Introduction

In the tobacco industry, the Oval Stud PE Tobacco Conveyor Belt stands out as a revolutionary solution designed to optimize efficiency and reliability in tobacco processing and handling. With its unique design and specialized features, this conveyor belt is tailored specifically for the demanding needs of the tobacco manufacturing sector, ensuring seamless operations and enhanced productivity.

Superior Attributes and Functions

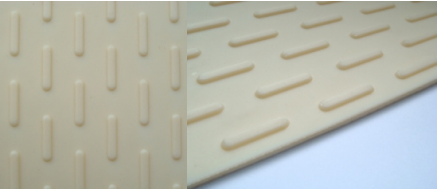

- Oval Stud Design

The Oval Stud PE Tobacco Conveyor Belt boasts a distinctive oval stud pattern, strategically engineered to facilitate optimal material grip and traction. This design feature ensures secure and stable movement of tobacco materials along the conveyor, minimizing slippage and ensuring precise handling throughout the processing line.

- High-Quality PE Material

Crafted from high-quality polyethylene (PE), this conveyor belt guarantees durability and robustness. PE is renowned for its exceptional resistance to abrasion, wear, and chemicals, ensuring longevity even in harsh industrial environments. The material’s low-friction properties contribute to smoother material flow, reducing operational disruptions.

- Customized for Tobacco Processing

Tailored to meet the unique demands of tobacco processing, this conveyor belt is engineered to resist tobacco-specific challenges such as dust accumulation, moisture, and varying product sizes. Its specialized design prevents product degradation and contamination, maintaining the integrity of tobacco products throughout the manufacturing process.

Advantages and Benefits

- Enhanced Efficiency

The Oval Stud PE Tobacco Conveyor Belt significantly improves operational efficiency. Its superior grip and stability minimize product spillage and misalignment, ensuring a continuous and streamlined flow of materials. This efficiency boost translates into increased production rates and reduced downtime, ultimately enhancing overall productivity.

- Reliability and Longevity

Durability is a hallmark of this conveyor belt. The high-quality PE material and robust construction ensure long-lasting performance, minimizing maintenance requirements and replacement costs. Its resistance to wear and tear, along with the specially engineered oval stud pattern, ensures consistent and reliable operation over extended periods.

- Customization for Precision

Tailored customization options allow for precise adaptation to different tobacco processing needs. Whether handling loose leaf tobacco, cut filler, or processed tobacco products, this conveyor belt accommodates various product sizes and types. Its adaptable design ensures optimal performance for each stage of the manufacturing process.

Integration into Tobacco Industry Operations

The Oval Stud PE Tobacco Conveyor Belt seamlessly integrates into various sections of the tobacco manufacturing line, including sorting, drying, cutting, and packaging. Its versatility and reliability make it an ideal choice for conveying raw materials, processed tobacco, and final products within the production facility.

Dimensions

- Regular widths: 300mm, 400mm, 500mm, 600mm, 800mm, 1000mm, etc.

- Regular length: 100 meters, 200 meters, 300 meters, etc.

- Conventional thickness: 3mm, 4mm, 5mm, etc.

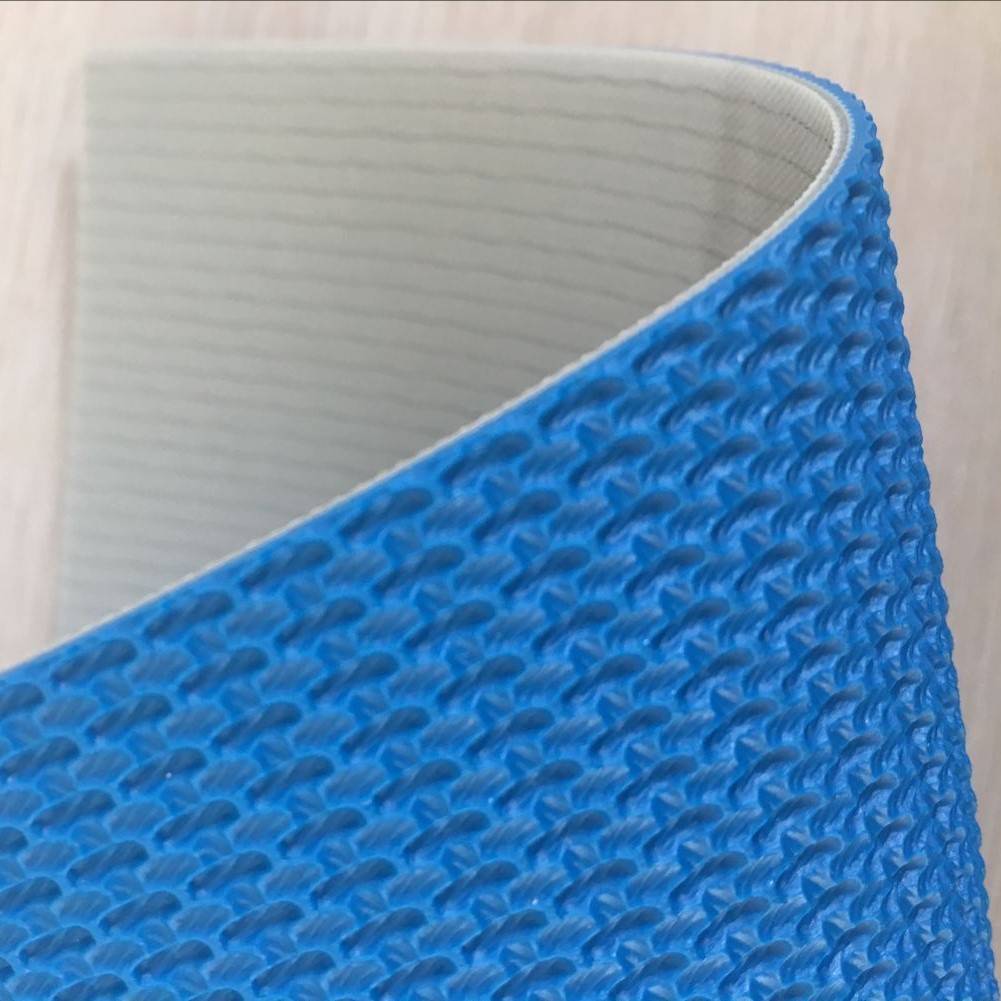

Color

Regular colors: white, gray, blue, green, yellow, etc.

Special colors: Other color customization services can be provided according to customer needs.

Product characteristics

High strength: Oval studs The oval studs on the PE conveyor belt surface can effectively increase friction, improve the carrying capacity and stability of the conveyor belt, and make it have high strength and wear resistance.

Lightweight: Compared with other traditional conveyor belts, oval stud PE conveyors are lightweight, soft, easy to handle and install, and improve work efficiency.

Waterproof, moisture-proof and anti-corrosion: The surface of the oval stud PE conveyor belt is smooth, does not absorb moisture, is not easy to rust or corrode, and has good waterproof, moisture-proof and anticorrosive properties.

Low noise: When the oval stud on the surface of the PE conveyor belt rubs against the item, the noise is low, reducing noise pollution in the working environment.

Easy to clean: The oval stud PE conveyor belt has a smooth surface, is easy to clean, and can be cleaned with a water pipe or detergent to maintain hygiene.

Oval stud design: The oval stud design makes the surface of the conveyor belt more stable, the item is not easy to slide or tilt during transportation, improving the conveying efficiency of the item.

How to use

Before use, the surface and edge of the conveyor belt should be checked for damage or foreign matter to avoid affecting the effect of use.

During installation, it is necessary to ensure that the conveyor belt is properly tensioned to avoid excessive stretching or loosening.

During use, it is necessary to regularly check the wear of the surface and edge of the conveyor belt, and replace the worn parts in a timely manner to extend the service life.

During the cleaning process, you can use a water pipe or detergent to avoid using cleaning agents that are too aggressive to avoid damaging the surface of the conveyor belt.

Cautions

Avoid prolonged exposure of the conveyor belt to sunlight or high temperatures to avoid affecting its performance and service life.

Keep the conveyor belt from coming into contact with all kinds of chemicals and solvents to avoid damage.

Avoid sharp objects or heavy objects being crushed on the surface of the conveyor belt to avoid damage or deformation.

Maintenance

Regularly check the wear of the surface and edge of the conveyor belt, and replace the worn parts in a timely manner.

Clean the surface of the conveyor belt regularly, which can be cleaned with a water pipe or detergent.

When storing the conveyor belt, place it in a dry, ventilated place away from direct sunlight.

Customer stories

logistics company

A logistics company needed to use a conveyor belt in their sorting center to handle a large number of packages. They chose the oval stud PE conveyor belt because it has the characteristics of high strength, light weight, easy to clean, etc., and can effectively reduce noise pollution in the working environment. They ordered a batch of white oval studded PE conveyors with a width of 500mm and a length of 200 meters.

Packaging company

A packaging company needed to handle a large number of boxes using conveyor belts on their production line. They chose the oval stud PE conveyor belt because it can increase friction, improve the carrying capacity and stability of the conveyor belt, thereby ensuring the continuity and stability of the production line. They ordered a batch of blue oval studded PE conveyors with a width of 400mm and a length of 100 meters.

Food processing plants

A food processing plant needs to use conveyor belts on their production line to handle large amounts of food ingredients. They chose the oval stud PE conveyor belt because it has the characteristics of being waterproof, moisture-proof, anti-corrosion, etc., which can ensure the hygiene and quality of food. They ordered a batch of grey oval studded PE conveyors with a width of 600mm and a length of 300 meters.

Mining company

A mining company needs to use conveyor belts to transport ore during their mining process. They chose the oval stud PE conveyor belt because it can improve the efficiency of ore transportation and reduce the sliding and inclination of the ore, thereby improving production efficiency. They ordered a batch of yellow oval studded PE conveyors with a width of 800 mm and a length of 200 meters.

The oval stud PE conveyor belt has the characteristics of high strength, lightness, waterproof and moisture-proof, low noise, easy cleaning and wide application, and can be widely used in logistics, packaging, food processing, metallurgy, mining and other industries. During use and maintenance, attention should be paid to relevant precautions and maintenance measures to extend its service life and improve work efficiency.