Product introduction:

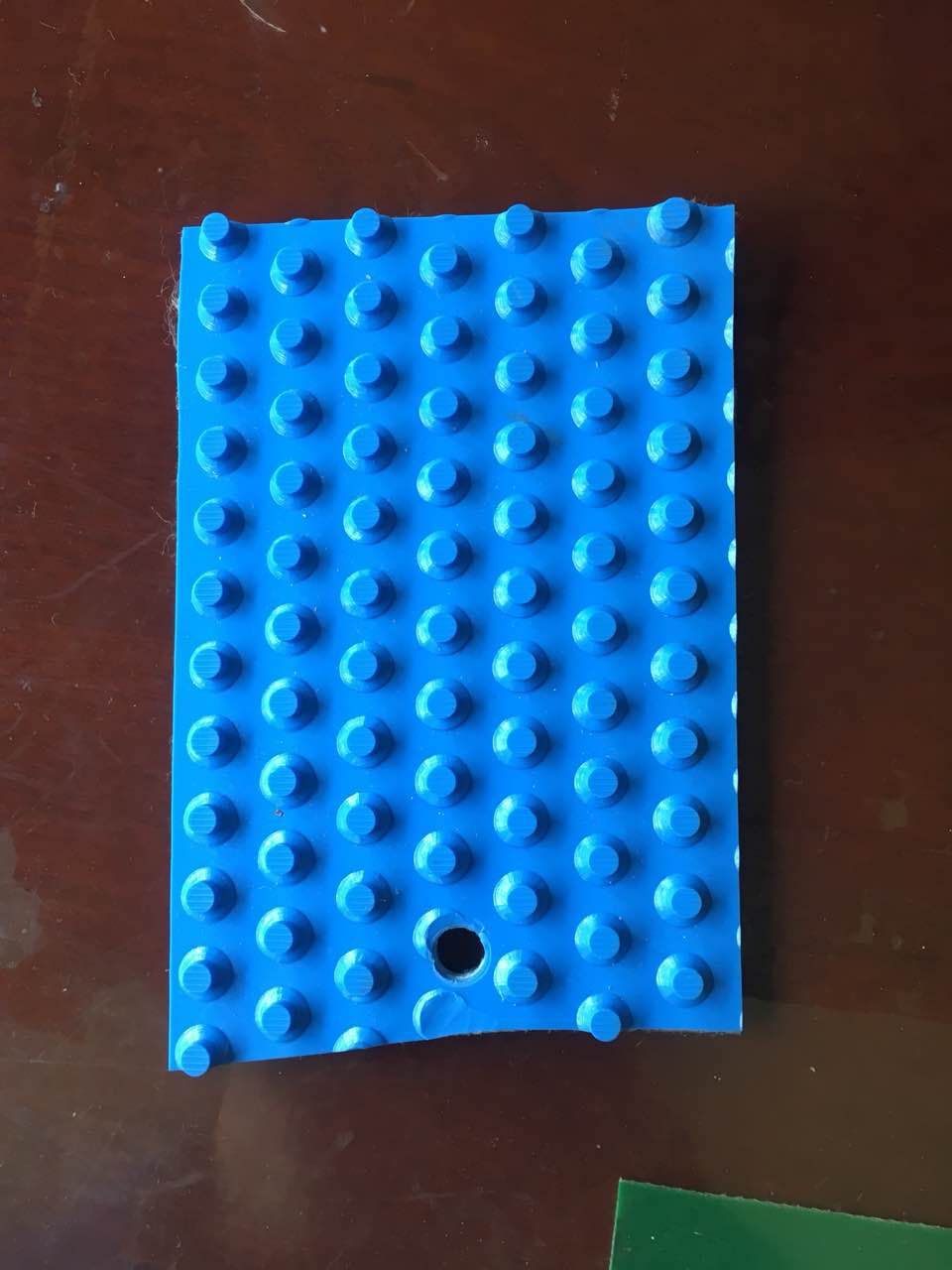

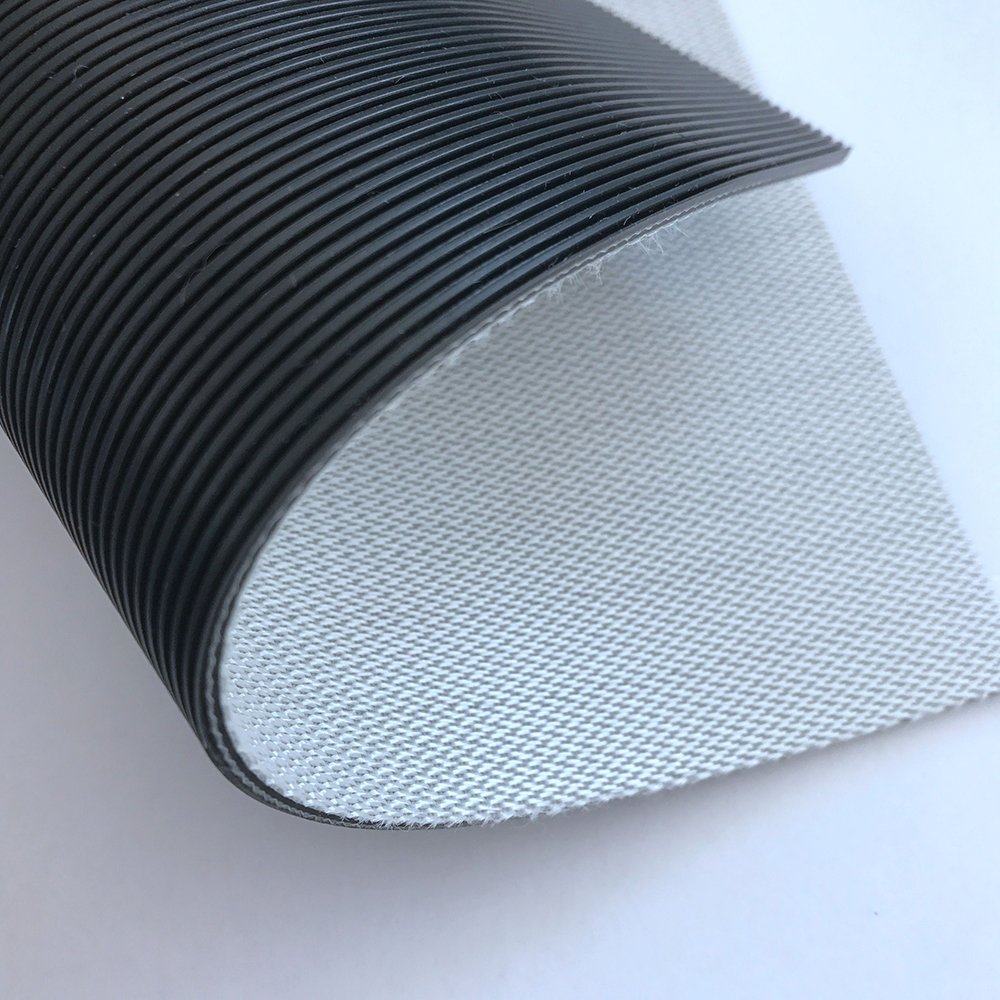

Big nipple pattern conveyor belt for conveyor industry is a professional conveyor belt for agricultural machinery transmission. It is made of high-quality rubber materials and has a large nipple pattern on the surface, which can effectively improve the friction of the conveyor belt and ensure the stability and safety of material transportation.

Product features:

- High strength: Agricultural large nipple pattern conveyor belts are made of high-quality rubber materials, have high tensile strength and wear resistance, and can meet the transmission requirements of different agricultural machinery.

- Large nipple pattern: The surface of the product has a large nipple pattern, which can increase the friction between the conveyor belt and the material, prevent sliding and slipping, and improve the transmission efficiency and safety of the conveyor belt.

- Good weather resistance: Big nipple pattern conveyor belt for flooring industry has good weather resistance and aging resistance, and can adapt to the requirements of use in different climates and environmental conditions.

- Easy installation: The product is easy to install and can be customized according to the transmission requirements of agricultural machinery to improve the efficiency of use.

Instructions for use:

Agricultural large nipple patterned conveyor belts should be inspected before use to ensure that there are no obvious damage or cracks on the surface of the conveyor belt.

Overload and overspeed should be avoided during use to avoid damage to the conveyor belt.

Care should be taken to adjust the tension of the conveyor belt during use to ensure transmission efficiency and safety.

During use, the wear of the conveyor belt should be checked regularly, and damaged parts should be replaced in a timely manner to extend the service life of the conveyor belt.

Daily maintenance:

Clean the surface of the conveyor belt regularly to keep the conveyor belt clean and sanitary.

Check the tension of the conveyor belt and make timely adjustments.

Regularly lubricate the bearings and transmission components of the conveyor belt to ensure the normal operation of the conveyor belt.

Check and resolve common problems:

The conveyor belt is slippery: check whether the tension of the conveyor belt is appropriate and adjust the tension of the conveyor belt.

Abnormal noise in the conveyor belt: check whether the transmission parts of the conveyor belt are loose or worn, and replace or fasten the transmission parts promptly.

The surface of the conveyor belt is cracked: replace the conveyor belt.

Shunsheng provides you with high-quality products and perfect after-sales service, hoping to meet the needs of all kinds of customers and establish long-term stable cooperative relationships.

Customer stories

Case 1: Orchard Transportation

In order to improve the transportation efficiency and safety of fruit, an orchard chose to use an agricultural large nipple patterned conveyor belt to transport the fruit from within the orchard to the packaging workshop. The large nipple pattern can effectively increase the friction between the conveyor belt and the fruit, prevent the fruit from falling, and improve transportation efficiency and safety.

Case 2: Feed production

In order to improve production efficiency and product quality, a feed manufacturer chose to use Shunsheng’s conveyor belt to transport raw materials from the warehouse to the production workshop. The large nipple pattern can improve the transmission efficiency and stability of the conveyor belt, speed up the transportation speed of raw materials, and improve production efficiency.

Case 3: Agricultural machinery

In order to improve the quality and reliability of its products, an agricultural machinery manufacturer chose to use agricultural large nipple patterned conveyor belts as transmission components for its products. Large nipple patterns can improve transmission efficiency and stability, reduce failure rates, and improve the reliability and longevity of agricultural machinery.

Case 4: wood processing

In order to improve production efficiency and product quality, a wood processing company chose to use agricultural large nipple patterned conveyor belts to transport wood from the warehouse to the processing workshop. The large nipple pattern can improve the friction between the conveyor belt and the wood, prevent sliding and slipping, and improve the transmission efficiency and safety of the conveyor belt.

Case 5: Farmers’ Market

In order to improve the operating efficiency of the market and customer satisfaction, a farmers’ market chose to use large nipple patterned agricultural conveyor belts to transport goods from the warehouse to the sales area. Very satisfied with the operation of the conveyor belt.