Introduction

In the realm of gypsum industry manufacturing, the Gray PVC Conveyor Belt stands as a testament to innovation and efficiency. Specifically crafted to meet the unique demands of gypsum production, this specialized belt redefines material handling, ensuring seamless conveyance throughout various manufacturing stages.

Attributes of the Gray PVC Conveyor Belt

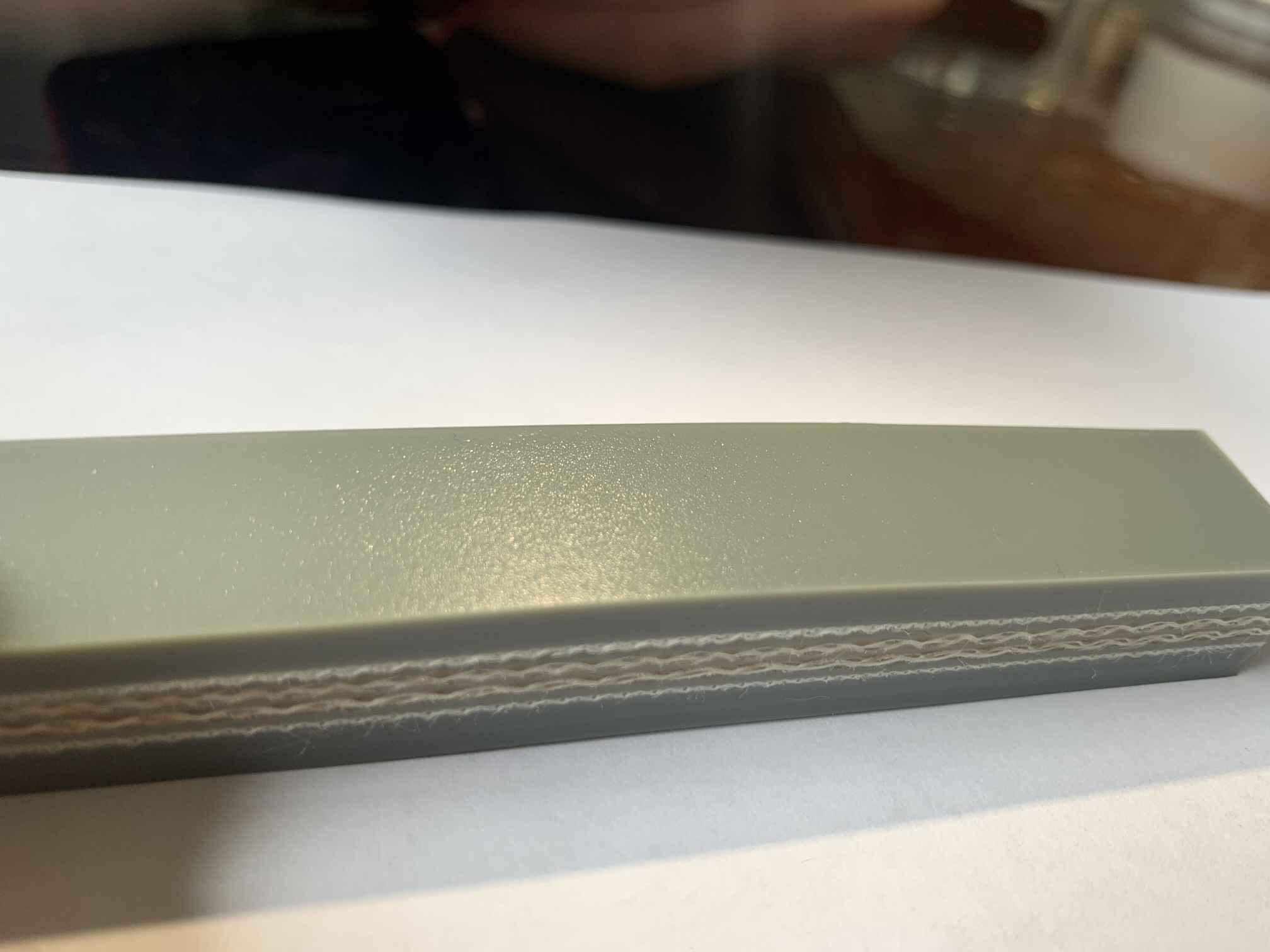

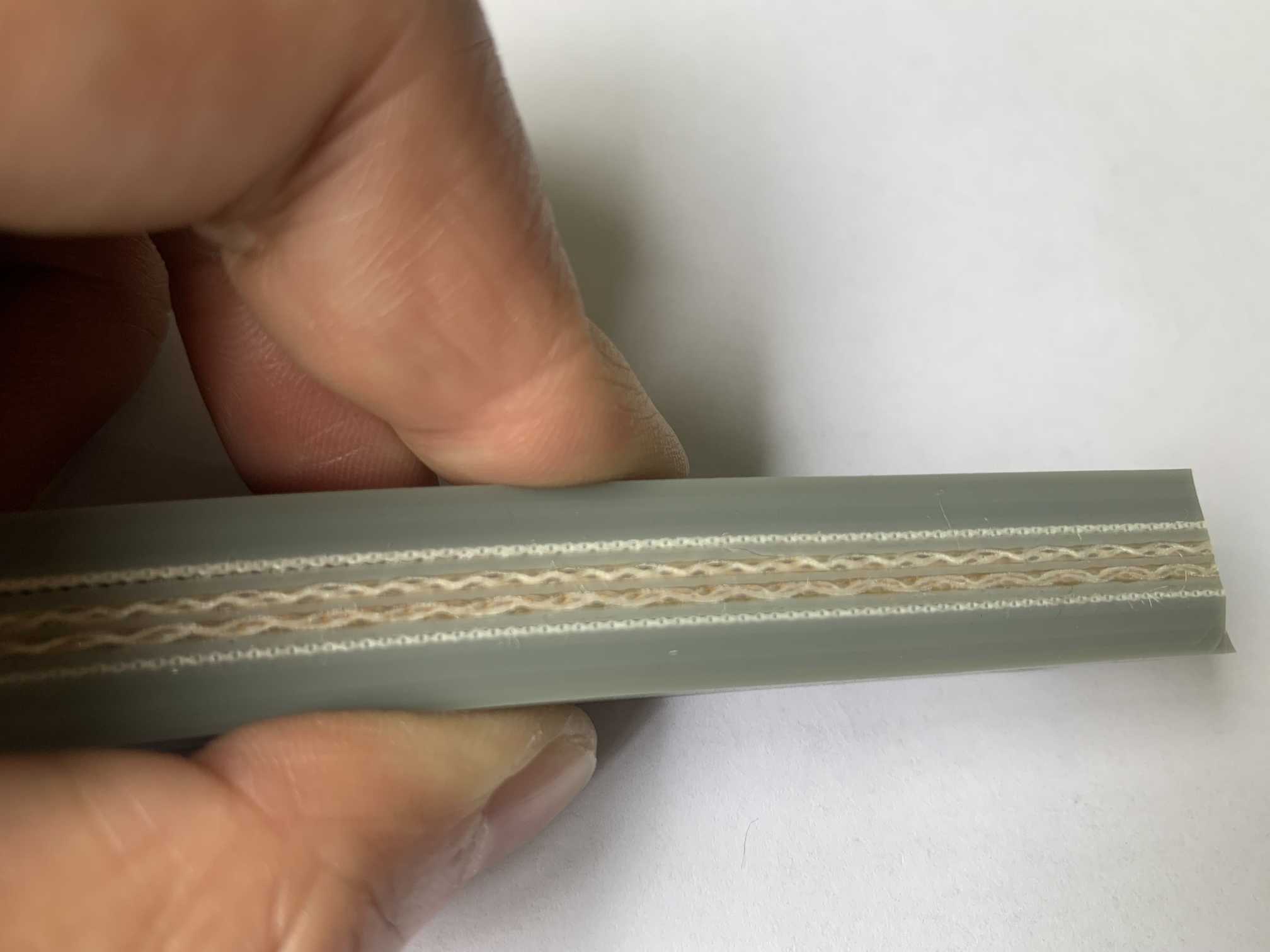

Durable PVC Material Composition

Crafted from top-quality Polyvinyl Chloride (PVC), this conveyor belt epitomizes durability and resilience. The PVC material used in its construction boasts exceptional resistance to abrasion, chemicals, and moisture, ensuring prolonged service life even in harsh operational environments.

Significance of Gray Color Specification

The deliberate choice of a gray hue in the belt’s design is far from arbitrary. Beyond aesthetics, the gray color holds functional significance within the gypsum industry. Its ability to mask potential surface impurities or dust often found in gypsum materials contributes to a visually cleaner appearance, ensuring product quality and adherence to industry standards.

Functions and Operational Advantages

Efficient Material Conveyance

The Gray PVC Conveyor Belt is tailored to facilitate the seamless transportation of gypsum materials across various stages of production. Its smooth surface texture allows for efficient conveyance, ensuring a consistent flow of materials critical for uninterrupted manufacturing processes.

Compatibility with Gypsum Handling

The belt’s design factors in the unique handling requirements of gypsum materials. Its surface texture and durability are specifically engineered to withstand the abrasive nature of gypsum, preventing material degradation and maintaining the integrity of the conveyed product.

Advantages for Gypsum Industry Manufacturers

Enhanced Productivity

This conveyor belt plays a pivotal role in enhancing productivity within gypsum manufacturing facilities. Its design ensures a smooth, controlled material flow, reducing bottlenecks and enhancing overall operational efficiency.

Reduced Downtime and Maintenance

The durability and resilience of the Gray PVC Conveyor Belt significantly reduce maintenance requirements and operational downtime. Its resistance to wear and tear minimizes the need for frequent replacements, translating into cost savings for gypsum industry manufacturers.

Applications and Industry Integration

Critical Component in Gypsum Production

As a critical component in the gypsum manufacturing process, this conveyor belt facilitates material handling from raw gypsum extraction to the final stages of production, ensuring a streamlined workflow and efficient operations.

Seamless Integration into Gypsum Machinery

Designed for compatibility, this specialized belt seamlessly integrates into a myriad of gypsum industry machinery and conveyor systems. Its standardized dimensions and configurations allow for effortless installation and operational consistency.

Product introduction

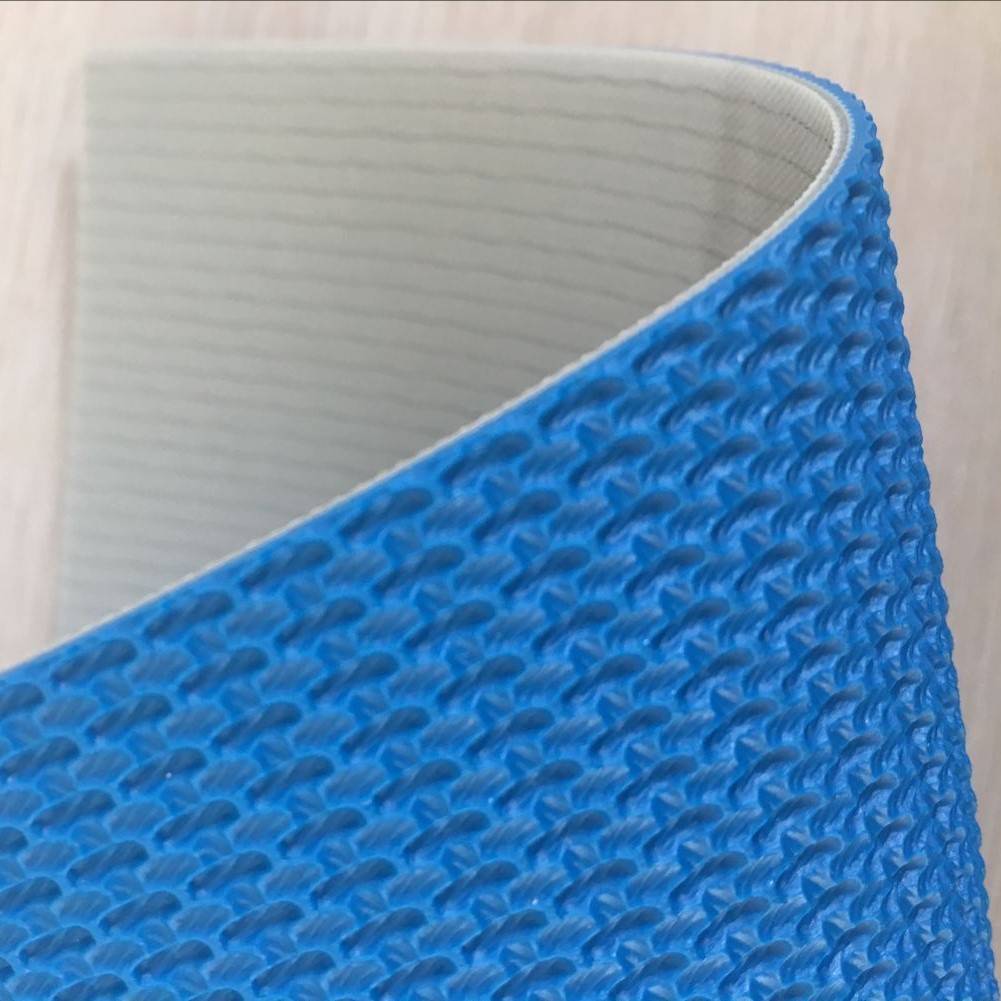

The surface design of Grey PVC Coated Belt for Gypsum Industry has a variety of patterns to choose from, such as horizontal stripe patterns, fish bone patterns, grid patterns, etc. These patterns can increase the contact area with the material, improve the friction and grip of the material, thereby reducing the sliding and deviation of the material during transportation and increasing the stability of the material.

The thickness of the conveyor belt has also been carefully designed to fully withstand the weight and inertia of the material and ensure the stability and durability of the conveyor belt.

Product features

The gray surface design has a beautiful and stylish appearance, suitable for various occasions.

High quality PVC material with excellent wear resistance, corrosion resistance and high temperature resistance.

A variety of surface patterns can be selected to increase the contact area with the material and improve the stability of the material.

The carefully designed thickness can fully withstand the weight and inertia of the material to ensure the stability and durability of the conveyor belt.

Conveyor belts of different specifications and lengths can be customized according to customer needs to meet different material conveying requirements.

FAQ

What is the maximum operating temperature of PVC conveyor belts?

A: The maximum operating temperature is 80℃.

What thickness specifications can I choose from Grey PVC Coated Belt for Gypsum Industry?

A: The thickness of the conveyor belt is available in various specifications such as 1.5mm, 2mm, 3mm, 4mm, and 5mm.

Is there a limit on the length of the gray PVC conveyor belt?

A: The length of the gray PVC conveyor belt can be customized according to customer needs, and there is no fixed limit.

Will the gray PVC conveyor belt break during use?

A: Grey PVC Coated Belt for Gypsum Industry is made of high-quality PVC materials. After careful design and processing, it has excellent wear resistance, corrosion resistance and high temperature resistance, and is not easy to break.

Does the surface pattern of Grey PVC Coated Belt for Gypsum Industry affect the conveying effect of the material?

Answer: The surface pattern of the gray PVC conveyor belt is to increase the contact area with the material, improve the friction and grip of the material, thereby reducing the sliding and deviation of the material during transportation and increasing the stability of the material. Therefore, the surface pattern has a positive effect on the conveying effect of the material.

What issues should I pay attention to when installing gray PVC conveyor belts?

A: When installing a gray PVC conveyor belt, you need to pay attention to the direction and tension of the conveyor belt to ensure the normal operation of the conveyor belt. At the same time, it is also necessary to pay attention to the maintenance and maintenance of the conveyor belt, regularly clean, lubricate and check the degree of wear of the conveyor belt, replace seriously worn parts in a timely manner, and extend the service life of the conveyor belt.

How to clean and lubricate grey PVC conveyor belts?

A:

Cleaning:

Clean the material on the conveyor belt first to prevent dirt from adhering to the conveyor belt.

Clean the conveyor belt with clean water or neutral detergent, and avoid using detergent with strong acid and alkali properties.

After cleaning with water, wipe off the surface moisture of the conveyor belt with a clean towel to prevent accumulated water from causing damage to the conveyor belt.

Lubrication:

Spray an appropriate amount of lubricant on the working surface of the conveyor belt. The type of lubricant should be determined according to the material of the conveyor belt and the working environment.

Lubricant should be sprayed evenly to avoid excess or too little.

The time for lubricating oil should be sprayed according to the usage of the conveyor belt, generally once every certain period of time.

How to avoid wear and tear on Grey PVC Coated Belt for Gypsum Industry?

Avoid overloaded use of the conveyor belt: The load of the conveyor belt should be within the range that the conveyor belt can withstand, and avoid overloaded use to reduce wear and tear.

Avoid reverse running of the conveyor belt: The direction of the conveyor belt should be consistent to avoid frequent reverse operation to reduce wear.

Control the speed of the conveyor belt: The speed of the conveyor belt should be properly controlled to avoid being too fast or too slow to reduce wear.

Prevent the surface of the conveyor belt from being scratched by sharp objects: The surface of the conveyor belt should be kept clean and avoid contact with sharp items to reduce scratches and wear.

Regularly check the wear of the conveyor belt: Check the wear of the conveyor belt regularly and replace parts with severe wear in a timely manner to extend the service life of the conveyor belt.

Choose high-quality gray PVC conveyor belts for the gypsum industry: High-quality gray PVC conveyors for the gypsum industry have the characteristics of wear resistance, corrosion resistance and high temperature resistance, which can reduce wear and damage.

This product is widely used in various industrial fields such as gypsum production lines, gypsum board production lines, gypsum powder production lines, etc. If you are looking for a high quality, stable conveyor belt for the gypsum industry, then our Grey PVC Coated Belt for Gypsum Industry is definitely your best choice.