Product features:

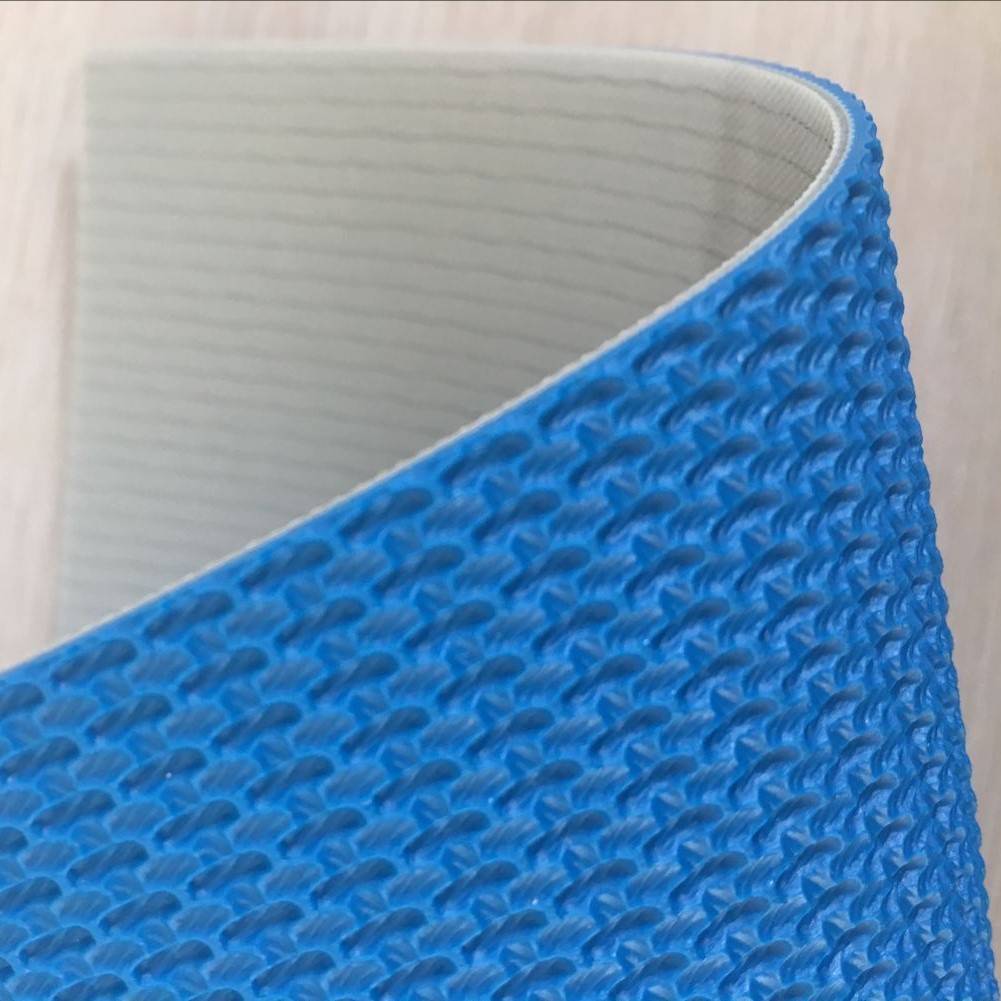

High quality PVC material: Using high quality PVC material, it has excellent properties such as wear resistance, corrosion resistance, high temperature resistance, etc., and has a long service life for a long time.

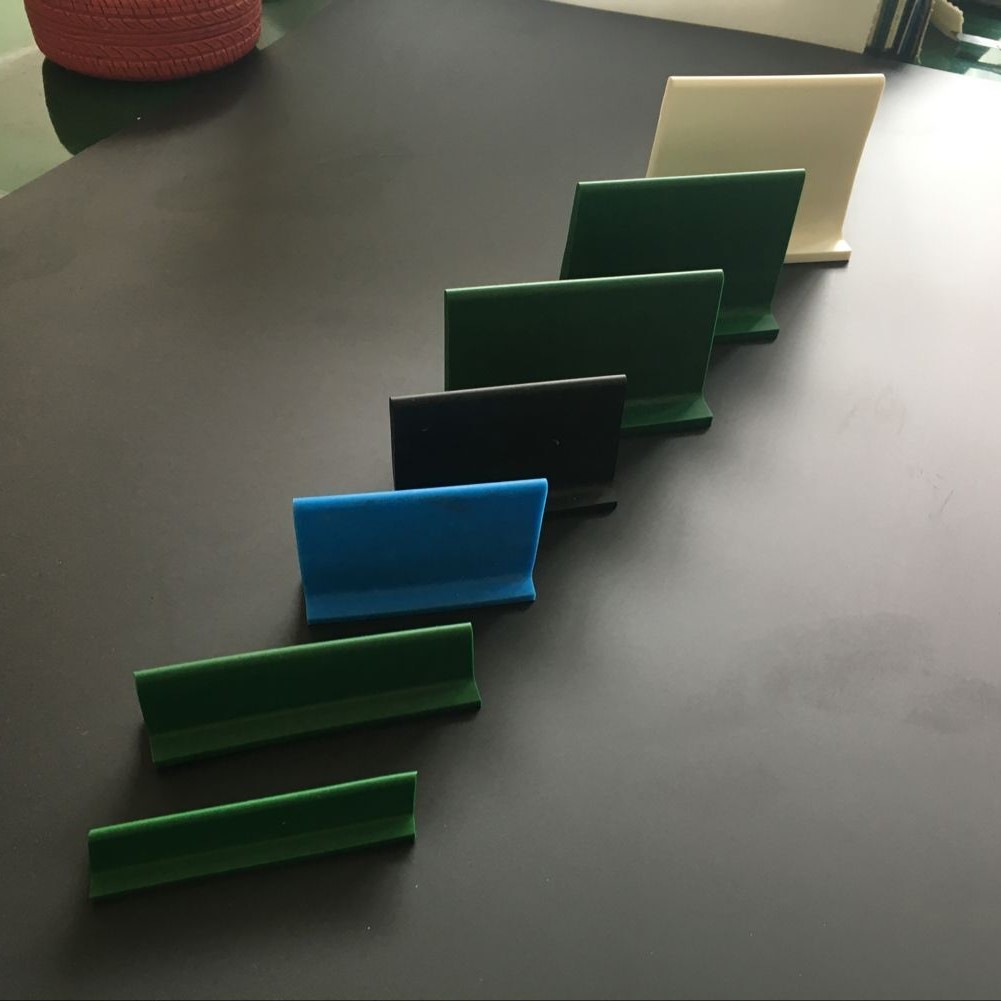

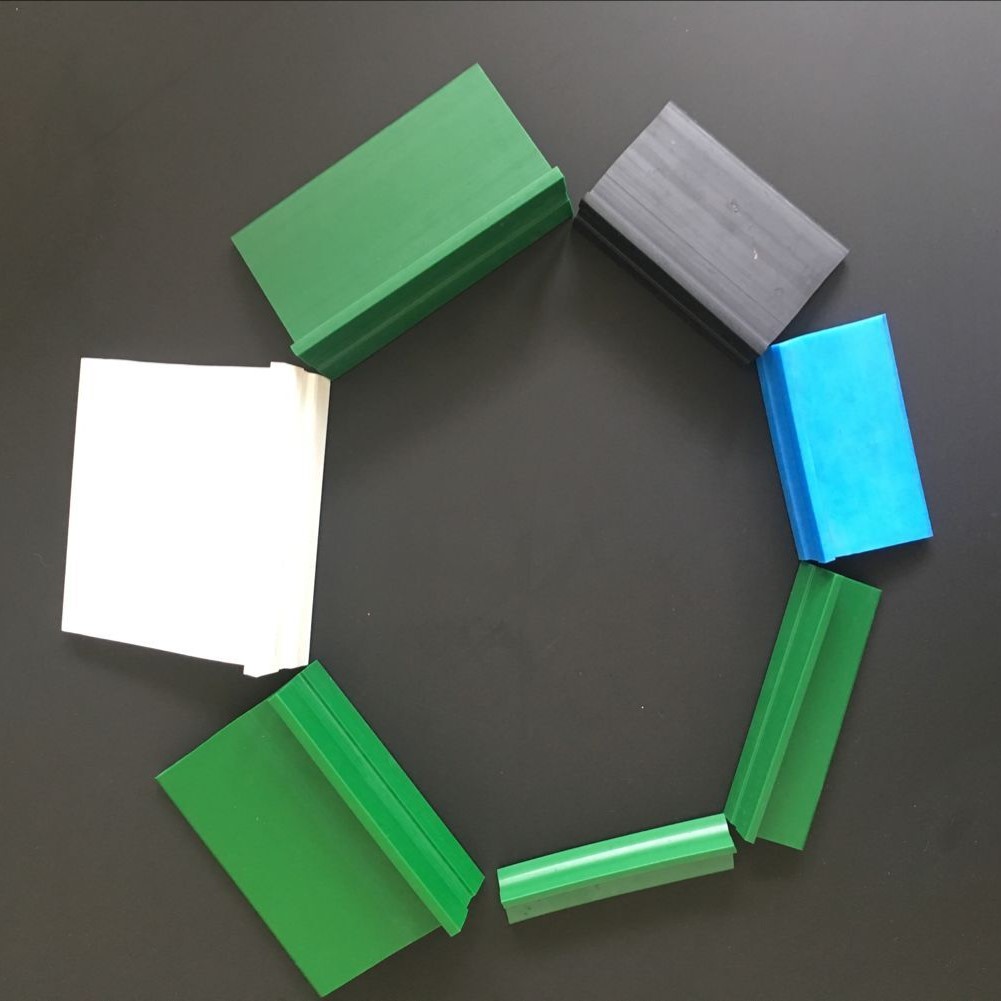

Multiple specifications: A variety of different specifications of clamps and accessories are available, which can be selected according to different conveyor systems and requirements.

Easy to install: The splints and accessories are easy to install and remove, and are easy to maintain and replace.

High accuracy: The clamps and fittings have a high-precision design to ensure the smooth operation of the conveyor belt and reduce failure rate and loss.

Widely applicable: Suitable for a variety of conveyor belt systems, it can be used to transport a variety of goods, including food, chemicals, pharmaceuticals and industrial products.

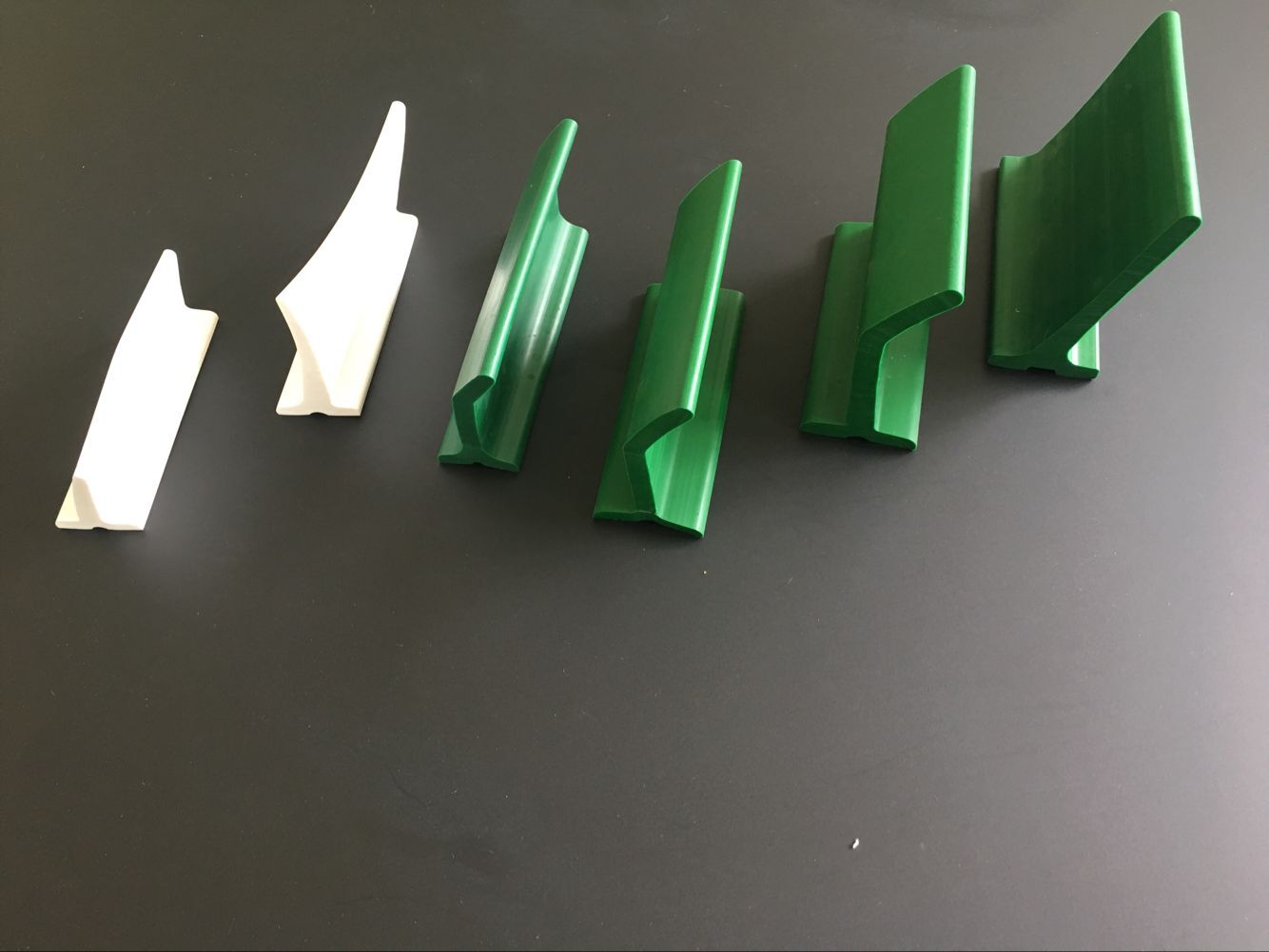

Product model:

- PVC straight splint

- PVC U-shaped splint

- PVC V-splint

- PVC wing splint

- PVC toothed splint

- PVC splint connectors

- PVC splint adjustment parts

How to use:

Choose the right PVC splints and fittings according to the requirements of your conveyor belt system.

Install the splints and fittings in the corresponding positions of the conveyor belt system to ensure a secure installation.

Check the operating status of splints and accessories, and maintain and replace them in a timely manner.

Things to note:

During use, the condition of the splint and accessories should be checked regularly, and if there are any abnormalities, they should be replaced promptly.

During installation and maintenance, you should pay attention to safety to avoid injuries.

During storage and transportation, the splints and accessories should be avoided from being damaged.

PVC clamps and accessories for conveyor belts are a high-quality and efficient conveyor belt system component. They can be applied to various conveyor belt systems and can improve the stability and efficiency of conveyor belt systems. We offer a wide range of clamps and accessories of different specifications, which can be selected according to the different needs of our customers. If you need more information, please contact our sales representatives and we’ll be happy to help.

Replacement details:

Close the conveyor belt system: Before replacing the PVC clamps and fittings, you should first shut down the conveyor belt system and ensure that it does not start unexpectedly.

Remove old splints and fittings: Use appropriate tools to remove old splints and fittings from the conveyor belt system. This may require removing the connecting bolts, loosening the fastening clamps, etc.

Cleaning: The conveyor belt system should be cleaned and its surface clean before installing new splints and fittings.

Install new splints and fittings: Install the new splints and fittings in appropriate locations and fasten them to the conveyor belt system using appropriate tools and fasteners.

Adjustments: Make sure the new splints and fittings are properly installed and that necessary adjustments and positions are made.

Test: Restart the conveyor belt system and perform tests to ensure that the new clamps and fittings are working properly.

Installation check:

Check the installation location: First, check that the new splints and fittings are installed in the correct position and in the correct orientation. If there are multiple splints and fittings that need to be installed, make sure they are installed in the correct order, at the right spacing, and in the right direction.

Fastening: Make sure the new splints and fittings are properly fastened to the conveyor belt system and secured in place using appropriate fasteners and tools. If the splints and fittings need to be connected to other parts, make sure the connections are secure.

Adjustment: Adjust the position and orientation of the new clamps and fittings as needed to ensure that they work in coordination with the rest of the conveyor belt system.

Check the operating status: Restart the conveyor belt system and observe the condition of the new clamps and fittings in operation. Make sure they are not wobbling, vibrating, or making abnormal noises while running, and that they work in coordination with the rest of the conveyor system.