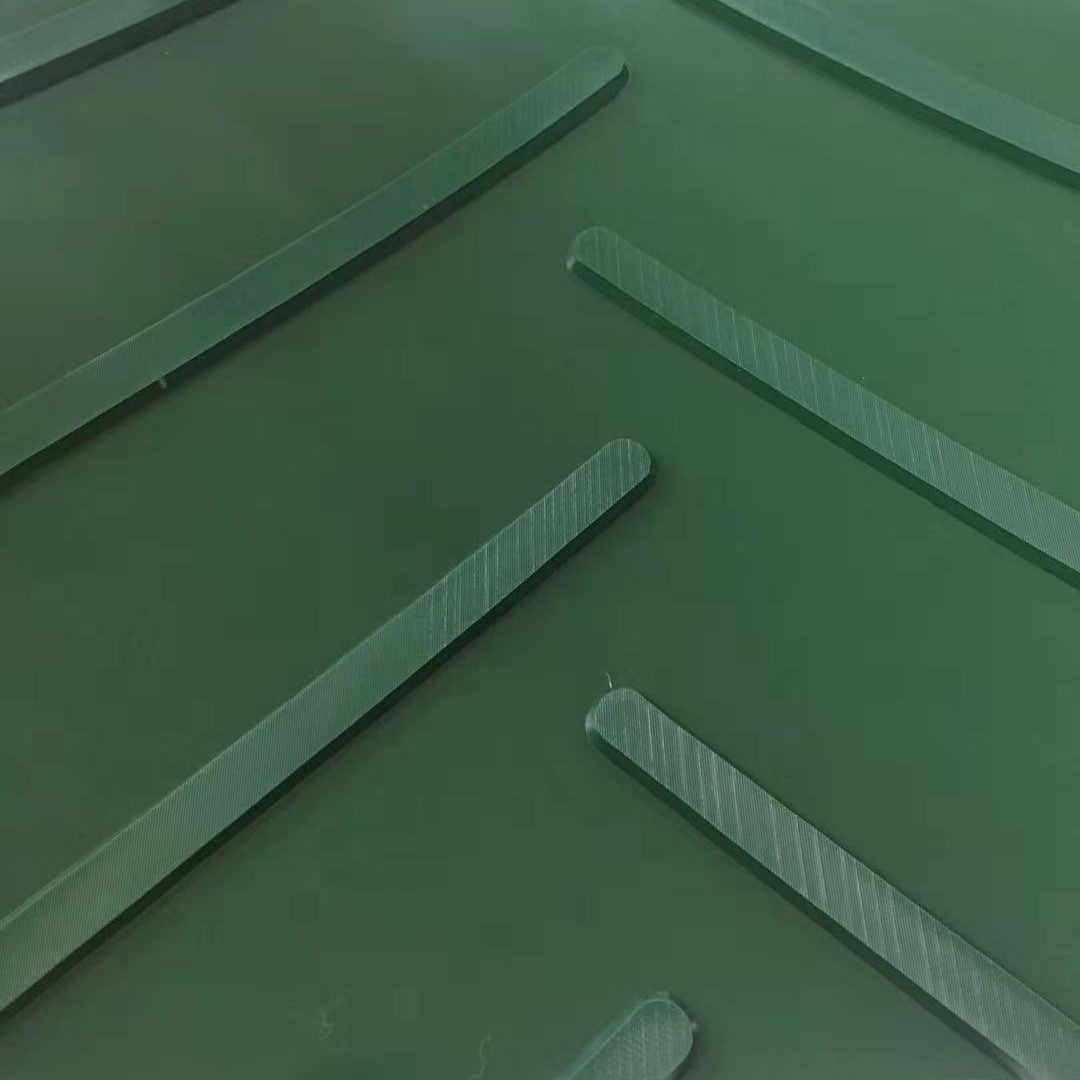

Big Star RGared Herringbone Pattern Belts for Agriculture Features

- Herringbone design: The surface of our agricultural conveyor belt uses a unique herringbone pattern design, which not only increases friction and reduces the risk of materials slipping, but also maintains good grip in wet and slippery environments to ensure smooth transportation of materials.

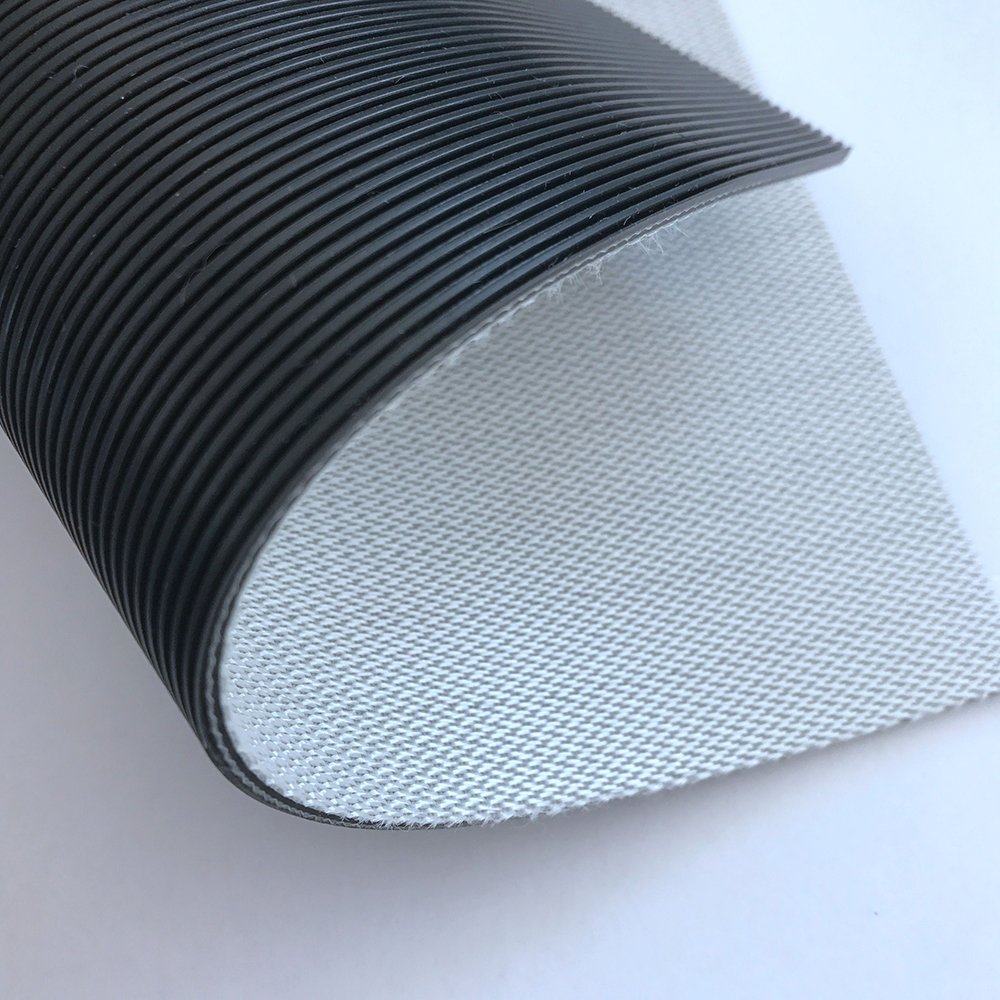

- Environmentally friendly materials: This conveyor belt is made of environmentally friendly rubber, is non-toxic and odorless, and meets environmental standards in countries around the world, so you don’t need to worry about the impact on the environment and human health during use.

- High wear resistance: Our products have high wear resistance, can withstand long periods of friction, prolong service life, thereby reducing costs.

- Strong load capacity: After careful design and manufacture, this conveyor belt has a high load capacity and can meet the transportation needs of various agricultural materials.

Application scenarios

Big starrgared herringbone pattern belts for agriculture are widely used in various fields of agricultural production:

- Grain transportation: Conveyors can move grains quickly and efficiently from one place to another during harvesting, processing, and storage.

- Fruit and vegetable sorting: For fruit and vegetable processing plants, conveyor belts can help quickly sort and transport different fruits and vegetables to improve work efficiency.

- Animal husbandry: In feed processing, transportation and excrement treatment, conveyor belts can improve work efficiency and reduce labor intensity.

- Fertilizer application: In agricultural production, the transportation and application of fertilizer is an essential part, and PVC agricultural conveyors can help apply fertilizer to fields faster and more accurately.

Maintenance method

- Regular inspection: Regularly check the surface of the conveyor belt for wear, tear, cracks, deformation, etc. If problems are found, fix or replace them promptly.

- Clean the conveyor belt: Clean the surface of the conveyor belt regularly to prevent dust, dirt, grease and other substances from accumulating on the surface and affecting the service life of the conveyor belt.

- Maintain proper humidity: Agricultural conveyors should maintain proper humidity during storage and use to prevent the surface from drying out or moisture and mold.

- Avoid excessive stretching: You should avoid excessive stretching of the conveyor belt during use, as this can cause the belt to loosen, break, or break.

- Proper use: When using a conveyor belt, you should avoid using excessive loads or speeds, which can cause the belt to wear or damage.

- Regular lubrication: Regularly lubricate the conveyor belt’s rollers and bearings to reduce wear and friction.

Cleaning method

- Use mild cleaners: Use mild cleaners or soapy water and avoid acidic or alkaline cleaners, as these may damage the surface of the conveyor belt.

- Avoid over-cleaning: Avoid over-cleaning the conveyor belt surface, as excessive cleaning may cause the surface to dry and crack.

- Choose the right cleaning tool: Use a soft brush or sponge to clean the surface of the conveyor belt and avoid using hard or sharp objects to avoid scratching the surface.

- Regular cleaning: Clean the surface of the conveyor belt regularly to prevent dust, dirt, grease and other substances from accumulating on the surface and affecting the service life of the conveyor belt.

- Pollution prevention: The conveyor belt should avoid contact with substances such as grease, chemicals, etc. during use to prevent pollution and wear.

- Keep it dry: After cleaning the surface of the conveyor belt, you should dry it as soon as possible and keep it dry to prevent the surface from getting wet or moldy.

Cleaning Precautions

Develop a cleaning plan based on usage: Develop an appropriate cleaning plan based on how the conveyor belt is being used. Generally speaking, the frequency of cleaning should be determined based on how often the conveyor belt is used, the environment, and material accumulation.

Choose the right time: Choose the right time to clean to avoid disrupting production during peak periods or production processes.

Conduct a safety check before cleaning: Before cleaning the conveyor belt, you should check that the equipment has stopped working and that the safety switch is off to ensure the safety of workers.

Remove dirt and debris: Use tools such as brushes, vacuum cleaners, or air pressure cleaners to clean the conveyor belt surface of dirt and debris.

Check the surface of the conveyor belt: During the cleaning process, the surface of the conveyor belt should be carefully examined for wear, tear, cracks, deformation, etc. If problems are found, fix or replace them promptly.

Regular lubrication: When cleaning the rollers and bearings of the conveyor belt, they should be lubricated regularly to reduce wear and friction.