Product features:

High efficiency and energy saving: High-frequency machines use high-frequency electromagnetic fields for processing. The conversion efficiency is high, energy consumption is low, and energy is saved.

High precision: The welding, sealing, cutting and other processes of high-frequency machines can be precisely controlled and have excellent processing accuracy.

Stable and reliable: The high-frequency machine uses advanced electronic control technology and stable and reliable electronic components to ensure the stability and reliability of the equipment.

Easy to operate: The high-frequency machine has a user-friendly operation interface and a simple to understand operation process, which is easy to operate.

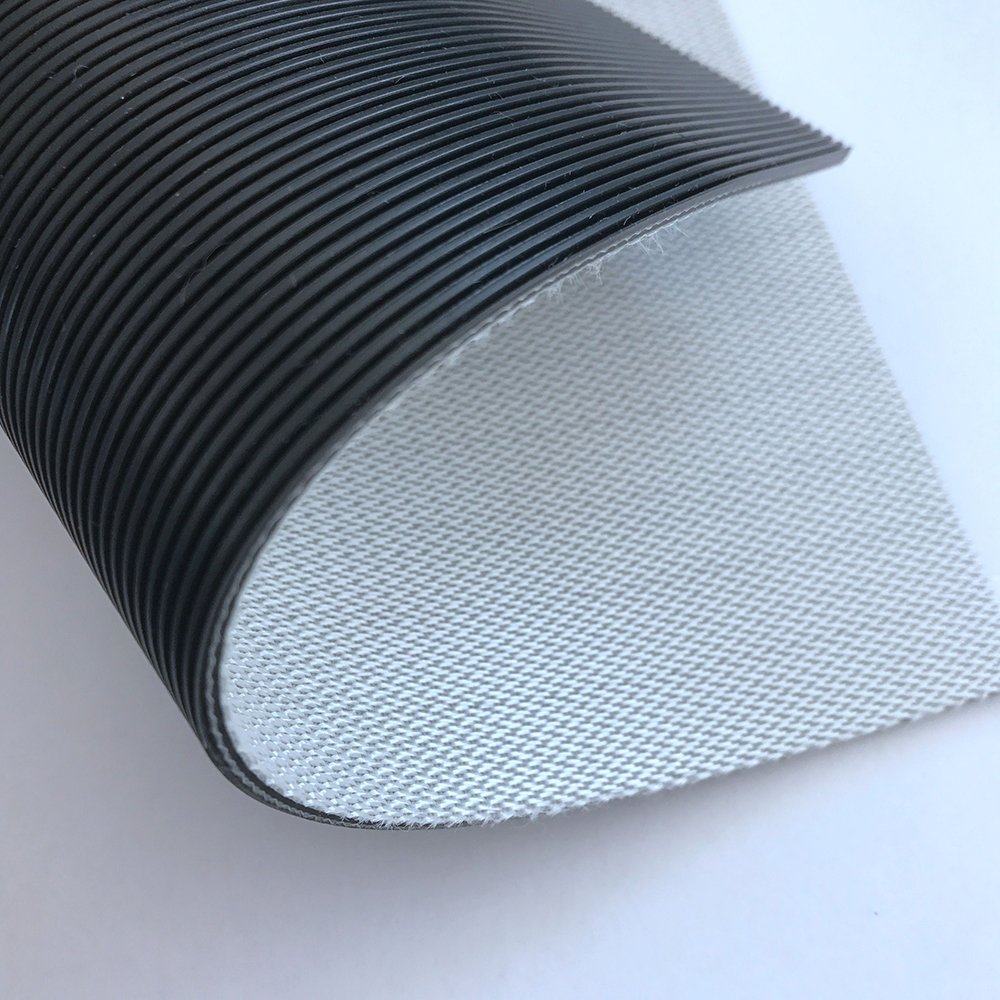

Wide range of applications: High-frequency machines can be applied to the processing of various materials, including metals, plastics, rubber, textiles, etc.

Technical parameters:

- Input power: AC 220V/380V 50/60Hz

- Output power: 1kW-50kW

- Operating frequency: 20kHz-500kHz

- Processing speed: 0.5m/s – 5m/s

- Processing accuracy: ± 0.1 mm

- Processing materials: metal, plastic, rubber, textiles, etc.

- Equipment size: Depends on different models

Areas of application:

High-frequency machines are widely used in automobile manufacturing, electronics industry, construction industry, manufacturing and other industries. It can be used to weld automotive parts, electronic components, construction materials, etc., as well as to seal plastic bags, cut rubber pipes, etc.

Repairs and maintenance

Regular cleaning: Some dust and impurities will accumulate inside the high-frequency machine, affecting the cooling and operating efficiency of the equipment. Therefore, it is necessary to regularly clean the interior of the high-frequency machine, especially components such as radiators and fans.

Lubrication maintenance: High-frequency machine components need to be lubricated regularly to reduce wear and improve equipment stability. The choice of lubricant should be based on the equipment manufacturer’s recommendations.

Check the power supply: High-frequency machines require stable power support, so it is necessary to check whether the power line is normal regularly. If a problem with the power supply is found, it should be promptly repaired or replaced.

Check the cooling system: The cooling system of high-frequency machines requires regular inspection, especially parts such as water pumps and water pipes. If problems are found, repairs or replacement should be carried out promptly.

Regular calibration: The processing accuracy of high-frequency machines requires regular calibration to ensure processing quality and accuracy. Calibration should be performed by a professional to avoid misoperation.

Prevent overload: High-frequency machines need to avoid overloading operation, otherwise they will damage the equipment or affect processing quality. Therefore, during use, care should be taken to control parameters such as processing load and processing speed.

Regular maintenance records: In order to facilitate maintenance and track equipment usage, it is necessary to regularly record equipment maintenance and repair records. This helps identify and resolve issues in a timely manner, and improves the stability and reliability of the equipment.

After-sales service:

Installation and commissioning: After-sales service personnel will visit your site to install and debug the equipment to ensure the normal operation of the equipment.

Training service: After-sales service personnel will train you in equipment operation and maintenance, so that you can understand how to use the equipment and precautions, and improve the efficiency and stability of the equipment.

Maintenance service: If there is a problem with the equipment, after-sales service personnel will promptly go to your site to repair and replace parts to ensure the normal operation of the equipment.

Spare parts supply: After-sales service personnel will supply the spare parts required for the equipment, so that you can replace parts in time to ensure the stability and reliability of the equipment.

After-sales support: After-sales service personnel will provide long-term technical support and consulting services to answer your questions and problems and provide you with professional technical support.

Regular maintenance: After-sales service personnel will regularly maintain the equipment, check the operating condition and performance of the equipment, and ensure the stable operation of the equipment for a long time.

After-sales feedback: After-sales service personnel will communicate with you regularly to understand your usage and feedback, resolve problems and improve services in a timely manner.