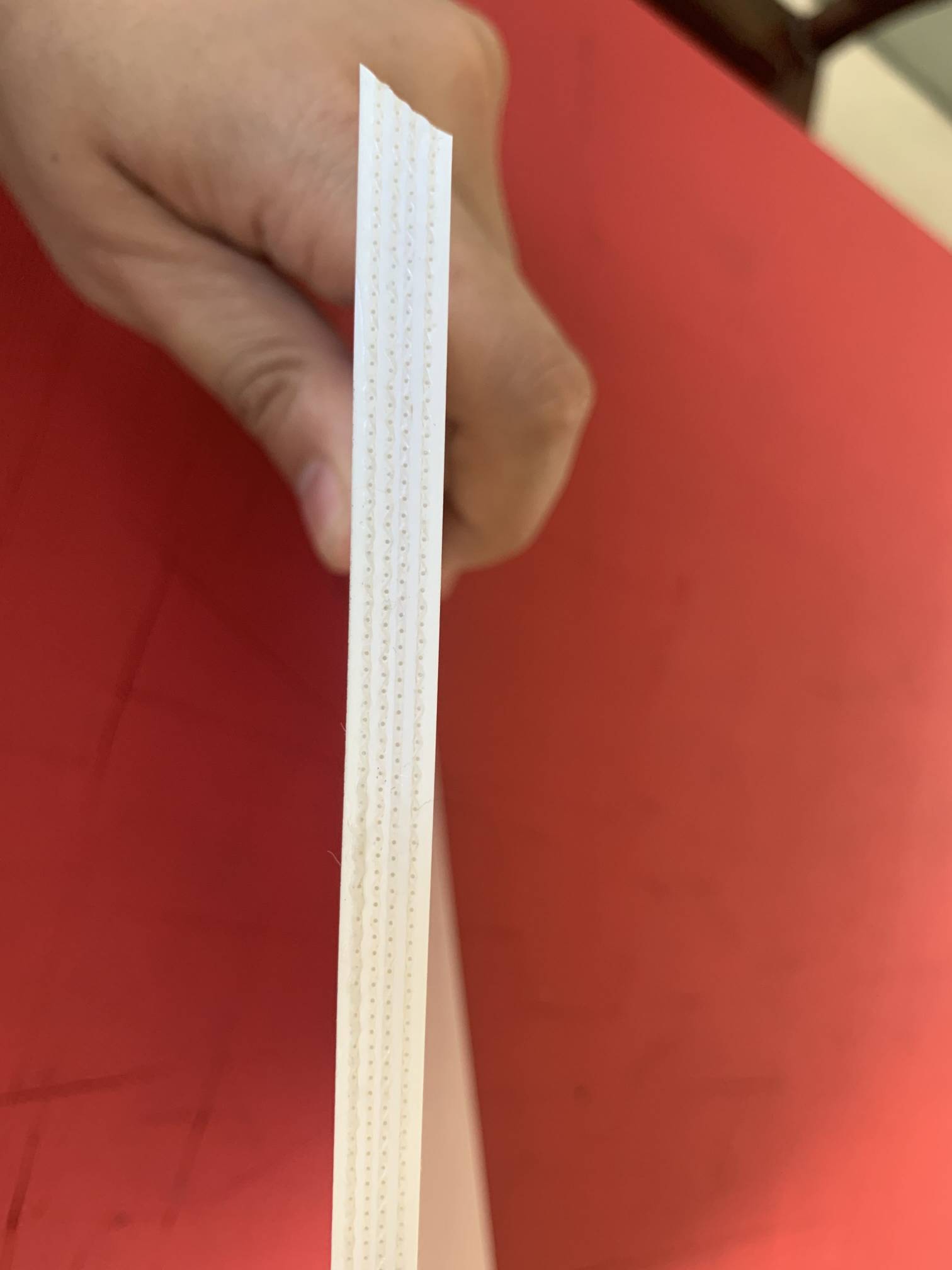

Cutting, drilling, welding and other processes: According to customer needs, conveyor belts are cut, perforated, welded to meet different usage needs.

Packaging: The finished conveyor belt is packaged to ensure the safety and hygiene requirements of transportation and storage.

Quality inspection:

The quality inspection process of PVC food grade cpneling belt for suger industry is carried out in strict accordance with international food safety standards, including raw material inspection, production process monitoring, finished product inspection, etc. Through the inspection of raw materials, production processes and finished products, the quality and safety of the conveyor belt is guaranteed.

Packaging:

PVC food grade conveyor belts are packaged with environmentally friendly materials and packaged according to international standards to ensure that the conveyor belt is not damaged and contaminated during transportation and storage.

After-sales service:

PVC food grade conveyor belts provide comprehensive technical support and services in after-sales service, including pre-sales consulting, in-sales guidance and after-sales service. At the same time, we provide a complete after-sales service system, respond to customer needs and problems in a timely manner, and ensure customer satisfaction and trust.

The service life of PVC food grade cpneling belts for suger industry is affected by many factors, such as the usage environment, load, frequency of use, etc., so it is impossible to give the exact length of service life. Generally speaking, proper use and maintenance of PVC food grade conveyor belts used in the sugar industry can extend their useful life.

Avoid situations such as overload, reverse operation, and scratching of sharp objects during use. At the same time, clean and lubricate regularly, and replace seriously worn areas in a timely manner.

Choosing Shunsheng’s PVC food grade cpneling belt for suger industry has characteristics such as wear resistance, corrosion resistance and high temperature resistance, which can extend the service life.

When storing the conveyor belt, avoid conditions such as direct sunlight, humidity and high temperatures, so as not to affect the quality and service life of the conveyor belt.

Check the wear of the conveyor belt regularly, replace parts with severe wear in a timely manner, and avoid damage and replacement of the conveyor belt due to excessive wear and tear.

Conveyor belt wear inspection method

Direct observation: Directly observe the surface of the conveyor belt to check for defects such as wear, cracks, cracks and cracks, foreign matter, stains, etc.

Touch inspection: Touch the surface of the conveyor belt with your hands to see if there are any bulges, depressions, hardening and deformation, as well as any odors or foreign matter.

Measurement inspection: Use professional measuring tools to measure the width, thickness, length, etc. of the conveyor belt to check whether it meets the requirements of the standard.

Vibration inspection: Use equipment such as a vibration detector to check the vibration of the conveyor belt to determine whether there are problems such as wear and friction.

Wear marks: After the conveyor belt is in normal use, it can be marked on the conveyor belt so that wear can be checked. For example, mark a line at one end of a conveyor belt and check every once in a while to see if the position of this line has changed.

Remediation method

Replace the conveyor belt: If the conveyor belt is too worn, cannot be repaired, or has exceeded its useful life, the conveyor belt needs to be replaced.

Patch repair: For conveyors that are partially worn, patch repair methods can be used. First, clean the wear area and make sure the surface is clean and dust-free. Then, use a special patch material, apply it to the worn area, fix and flatten it according to the requirements of the instructions, and wait for it to harden.

Welding repair: For situations where the worn parts of the conveyor belt are large or have cracks, fractures, etc., welding repair methods can be used. The worn part is first removed, then the welding material is welded to the worn area using special welding equipment, and treatment such as pressing, leveling and polishing is carried out to flatten the surface of the original conveyor belt.

Shunsheng PVC food grade conveyor belt is a safe, hygienic and efficient conveyor belt product. It has good quality and after-sales service guarantees, and can meet transportation needs in the candy production process.