Product features:

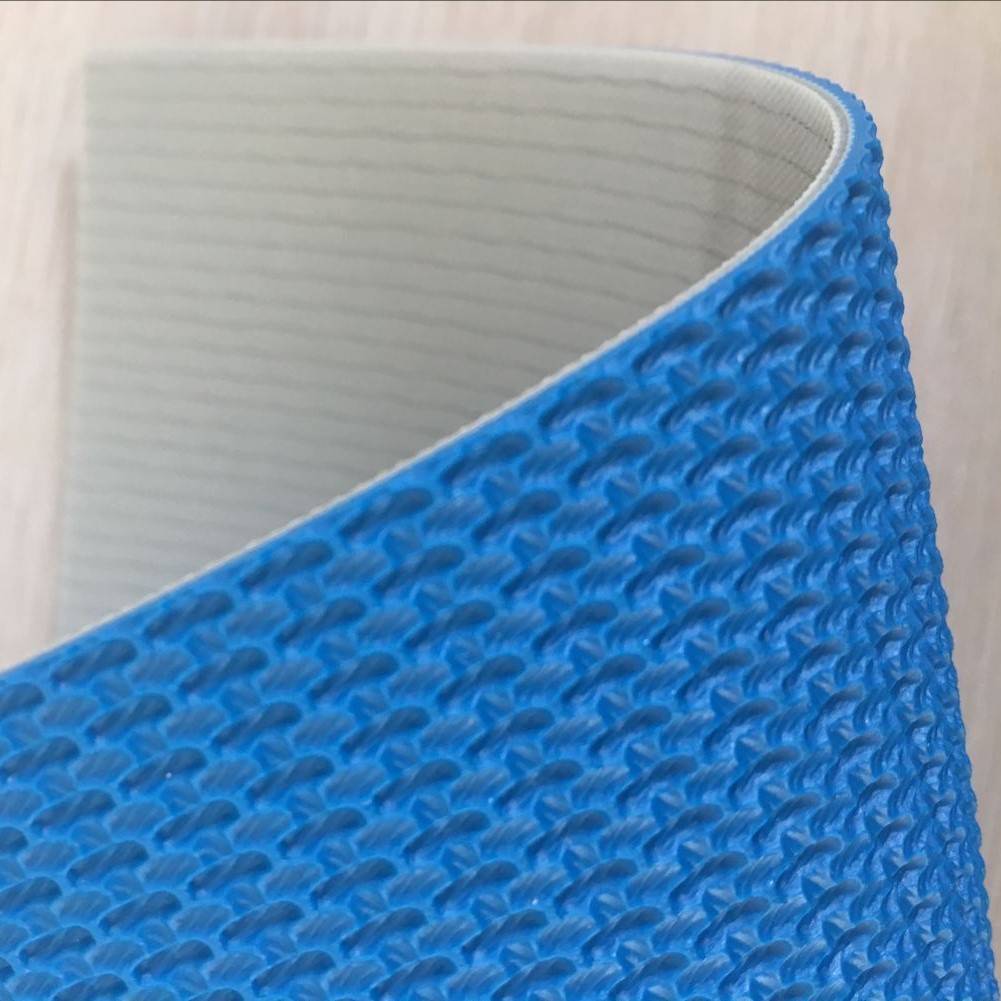

- Material: PVC material, with good wear resistance, corrosion resistance and high temperature resistance, can be adapted to different working environments.

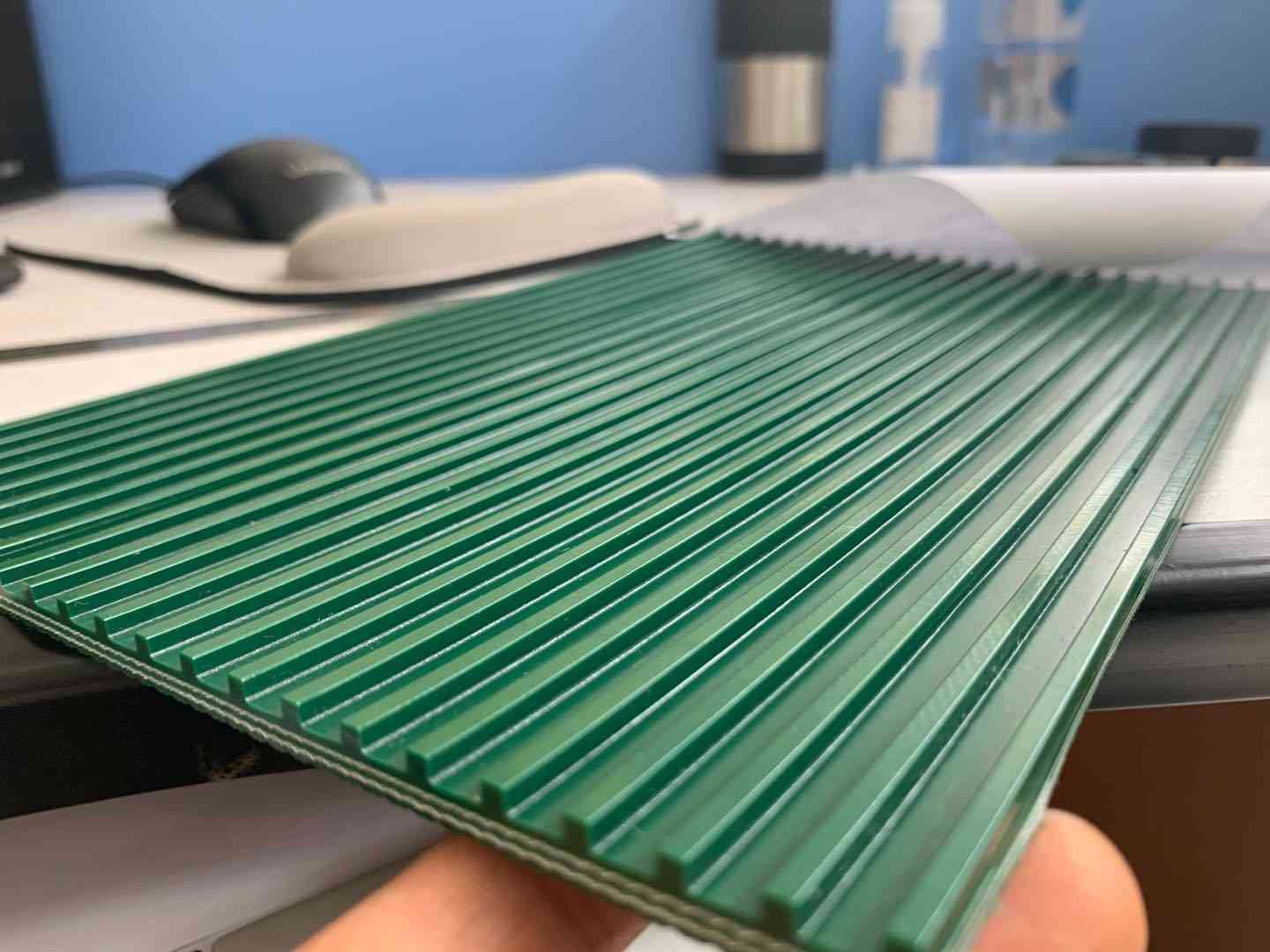

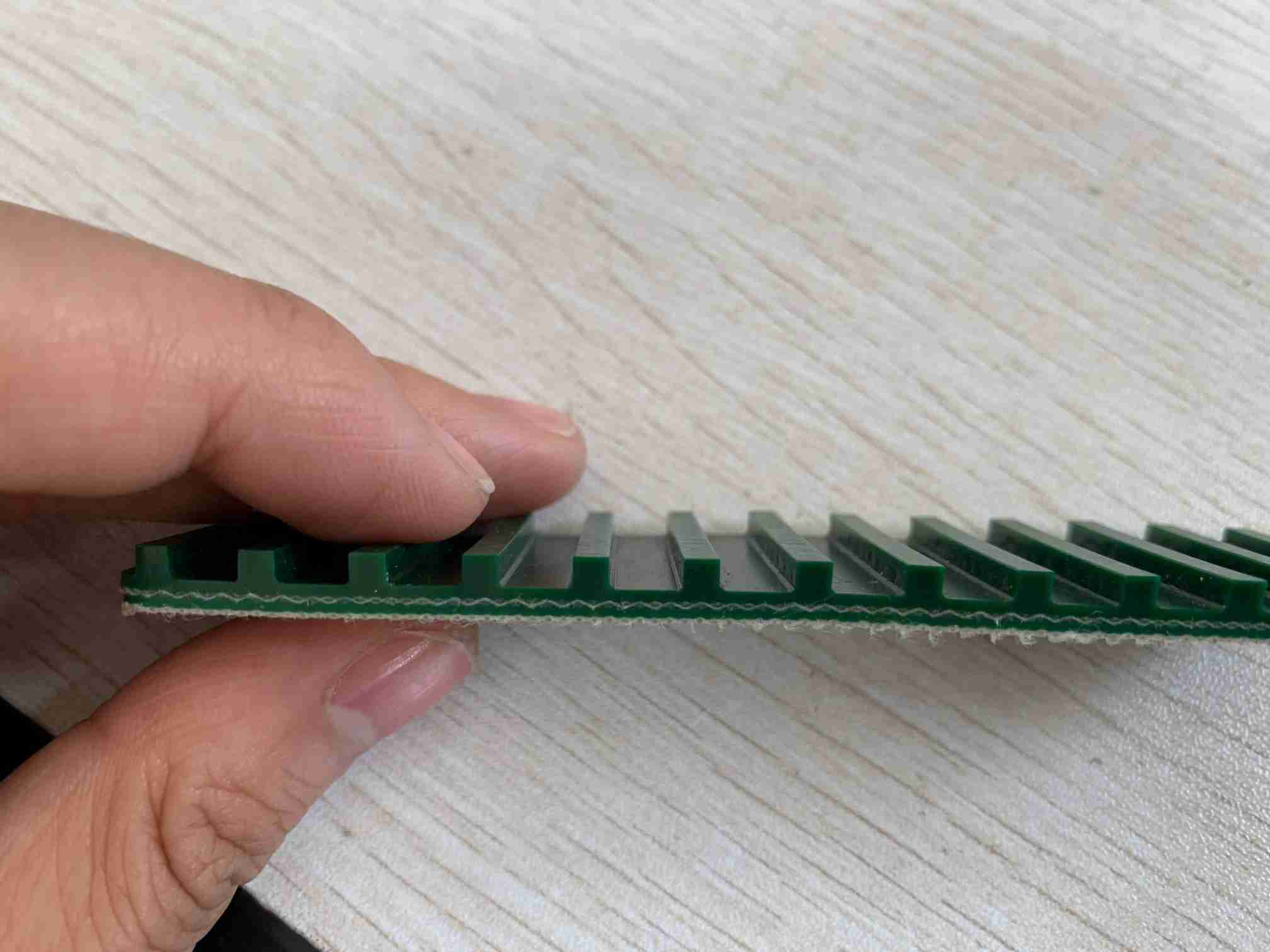

- Pattern design: The surface design has horizontal stripes and patterns, which can effectively increase friction and adsorption to ensure stable transportation of materials.

- Color options: The surface color of the product can be customized according to your needs to meet the needs of different industries and application scenarios.

- Stability: The product has excellent stability and durability, can work stably for a long time, reducing the number of repairs and replacements.

- Scope of application: PVC transverse ribbed conveyor belts are suitable for transporting various materials, such as food, electronics, chemical, machinery and other industries.

- Easy installation: The installation and maintenance of the product is simple and convenient.

Product specifications:

- Thickness: 1.5mm, 2.0mm, 3.0mm, etc.

- Width: from 100mm to 2000mm.

- Length: The standard length is 50 meters/roll and can also be customized according to your needs.

Common misconceptions:

PVC transverse ribbed conveyor belts can only be used to transport lightweight materials:

In fact, PVC horizontal ribbed conveyor belts can be used to transport all kinds of materials, including heavy materials, such as ore, coal, etc. Its surface is designed with transverse ridges and patterns, which can effectively increase friction and adsorption to ensure stable transportation of materials.

The service life of PVC transverse ribbed conveyor belts is very short:

In fact, PVC transverse ribbed conveyor belts have excellent wear resistance and durability, can work stably for a long time, and reduce the number of repairs and replacements.

PVC transverse ribbed conveyor belts can only be used in indoor environments:

PVC transverse corrugated conveyor belts can be applied to indoor and outdoor environments because the material is wear-resistant, corrosion-resistant and heat-resistant, and can adapt to different working environments.

The installation and maintenance of PVC transverse ribbed conveyor belts is complicated:

In fact, the installation and maintenance of PVC transverse conveyor belts is very simple and convenient, and can be customized according to customer needs.

The price of PVC transverse ribbed conveyor belt is very high:

The price of PVC corrugated conveyor belts is not high compared to other types of conveyor belts, and because of their stability and durability, they can reduce the number of repairs and replacements, and in the long run, their total cost will also be lower.

What is the relationship between the thickness of the conveyor belt and the weight of the material?

The thickness of the conveyor belt is closely related to the weight of the material. The conveyor belt needs to bear the weight and inertial force of the material during material transportation, so the thickness of the conveyor belt must withstand these forces to ensure the stability and durability of the conveyor belt.

The thickness of the conveyor belt should be selected according to the characteristics of the material and the working conditions of the conveyor belt. For example, for the transportation of heavy materials, the thickness of the conveyor belt should be thicker to ensure its carrying capacity and stability. At the same time, during high-speed transportation, the inertial force of the material also increases, so the thickness of the conveyor belt needs to be increased accordingly to withstand the inertia and motion of the material.

In addition, the thickness of the conveyor belt is also related to the width of the conveyor belt. Generally speaking, as the width of the conveyor belt increases, its thickness also needs to be increased accordingly to ensure its carrying capacity and stability.

How to determine the optimal thickness of the conveyor belt?

Determined according to the weight of the material: the maximum weight and inertial force generated by the material during transportation are calculated based on parameters such as the density, volume and weight of the material, and then the appropriate thickness is selected according to the carrying capacity and stability of the conveyor belt.

Determined by the width of the conveyor belt: the larger the width of the conveyor belt, the corresponding increase in carrying capacity and stability is required, so its optimal thickness can be determined based on the width of the conveyor belt.

Determined according to the working conditions: The working conditions of the conveyor belt include temperature, humidity, environment and other factors. These factors all affect the performance and life of the conveyor belt, so the appropriate thickness needs to be selected according to the working conditions.

Determined based on empirical values: Select the appropriate thickness based on historical data and experience. For example, for a particular material and delivery method, there are already certain empirical values that can be used as a reference to determine the optimal thickness.