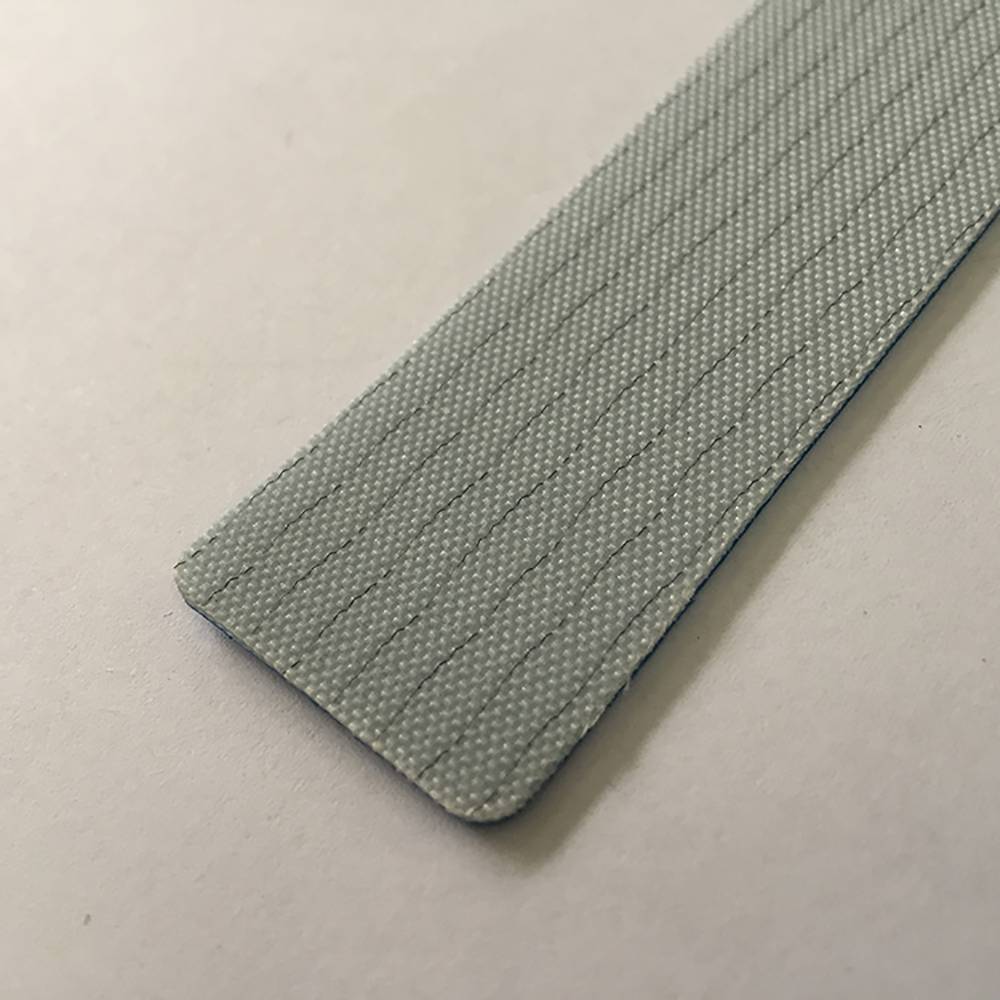

Polyether type belt introduction:

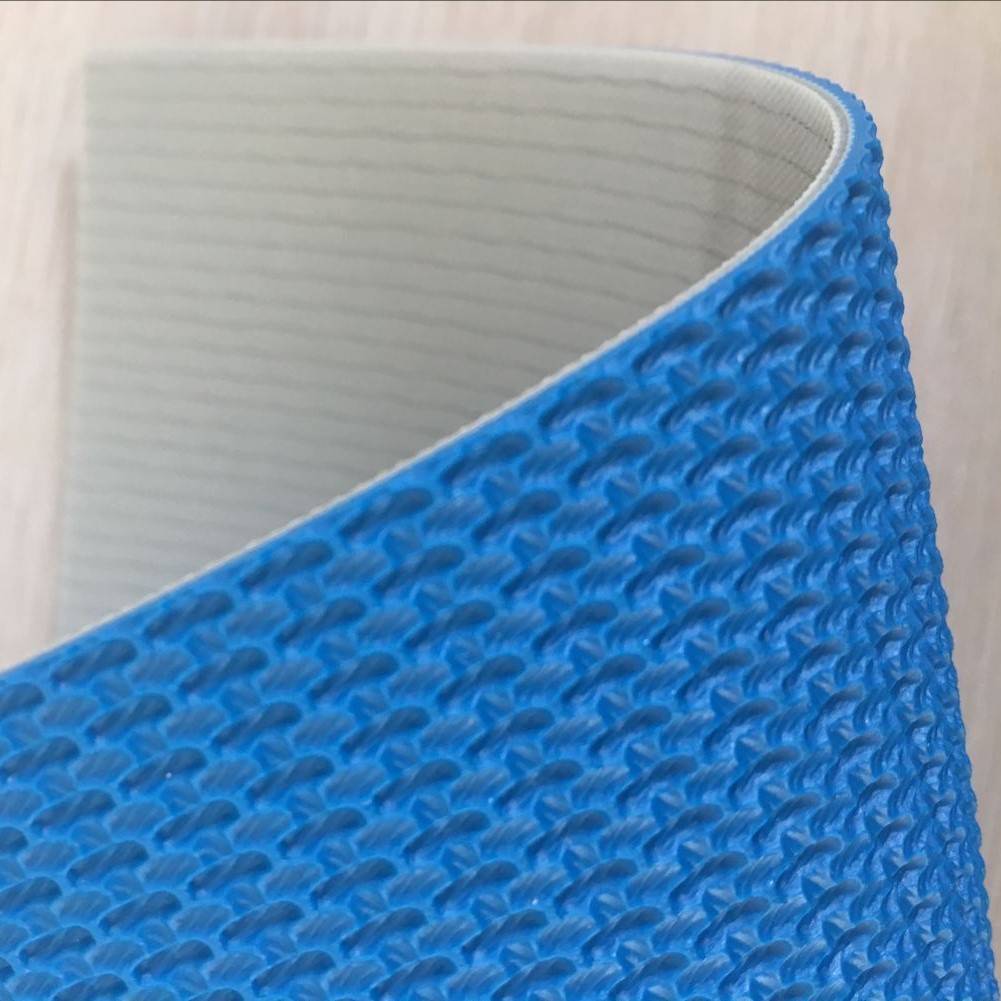

Material: The polyether conveyor belt is made of high quality polyether ester material and has excellent characteristics such as low temperature resistance, hydrolysis resistance, wear resistance and corrosion resistance.

Low temperature resistance: Polyether conveyor belts have good low temperature resistance, can be used normally in low temperature environments below -50℃, and are suitable for cold storage, freezing processing and other fields.

Hydrolysis resistance: Polyether conveyor belts have good hydrolysis resistance, can resist the erosion of hydrolytic substances such as water, moisture, mold, etc., and are suitable for water treatment, cement and other fields.

Wear resistance: Polyether conveyor belts have good wear resistance, can withstand wear under working conditions such as heavy loads, high speeds, and strong impacts, and are suitable for coal mines, building materials and other fields.

Corrosion resistance: Polyether conveyor belts have good corrosion resistance, can resist the erosion of corrosive substances such as acid, alkali, oil, etc., and are suitable for chemical, food processing and other fields.

Other characteristics: Polyether conveyor belts also have good elasticity, tensile strength and pressure resistance, and can meet the requirements of use in different fields.

Installation and maintenance:

Preparation before installation: Before installation, it is necessary to confirm the specification, length, tension, etc. of the conveyor belt, as well as the installation position and direction, etc., to ensure sufficient preparation before installation.

Installation method: The installation of the polyether conveyor belt needs to be carried out in accordance with the installation instructions provided by the manufacturer to ensure the correct installation methods and steps to avoid installation errors or damage.

Check the conveyor belt: Before installation, it is necessary to check the surface of the conveyor belt for damage, wear, cracks, etc., to ensure the quality and integrity of the conveyor belt.

Tension adjustment: After the installation is completed, the tension of the conveyor belt needs to be adjusted to ensure that the tension is uniform and appropriate to avoid excessive or insufficient tension.

Lubrication maintenance: The lubrication maintenance of the Polyether type conveyor belt needs to be carried out regularly to ensure the normal operation and long service life of the conveyor belt. It is important to note that when choosing lubricants, they need to be selected according to the actual working environment and requirements to avoid adverse effects on the conveyor belt.

Regular inspection: The conveyor belt is regularly inspected and maintained, including checking the tension, wear, cracks, etc. of the conveyor belt, and promptly detecting and resolving potential problems to ensure the normal operation and prolongation of the service life of the conveyor belt.

How to use

The corresponding polyether conveyor belt is selected according to the characteristics of the items to be transported to ensure that it can meet the required requirements of wear resistance, chemical corrosion resistance, high temperature resistance, etc.

When installing polyether belts, follow the installation instructions provided by the manufacturer to ensure that the belt is properly installed and adjusted to the correct tension.

Check the wear of the polyether conveyor belt regularly, replace the severely worn parts in a timely manner, and avoid damage caused by wear and tear and production interruption.

During use, the polyether conveyor belt should be cleaned regularly to ensure that its surface is clean and that impurities do not adhere.

When using polyether conveyor belts, overload should be avoided to avoid causing the conveyor belt to break or be damaged.

When using a polyether conveyor belt, you should pay attention to safety to avoid accidents, such as preventing the body and clothing from getting stuck on the conveyor belt, and avoiding dangerous movements during conveyor belt operation.

Cleaning frequency

It is recommended that polyether conveyors are cleaned and maintained at least every quarter to ensure normal use of the conveyor belt.

It is recommended to clean polyether conveyors in the following situations:

Cleaning is necessary when there is significant dirt or impurities on the surface of the transport belt.

When the material being transported is easily contaminated or contains corrosive substances, the polyether conveyor belt should be cleaned regularly to prevent corrosion and damage.

When the surface of the conveyor belt has sticky substances or too much grease, cleaning is necessary to avoid damage to the conveyor belt.

When the ambient temperature of the conveyor belt is high or humid, the cleaning frequency of the polyether conveyor belt should also increase.