Product dimensions

Capsule stud pattern belt for wood processing provides a variety of size options. Common sizes are as follows:

- Width: 200 mm, 300 mm, 400 mm, 500 mm, 600 mm

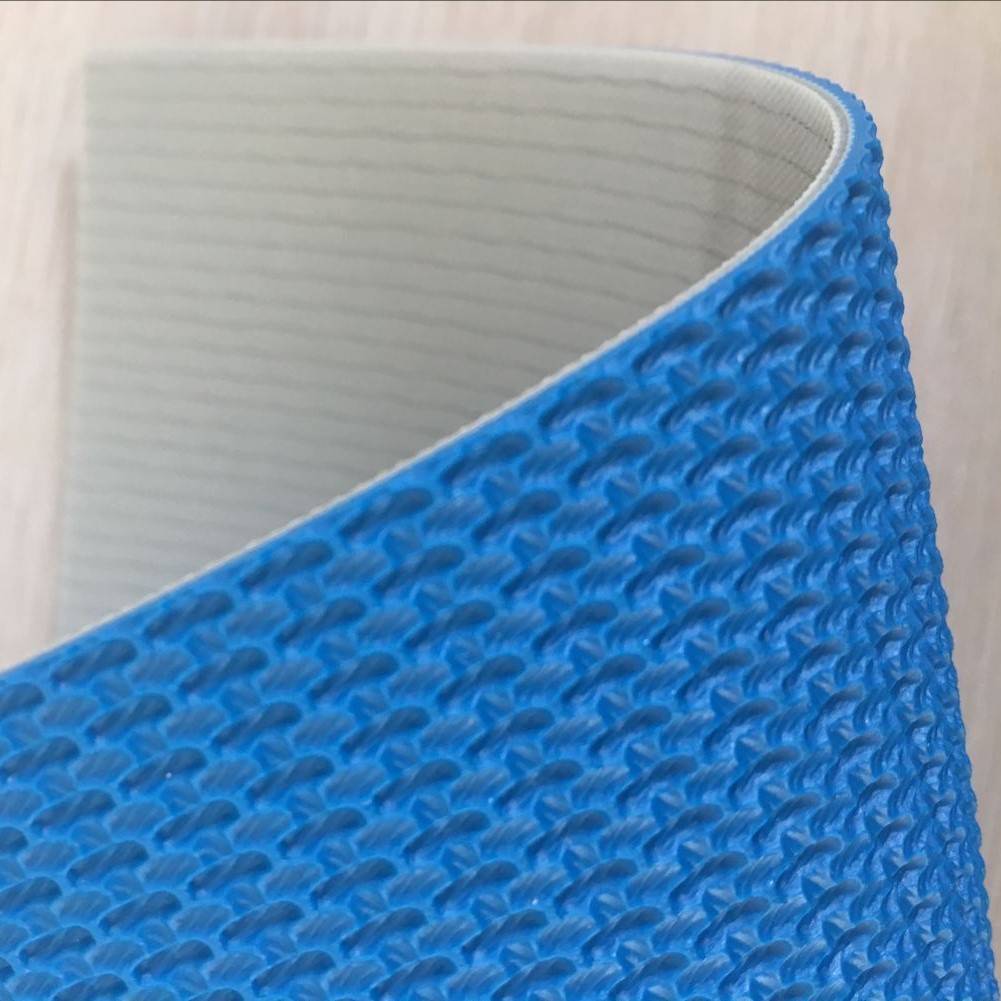

- Length: 1 meter, 2 meters, 3 meters, 4 meters, 5 meters (can be customized according to your needs)

Product characteristics

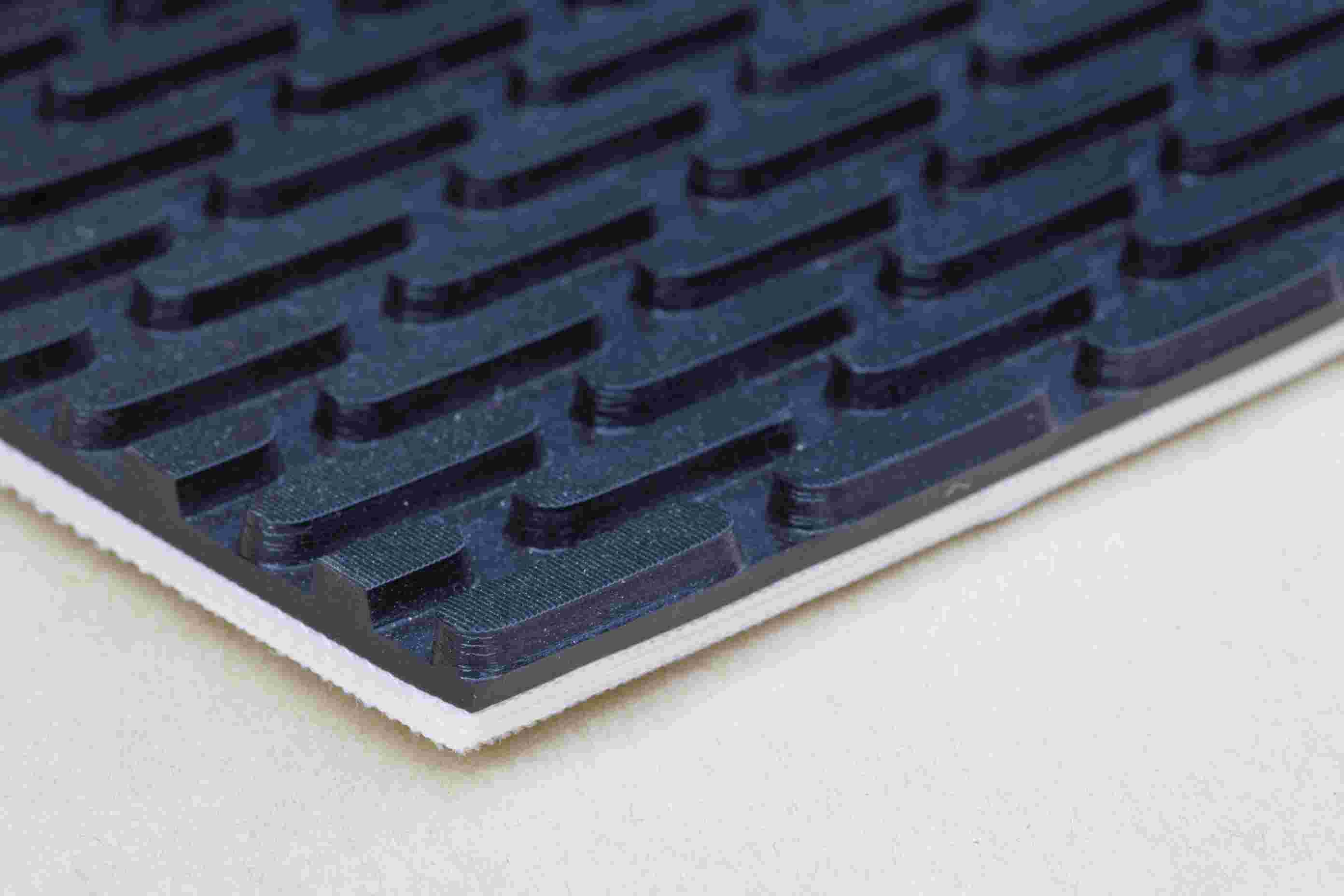

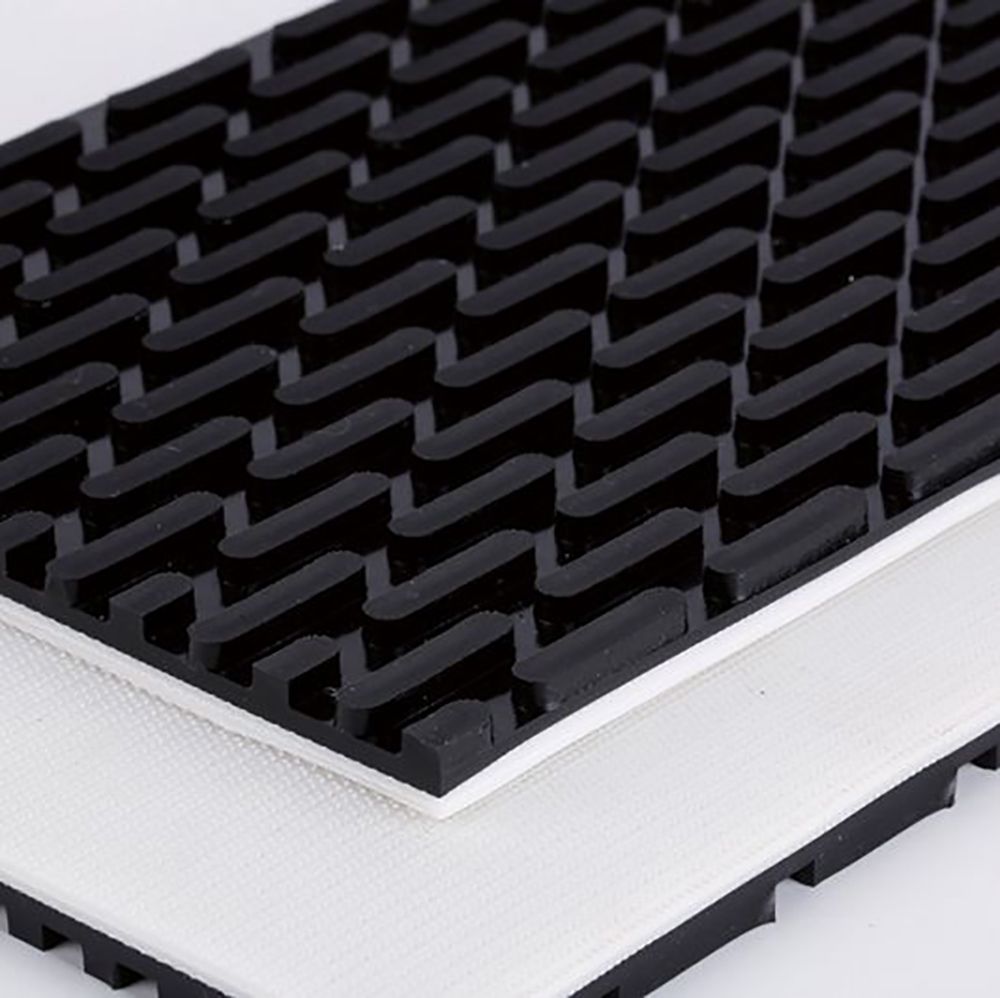

- Capsule nail pattern design: increases friction, ensures the stability of the material during transportation, and prevents slipping.

- High wear resistance: Using high quality materials, it has a long service life.

- High temperature resistance and low temperature resistance: suitable for various temperature environments.

- Save space: Lightweight design, takes up little space, easy to install and debug.

- Easy to clean: The surface is smooth and easy to clean, ensuring product hygiene.

Production process

- Conveyor belt substrate preparation: First, select suitable substrates, such as polyester, polyurethane, etc., and cut and process according to requirements.

- Capsule preparation: Materials such as polyester are made into a capsule shape and thermoformed by hot pressing.

- Nail pattern preparation: Materials such as metal are made into nail patterns and heat treated.

- Adhesion of the capsule, nail pattern and base material: The capsule and nail pattern are bonded to the conveyor belt substrate as required, usually fixed with glue or hot melt adhesive.

- Conveyor belt surface treatment: The surface of the conveyor belt is treated to make it non-slip, wear-resistant, etc.

- Inspection and packaging: The produced conveyor belt is inspected to ensure that its quality meets the requirements and is packaged.

Product advantages

- Precise conveying: The capsules and pegs on the surface of the conveyor belt can effectively prevent the material from slipping, so that the material can be conveyed accurately on the conveyor belt, thereby improving processing accuracy.

- Strong wear resistance: The surface of the conveyor belt uses a combination structure of capsules and nails, which can effectively resist wear and damage, thereby extending the service life.

- Strong load capacity: The combined design of the capsule and nail pattern makes the conveyor belt have a high carrying capacity and can withstand greater weight and pressure.

- Wide scope of application: The capsule conveyor belt for wood processing is suitable for various processing processes, such as food processing, pharmaceuticals, chemicals, electronics, etc.

- Easy installation: The conveyor belt is fixed with glue or hot melt glue, etc., and installation and replacement are convenient.

Application scenarios

- Food processing: including food processing such as meat, poultry, aquatic products, vegetables, pastries, etc., to ensure stable transmission of food on the production line.

- Packaging industry: Suitable for conveying all kinds of packaging materials, such as cartons, plastic trays, etc.

- Pharmaceutical industry: Ensuring accurate transmission of drugs on production lines and reducing cross-contamination.

- Electronics industry: Used for the transmission of electronic components, circuit boards and other products.

- Machining: Suitable for the transmission of parts, finished products and other materials during processing.

Installation and maintenance

Capsule stud pattern belt for wood processing is easy to install, and users can assemble according to actual requirements. The operating condition of the conveyor belt is checked regularly and necessary maintenance is carried out to ensure the stable operation of the equipment over a long period of time.

Customer service

Shunsheng provides customers with a full range of pre-sales and after-sales services, including product consultation, custom design, installation and commissioning. If you encounter any problems during use, please do not hesitate to contact us.

The service life of capsule stud pattern belt for wood processing is affected by many factors, including the usage environment, material quality, frequency of use, and maintenance.

Under normal use, the conveyor belt is properly cared for and maintained, and its service life can reach several years to more than ten years. However, if the use environment is harsh, such as high temperatures, high humidity, corrosive gases, etc., the service life may be shortened.

The frequency of use affects the service life of the conveyor belt. If the frequency of use is high, the degree of wear of the conveyor belt will increase accordingly, thereby reducing the service life.