Introduction

The PU Sidewall for Food Grade Conveyor Belt emerges as a pioneering solution tailored to augment efficiency and hygiene standards in food processing industries. This specialized sidewall component is meticulously crafted to elevate the functionality and reliability of food-grade conveyor belts, ensuring superior performance and hygiene compliance throughout the production process.

Premium Attributes and Functions

- High-Quality PU Material

Constructed from premium polyurethane (PU), this sidewall component epitomizes durability and strength. PU is recognized for its resilience against abrasion, chemicals, and wear, making it an ideal choice for maintaining hygienic conditions in food processing environments. Its robust construction guarantees longevity, even in demanding operational settings.

- Customized Design for Food Grade Applications

Engineered specifically for food processing, this PU sidewall is designed to meet stringent hygiene and safety standards. Its specialized design prevents product spillage, contamination, and cross-contamination, ensuring the integrity and purity of food items throughout various processing stages, including conveying, sorting, and packaging.

- Enhanced Hygiene and Safety Compliance

The PU Sidewall for Food Grade Conveyor Belt ensures superior hygiene by minimizing the risk of product contamination. Its smooth, non-porous surface facilitates easy cleaning and sanitation, adhering to stringent food safety regulations. This feature contributes to maintaining a sterile and hygienic production environment, crucial for food-grade operations.

Advantages and Benefits

- Improved Product Quality and Safety

The incorporation of PU sidewalls into food-grade conveyor belts enhances product safety by preventing spillage and contamination. The seamless design promotes hygienic handling, safeguarding the quality and purity of food items throughout the processing journey.

- Enhanced Efficiency and Reliability

The specialized design of the PU sidewall ensures consistent and precise handling of food items. This attribute optimizes operational efficiency, reducing downtime and maintenance while maintaining a steady flow of products along the conveyor line, ultimately improving overall productivity.

- Compliance with Stringent Standards

The PU Sidewall complies with food safety regulations and industry standards. Its food-grade PU material and design ensure adherence to strict hygiene and safety requirements, providing confidence in the integrity and compliance of the conveyor belt system in food processing facilities.

Integration into Food Processing Operations

This PU sidewall seamlessly integrates into various sections of food processing lines, including conveying raw ingredients, sorting, and packaging. Its reliability, functionality, and compliance with food safety standards make it an essential component for maintaining hygiene and efficiency in food processing facilities.

Product features

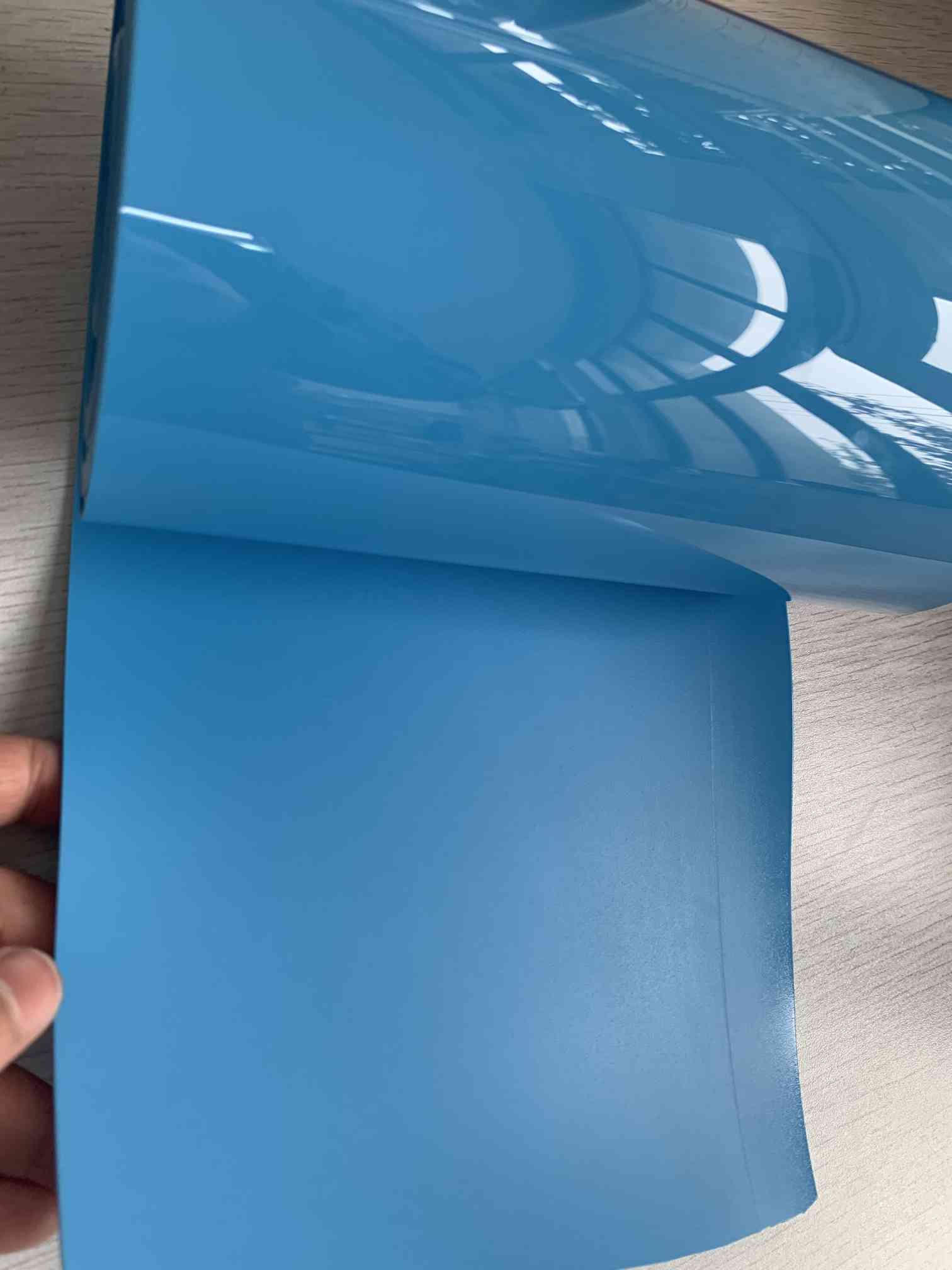

Food-grade materials: This product is made of food-grade PVC materials, meets international food safety standards, and is safe and reliable.

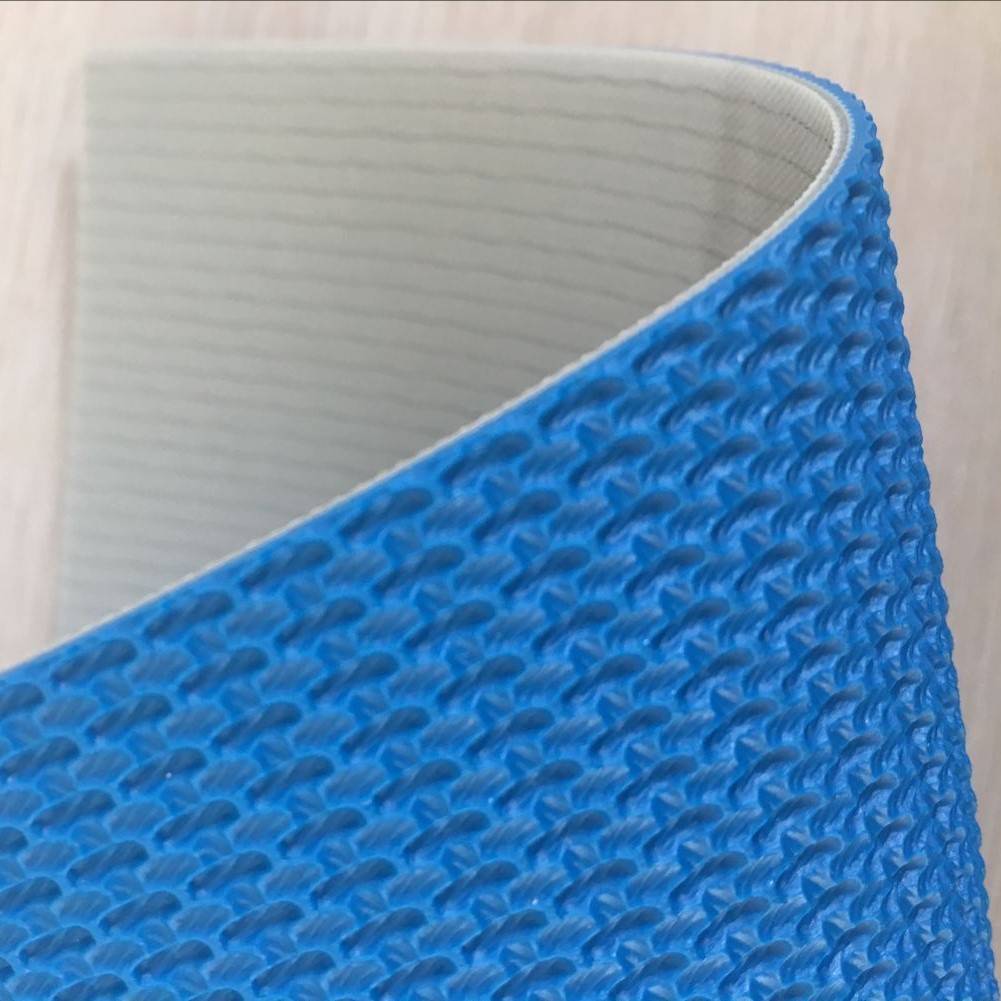

Wear-resistant and anti-slip: The surface of this product uses a special processing technology, which has good wear resistance and anti-slip properties, which can effectively prevent materials from falling and overflowing.

Environmental health: This product is non-toxic and odorless, does not pollute materials, and meets environmental and health requirements.

Multiple color options: This product is available in a variety of colors to suit different industries and application requirements.

Easy to install: This product uses a convenient installation method and can be quickly installed on the conveyor belt without affecting production efficiency.

Product specifications

- Width: 50mm-300mm

- Thickness: 2mm-6mm

- Color: white, blue, red, green and other colors are available

- Length: customized according to your requirements

Application scenarios

This product is suitable for conveyor belt systems in the food, pharmaceutical, chemical and other industries, especially where materials need to be prevented from spilling or falling.

Different industries and application scenarios may require different colors to meet specific needs.

For example, in the food industry, white, blue, or transparent conveyor belts and conveyor belt accessories are commonly used to observe the color and condition of the materials.

In the pharmaceutical industry, white or transparent conveyors and belt accessories are commonly used to easily find and clean up any remaining material.

You need to choose the right color for your specific industry and application scenario.

Installation method

Place the PVC flanges of the food grade conveyor belt on both sides of the conveyor belt and place them parallel to the conveyor belt.

Use screws or clamps to secure the flap to the conveyor belt to ensure that the flap stays stable and does not move.

After installation is complete, check whether the flanges are firm and flat to ensure normal use.

Things to note

Before installation, please check whether the size of the conveyor belt and flanges matches to ensure smooth installation.

Please be safe, use proper tools and safety equipment during installation.

The flanges should be checked regularly during use, and replaced promptly if damaged or worn.

FAQ

Why do you need to use PVC flanges for food grade conveyor belts?

A: The PVC flanges of food grade conveyor belts can prevent materials from spilling or sliding off both sides of the conveyor belt, ensuring the safety, stability and efficiency of the conveying process. In conveyor belt systems in the food, pharmaceutical, chemical and other industries, it is very necessary to use PVC edges for food grade conveyor belts.

What is the material of the PVC edge of a food grade conveyor belt?

A: The PVC flanges of food grade conveyor belts are made of food grade PVC materials, which meet international food safety standards and are safe and reliable.

What colors are available for the PVC flanges of food grade conveyor belts?

A: The PVC flanges of food grade conveyor belts are available in a variety of colors, including white, blue, red, green, etc.

What is the installation method for the PVC flanges of food grade conveyor belts?

A: The PVC flange of the food grade conveyor belt uses a convenient installation method and can be quickly installed on the conveyor belt. The specific installation method is to place the flaps on both sides of the conveyor belt, place them parallel to the conveyor belt, and then use screws or clamps to fix the flanges to the conveyor belt to ensure that the flaps do not move steadily.

What should I pay attention to when it comes to the PVC flanges of food grade conveyor belts?

A: Before installation, please check whether the size of the conveyor belt and flap matches to ensure smooth installation. Please be safe, use proper tools and safety equipment during installation. The flanges should be checked regularly during use, and replaced promptly if damaged or worn.

Can the length of the PVC edge of the food grade conveyor belt be customized?

A: Yes, the PVC edge length of food grade conveyor belts can be customized according to your requirements.

Contact information

For more product information or to order this product, please contact us:

- Tel: +86-510-83312052

- Email: [email protected]

The PVC edge of a food-grade conveyor belt is a type of conveyor belt accessory widely used in food, medicine, chemical and other industries. It has the characteristics of safety, stability and efficiency, and can effectively prevent materials from spilling or slipping and ensure the smooth progress of the production process. We will provide you with high-quality, environmentally friendly, easy-to-install products and excellent services. Please contact us for consultation and order.