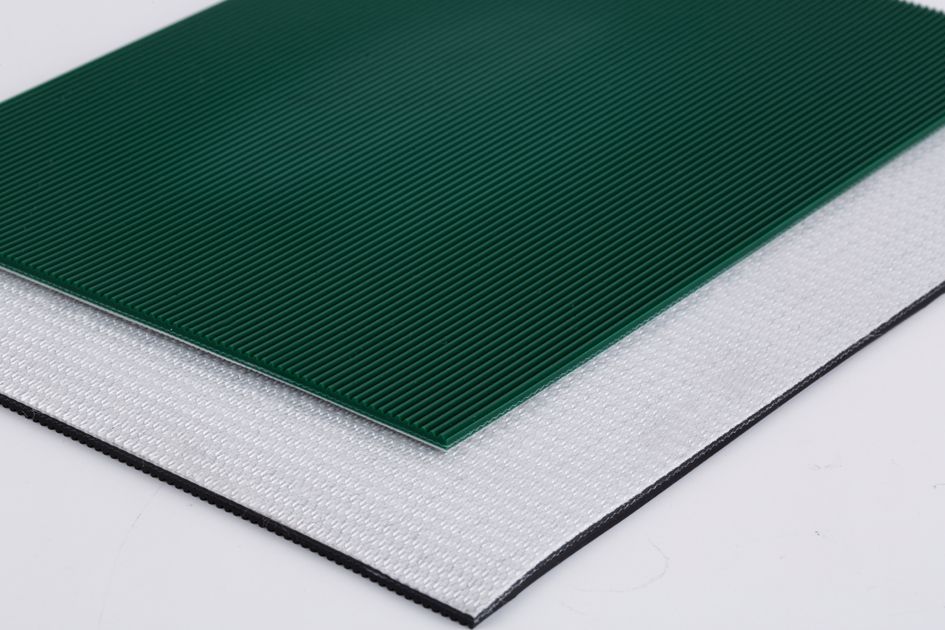

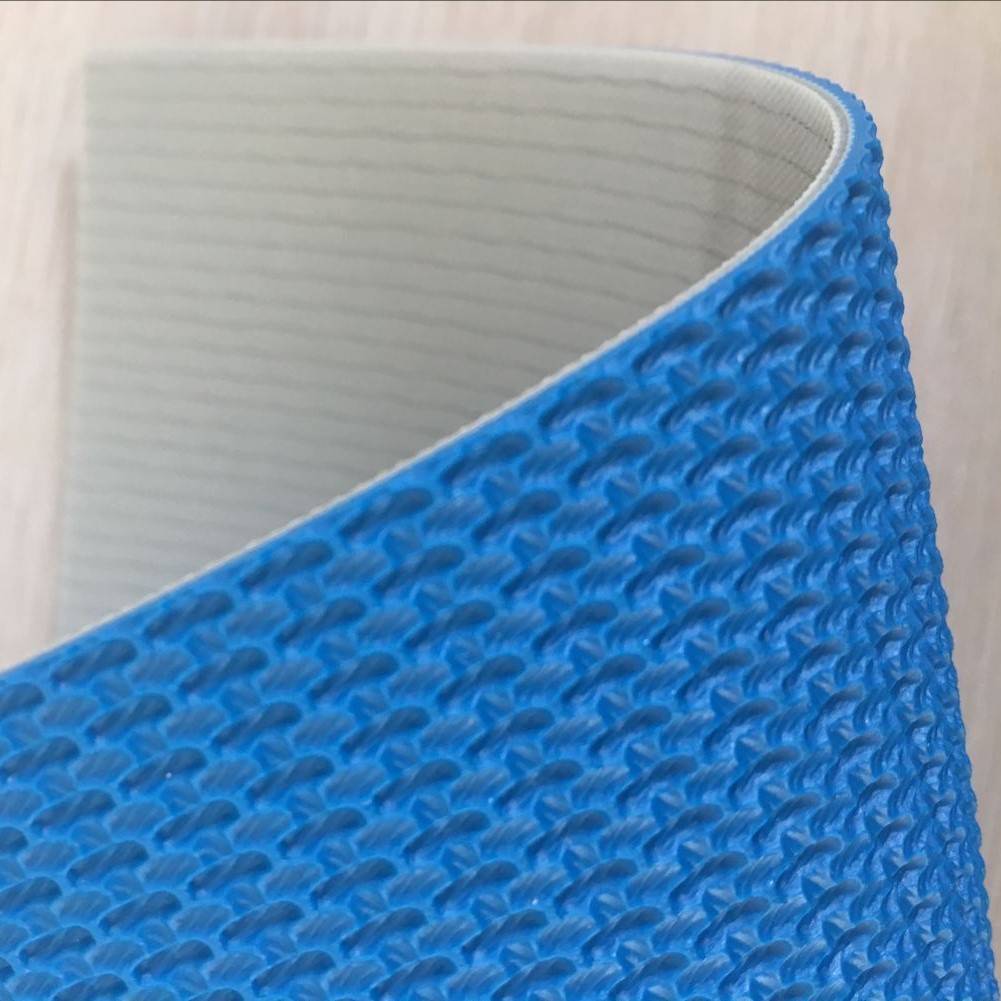

Introducing our Lozenge pattern rough surface PVC conveyor belt – the perfect solution for your industrial needs! Made from high-quality PVC material, this conveyor belt is designed with a non-slip, rough surface that ensures the safe and efficient transportation of your products.

The unique Lozenge pattern on the surface of the belt provides excellent grip and stability, making it ideal for use in applications where slippery or fragile items need to be transported. The rough surface also helps to prevent product damage and reduces the risk of slippage, ensuring that your operations run smoothly and efficiently.

The Lozenge pattern on our rough surface PVC conveyor belt is a unique design that offers several advantages compared to other rough surface patterns.

-

Better grip: The Lozenge pattern provides a superior grip compared to other rough surface patterns. The pattern is designed to interlock with the items being transported, ensuring that they stay in place and don’t slip or slide.

-

Reduced wear and tear: The Lozenge pattern is designed to reduce wear and tear on the belt itself. The pattern distributes the load more evenly across the belt surface, reducing the risk of damage or premature wear.

-

Increased durability: The Lozenge pattern is highly durable and can withstand heavy loads and harsh environments. The pattern is designed to resist damage and maintain its grip even under challenging conditions.

-

Reduced noise: The Lozenge pattern is designed to reduce noise levels during operation. The pattern minimizes vibrations and noise, making it a quieter option compared to other rough surface patterns.

-

Improved cleanliness: The Lozenge pattern is easy to clean and maintain, making it a more hygienic option compared to other rough surface patterns. The pattern is less likely to trap dirt or debris, ensuring that the belt remains clean and sanitary.

Our Lozenge pattern rough surface PVC conveyor belt is highly durable and can withstand heavy loads, making it ideal for use in a wide range of industries, including manufacturing, logistics, and packaging. It is also easy to clean and maintain, ensuring that it remains in top condition for longer.

-

High-quality material: Our Lozenge pattern rough surface PVC conveyor belt is made from high-quality PVC material that ensures durability, longevity and high performance.

-

Non-slip surface: The rough surface of our conveyor belt provides excellent grip, stability and prevents slippage. It is ideal for transporting slippery or fragile items safely and efficiently.

-

Prevent product damage: The rough surface of our conveyor belt reduces the risk of product damage during transportation, ensuring that your products arrive in perfect condition.

-

Versatility: Our Lozenge pattern rough surface PVC conveyor belt is suitable for a wide range of industries, including manufacturing, logistics, and packaging.

-

Easy to clean: Our conveyor belt is easy to clean and maintain, ensuring that it remains in top condition for longer.

-

Cost-effective: Our conveyor belt is competitively priced and offers great value for money. You can be sure that you are getting the best possible solution for your budget.

-

Durability: Our conveyor belt is highly durable and can withstand heavy loads, making it ideal for use in demanding industrial applications.

-

Excellent Customer Service: We are committed to providing excellent customer service. Our team is always here to help you with any questions or concerns you may have, ensuring that you get the most out of our Lozenge pattern rough surface PVC conveyor belt.

With our Lozenge pattern rough surface PVC conveyor belt, you can be confident that your products will be transported safely and efficiently, while maintaining the highest standards of quality and reliability. Order now and experience the difference that our conveyor belt can make to your operations!

The appropriate belt width depends on several factors, including:

- The width of items you need to convey – The belt should be wide enough to stably support the items. As a general rule of thumb, for small to medium sized items, a belt width 6-12 inches wider than the item width is a good starting point. For larger items, at least 12-24 inches wider.

- Capacity or volume of items – Wider belts allow for higher throughput and volume. If you need to move a high volume of items, a wider belt may be required.

- Speed of the belt – Wider belts can handle higher speeds without instability or tracking issues. For high-speed conveyor lines, a wider belt is usually better.

- Available space – The space you have available for the conveyor line and belt may also dictate the maximum belt width.

- Future needs – If your conveyor needs or item sizes may increase in the future, you’ll want to consider a belt width that can accommodate that potential growth. It is often better to start with a belt that is slightly wider than your current needs.

Given this, the most balanced recommendation I can provide would be to consider a belt width in the 24 to 36 inch range, assuming you are conveying medium to larger sized items.

At this size, it should accommodate moderate volumes and speeds, have room for some growth, and provide good stability for most items. But please validate this with the specifics of your own system and requirements. The ideal belt width for your application may be wider or narrower.