Product advantages:

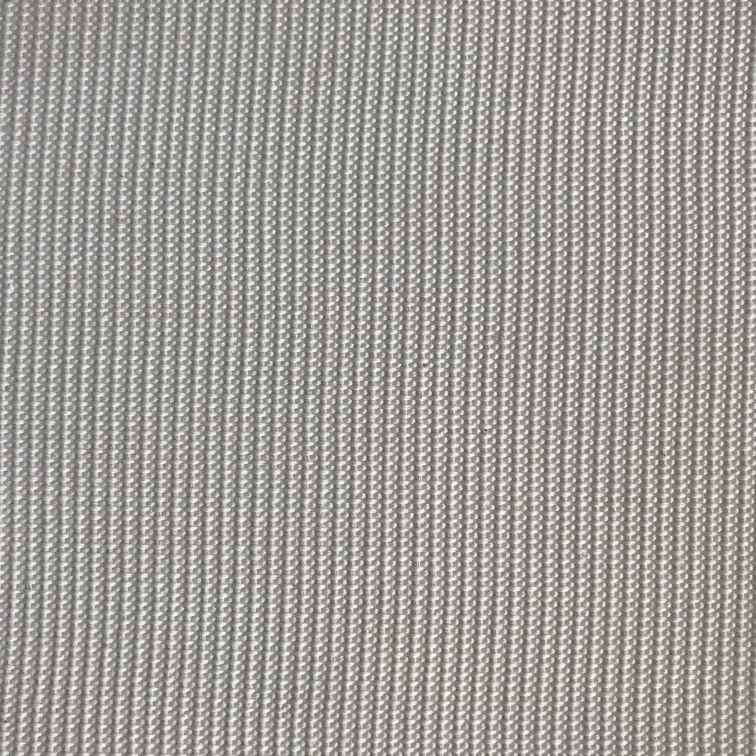

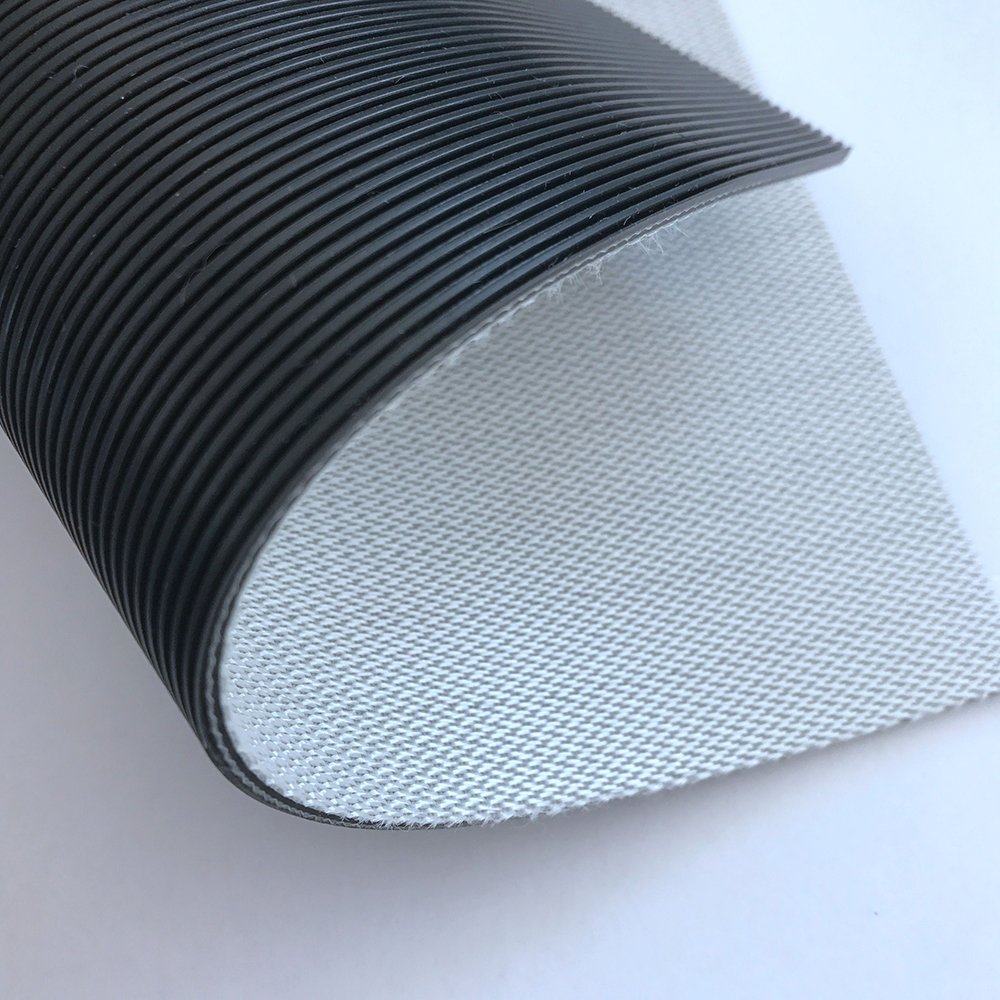

Double-sided deformation design: The product uses double-sided deformation technology, that is, a unique layer of deformation adhesive is applied to the surface of the cotton conveyor belt, so that the conveyor belt can automatically adapt to different working environments, ensure that the conveyor belt always runs smoothly, and reduces equipment maintenance costs.

Lightweight and durable: The product uses high-quality cotton material, which is lightweight, soft and durable, which can not only effectively reduce equipment noise, but also effectively increase equipment life.

Environmental health: This product is made of environmentally friendly materials, does not contain harmful substances, and has no impact on the environment and human health.

Production process:

Material preparation: High-quality cotton materials are selected and strictly screened and tested to ensure that the material quality is stable and reliable.

Preparation of deformable adhesive: According to specific formulations, unique deformed adhesives are prepared to ensure that they can play a good role in different working environments.

Coating with deformed adhesive: The prepared deformation adhesive is applied to the surface of the cotton conveyor belt to ensure that the glue is evenly coated to avoid missed coating or waste.

Drying and curing: A cotton conveyor belt coated with deformed rubber is sent into the drying equipment. Drying and curing at high temperatures ensures that the deformed rubber can be fully cured to improve the durability and stability of the product.

Inspection packaging: After strict inspection and quality control, the product is packaged to ensure that the product is intact, and customized packaging and labeling are carried out according to customer needs.

Customer stories

Company name: A food company in the United States

Industry: Food processing

Product: Potato chips production line

Problem description:

This food company is a food processing plant that specializes in the production of potato chips. Their production line uses multiple conveyor belts to complete different processes. Due to continuous changes in the working environment and temperature in the production line, conventional conveyor belts often have problems such as deviations and jumps, which affect the stability and efficiency of the production line, and also increase the cost and difficulty of equipment maintenance.

Solution:

This food company sought our products and solutions. We introduced them to the double-sided modified cotton conveyor belt and customized it individually to the characteristics of their production line. We provided them with professional technical support and services to ensure the smooth installation and commissioning of the conveyor belt.

Evaluation of effects:

After using a double-sided modified cotton conveyor belt, the food company’s production line stability and efficiency were greatly improved. The conveyor belt can automatically adapt to different working environments, maintain smooth operation at all times, offset and jump phenomena are effectively controlled, and production efficiency has been significantly improved. At the same time, the lightweight, durable and environmentally friendly and healthy characteristics of the conveyor belt were also highly praised by customers.

The double-sided deformed cotton conveyor belt can be adapted to different environments mainly through its unique double-sided deformation design. Specifically, the surface of this conveyor belt is coated with a special layer of deformable adhesive. This adhesive has certain elasticity and deformation properties, and can automatically adjust its shape according to different environments and working conditions, thereby adapting to different transportation requirements.

The deformation adhesive for double-sided deformed cotton conveyor belts also has certain wear resistance and corrosion resistance, can maintain good service life and performance stability in different working environments, and reduce equipment maintenance costs and frequency.

The deformation adhesive of the double-sided modified cotton conveyor belt does not pollute the environment, because the deformation adhesive used in this product is an environmentally friendly material, does not contain harmful substances, and can be used in a healthy and environmentally friendly manner. Specifically, the rubber material is composed of various environmentally friendly materials such as natural rubber, environmentally friendly resins, additives, etc., does not contain any harmful substances or toxic components, meets international environmental standards, and does not cause any harm to the environment and human health.

During the production process, Shunsheng will adopt a series of environmental protection measures, such as strictly controlling the discharge of waste water, exhaust gas and waste residue to ensure that the production process does not pollute or damage the environment.

In short, the modified adhesive used in the double-sided cotton conveyor belt is an environmentally friendly material that does not pollute the environment. At the same time, the production process also takes a series of environmental protection measures to ensure the environmental protection and health of the product and meets the requirements and expectations of customers and society.