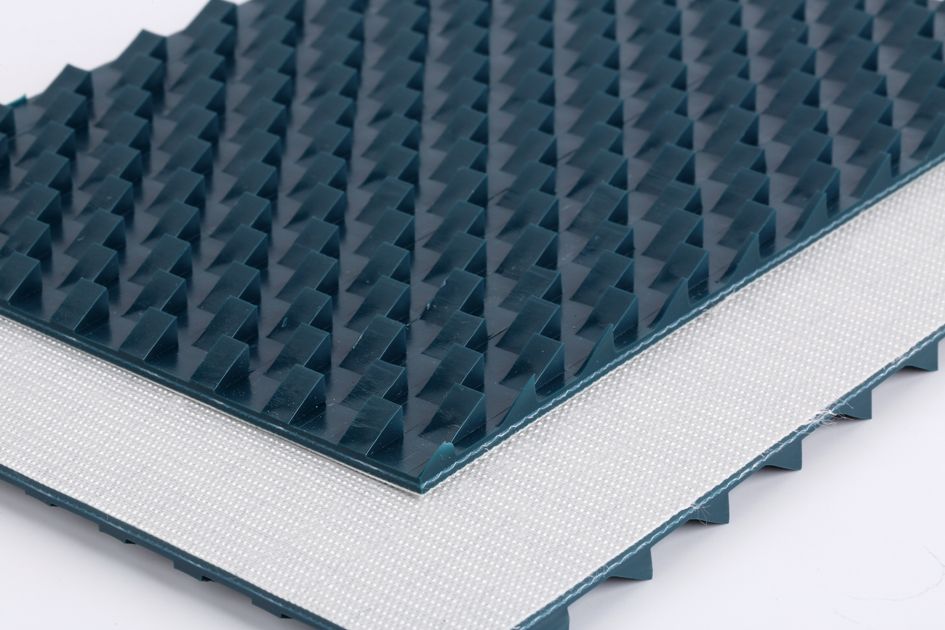

This premium quality saw tooth patterned conveyor belt is specially designed for conveying rough and heavy marble slabs. The raised saw tooth profile provides maximum grip to transport heavy marble materials up steep inclines.

Key Features:

- Made of durable and chemical resistant PVC material with reinforced nylon scrim. Optimum for conveying marble stones.

- Saw tooth pattern with raised V-shaped teeth provides exceptional grip for conveying on inclines. Prevents slipping of heavy and irregular shaped marble slabs.

- Allows single direction travel of materials. The saw tooth pattern grips the material in one direction and allows free sliding in opposite direction. Useful for loading and unloading.

- High impact resistance and tear strength. Withstands heavy marble blocks and impacts.

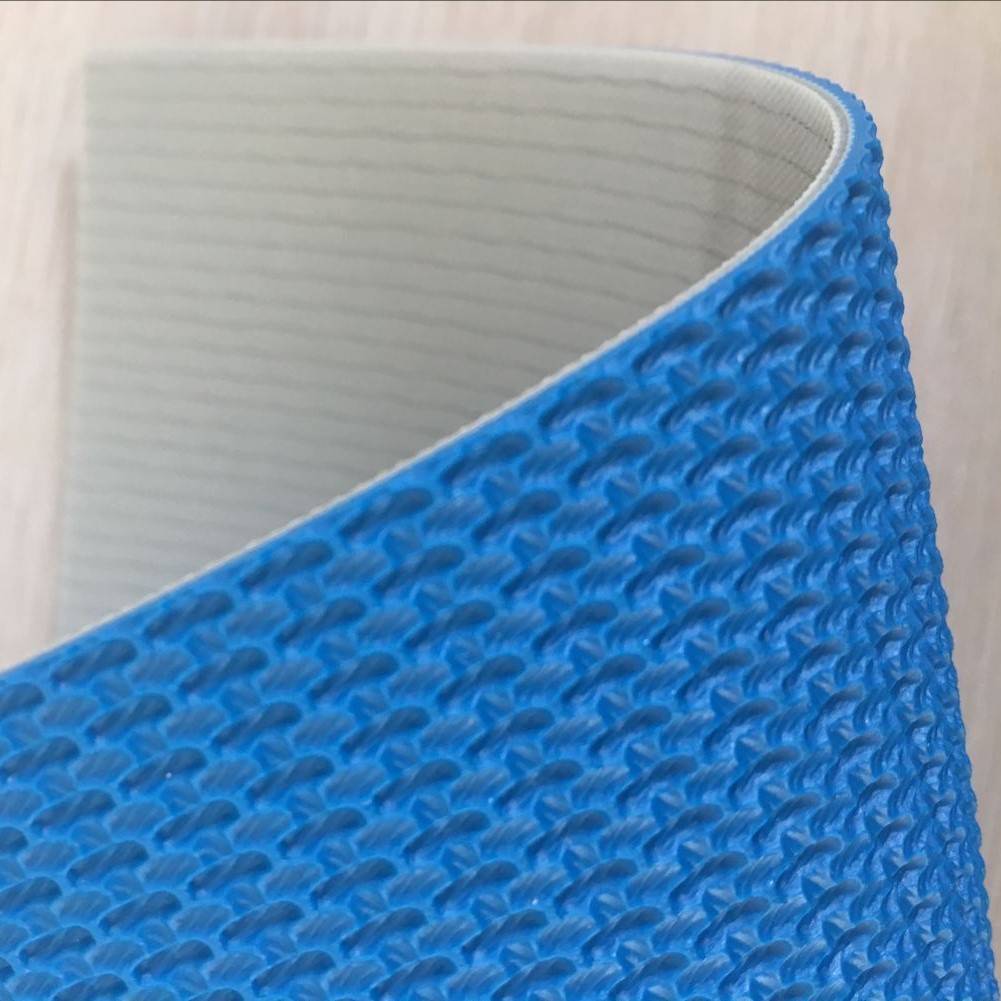

- Flexible and can run over small pulleys and idlers. Fits conveyor structures with tight bends.

- Range of belt widths and lengths available. Thickness from 0.5mm to 2.5mm.

- Available in green and black colours. Transparent also available for visual inspection of belt and material conveyance.

- Cost-effective solution for steep angle and heavy-duty marble conveying.

Are you struggling with transporting heavy and irregular marble slabs at steep angles in your factory? Do your current conveyor belts slip, lose grip or wear out quickly leading to frequent belt replacements?

We have the perfect solution for you – our premium one-way saw tooth PVC conveyor belts are specially engineered for marble conveying applications.

These belts feature a raised saw-tooth pattern that provides maximum grip for conveying marble materials up inclined planes and slopes. The V-shaped teeth grip the underside of the marble firmly, preventing slippage and ensuring efficient material flow. At the same time, the marble can slide freely on the belt when moving opposite to the teeth direction. This allows easy loading and unloading of materials using the same conveyor.

Made of highly durable and chemical-resistant PVC, these belts are built to withstand the immense loads and impacts involved in marble conveying. Their high tear and impact resistance means minimum downtime due to belt damage. The flexible and seamless belt can negotiate tight turns, allowing use in conveyors with small pulleys.

While ordinary belts may need frequent replacement leading to high costs, these long-lasting saw tooth belts are a cost-effective solution for all your inclined marble conveying needs. They provide unmatched performance at an affordable price.

For the best solution to your marble handling woes, switch to our One-way Saw Tooth PVC conveyor belts. They will transform your marble conveying operations and reduce costs due to belt slippage, damage, or frequent replacement. For product details or a free quote, contact us today!

How long does the One-way saw tooth PVC conveyor belt last?

The lifespan of a one-way sawtooth PVC conveyor belt depends on various factors, including the frequency of use, the environment it operates in, and the maintenance practices followed. However, PVC conveyor belts, in general, are known for their durability and long lifespan compared to other types of belts, thanks to their resistance to wear and tear. With proper maintenance and care, a one-way sawtooth PVC conveyor belt can last for several years, providing a reliable and efficient solution for businesses in the marble industry.

Applications:

Suitable for conveying and elevating rough, abrasive and heavy marble blocks in marble quarries and processing units. Effective for loading, unloading, feeding and elevating applications where aggregate materials travel in one direction.

In the food industry, PVC conveyor belts have been used to transport food products safely and hygienically, minimizing the risk of contamination. In the manufacturing industry, PVC conveyor belts have been used to transport products along assembly lines, improving efficiency and reducing labor costs. In the textile industry, PVC conveyor belts have been used to transport fabrics and other materials, ensuring that they remain secure during transport.

Overall, PVC conveyor belts, including the one-way sawtooth PVC conveyor belt, have proven to be a reliable and durable solution for businesses in a variety of industries.

This high-performance one-way PVC saw tooth conveyor belt is an ideal solution for all inclined and heavy marble conveying applications. For more product details or to request a quote, please contact us.

For the marble industry, I would recommend the following custom one-way saw tooth PVC conveyor belts:

- Extra wide conveyor belt: Marble slabs tend to be large in size, so an extra wide conveyor belt, typically 60-100 cm wide would be suitable to handle the large marble plates without too much overlapping or tilting. Wider belts also provide more stability during transit.

- Reinforced and durable construction: The conveyor belts need to withstand the weight and abrasiveness of the marble slabs without damage. So a reinforced PVC belt with thicker, wider, and more durable teeth would be required. Rubber inserts or covers over the teeth can provide extra protection.

- Non-skid/non-slip design: The teeth on the conveyor belt need to Grip the marble slabs securely during transit without slipping. Deeper, wider and more closely spaced saw teeth designs with a non-skid surface can provide a very good grip on marble and other stone slabs.

- Smooth bottom side: While the top side with teeth is necessary to grip the marble, a smooth bottom side prevents the stone slabs from getting hooked or stuck. A smooth bottom side allows the slabs to slide easily over the belt.

- Temperature resistance: Some marble processing may involve heating, so the conveyor belts should be able to withstand higher temperatures without damage. PVC belts can typically handle up to 60-70°C.

- Washable and chemical resistant: The conveyor belts may get stained or soaked in marble abrasives and polishes from time to time. So a washable, non-porous, and chemical-resistant material like PVC works well for the marble industry.