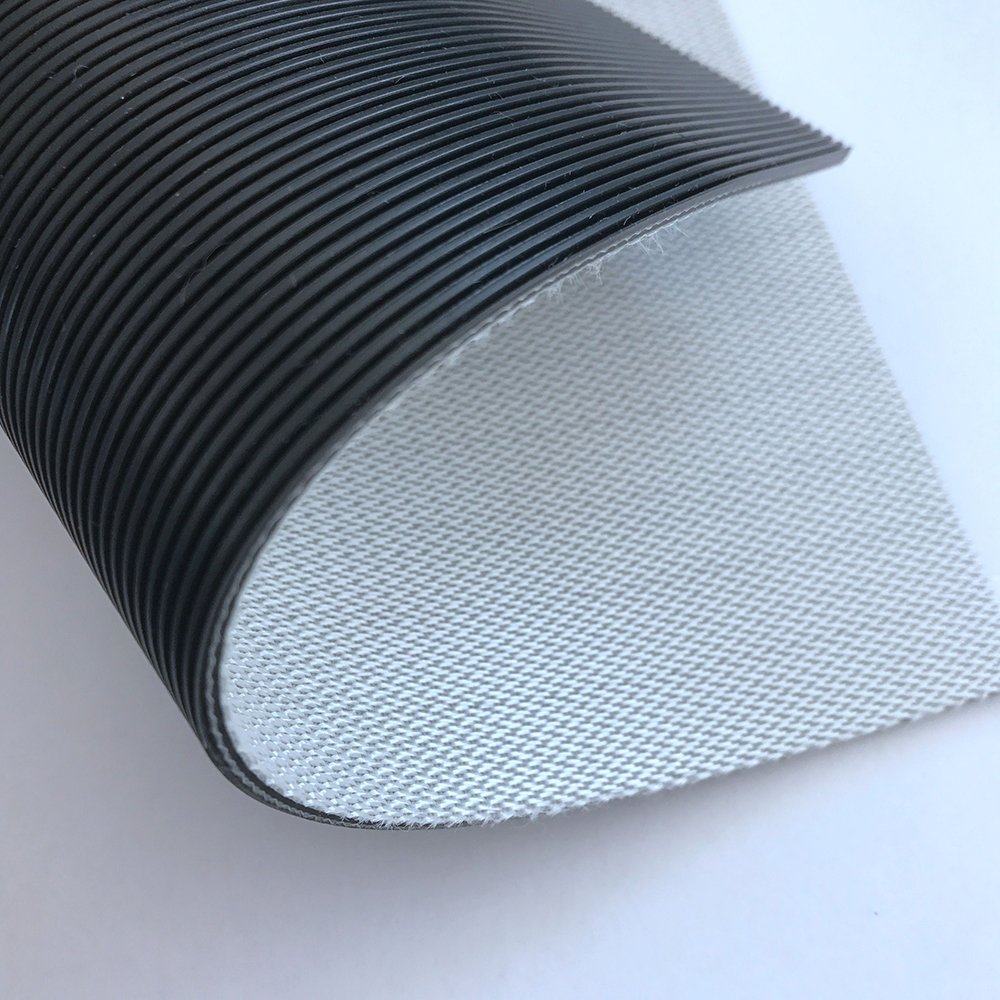

PVC foil is an important component in the conveyor belt system. It can effectively protect the conveyor belt and conveyed items, reduce friction and wear, and extend the life of the conveyor belt. Using advanced production processes, our PVC foils have high strength, high flexibility and stable dimensions. Additionally, we also supply various types of PVC foils to meet the needs of different industries and applications.

In addition to PVC foils, we also supply various types of PVC accessories, including splints, buckles, connectors, brackets, etc. These accessories can be used with PVC foils to help you build a complete conveyor belt system and ensure its proper operation.

Product features:

- Using high-quality PVC material, it has the properties of wear resistance, corrosion resistance, high temperature resistance and low temperature resistance;

- It has high strength, high flexibility and stable size;

- It can meet the needs of different industries and applications;

- Helping you build a complete conveyor belt system and keep it running properly.

Areas of application:

The product is suitable for all types of conveyor belt systems, including logistics, packaging, food, medical, chemical and mining industries.

Things to note:

Before installation, be sure to check whether the size and model of the PVC foil and accessories match your conveyor belt system;

During installation and use, please follow the corresponding installation and maintenance guide to ensure its normal operation;

If you need to replace the PVC foil and accessories, please follow the appropriate replacement process and use the appropriate tools and safety measures.

What is the expected service life of PVC foils and fittings?

Usage environment: The usage environment of PVC foils and accessories may have an impact on their longevity. Exposure to UV rays, for example, may cause PVC foil to age, thereby reducing its useful life. Also, exposure to chemicals and solvents may affect the longevity of PVC foils and fittings.

Working conditions: The working conditions of PVC foils and fittings may also affect their longevity. For example, if PVC foils and fittings operate at high or low temperatures, or at high speeds and loads, their longevity may be affected.

Maintenance and care: Proper maintenance and care can extend the life of PVC foils and fittings. For example, regular cleaning and lubrication can reduce friction and wear, thereby extending its life.

What are some common maintenance practices for PVC foils and fittings?

Regular cleaning: Regular cleaning of PVC foil and fittings can reduce friction and wear and extend their service life. Clean the PVC foil and fittings thoroughly by gently wiping them clean with detergent and water.

Lubrication: Using appropriate lubricants or lubricants can reduce friction and wear on PVC foils and fittings. Lubrication should be done regularly and with proper lubricant to ensure proper operation.

Check for wear: Regularly check the wear of PVC foil and pipe fittings, and replace worn or damaged parts in a timely manner to prevent further damage.

Protection from sunlight: PVC foil and pipe fittings are susceptible to sunlight, and prolonged exposure to sunlight may cause aging, deformation, and breakage. Therefore, PVC foils and fittings should be placed away from direct sunlight.

Avoid being affected by chemicals and solvents: Many chemicals and solvents may damage PVC foils and fittings. Therefore, PVC foils and fittings should be avoided from coming into contact with these substances.

Regular inspection: Regularly check the installation and connection of PVC foil and pipe fittings to ensure their normal operation. If any issues are found, they should be promptly repaired or replaced.