Product characteristics

Energy efficient: Advanced air cooling technology is used to save energy and reduce operating costs.

High temperature accuracy: Using high-efficiency heating elements, it can heat up quickly, has high accuracy and good temperature stability, and is suitable for high-precision heating.

Safe and reliable: Using safe and reliable heating elements and control systems, it has multiple safety protection measures such as overload protection and overheating protection to ensure the safe and stable operation of the equipment.

Easy to operate: Using an advanced control system, the operation is simple and convenient, and the temperature and time can be set as needed.

Environmental protection and energy saving: Using air cooling technology, no water source is required, no pollution, and meets environmental requirements.

Product specifications

- Heating power: 1kw-100kw optional

- Heating temperature: room temperature -600 ℃

- Heating method: air cooling

- Control method: PID digital control

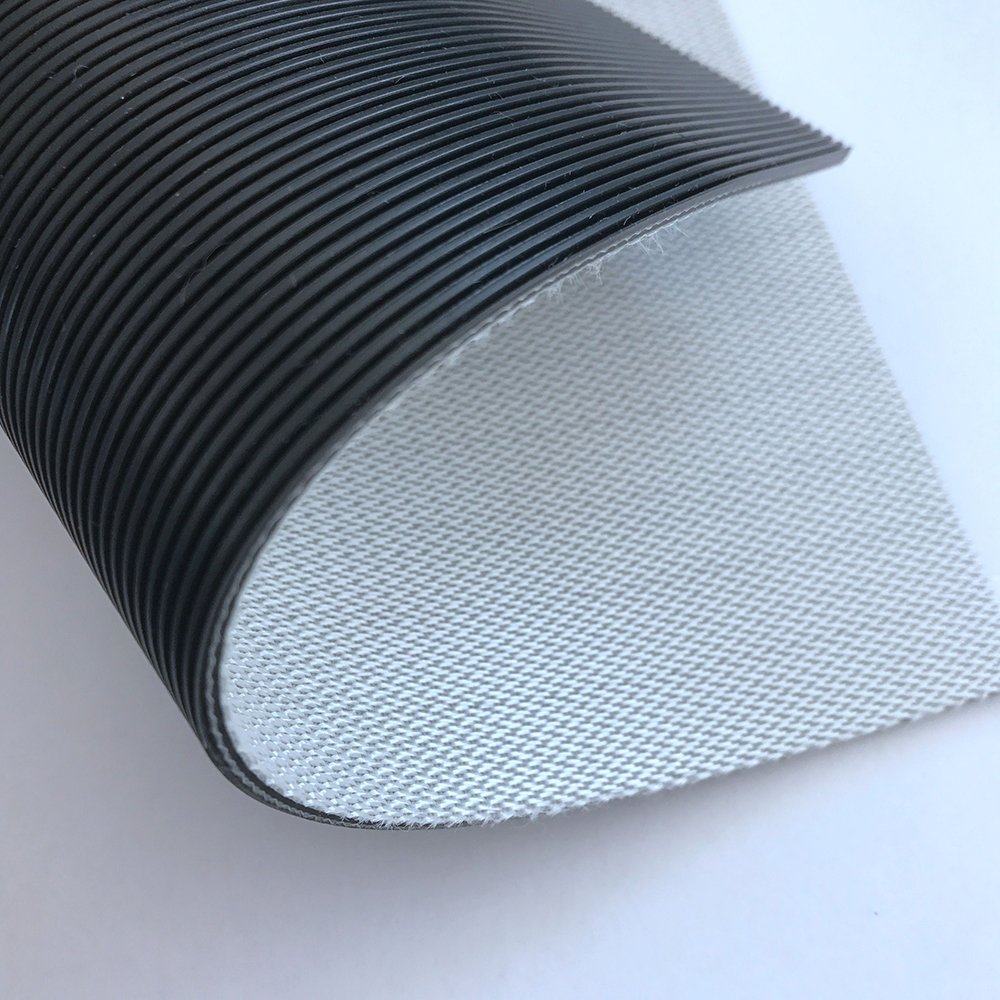

- Heating element: high efficiency heating tube

- Power supply: 220V/380V optional

Precautions for use

Do not place the device in a humid, explosive, flammable, or corrosive gas environment.

Do not disassemble or replace internal components of the device without permission.

Please check whether the equipment is working properly before operation to avoid equipment failure due to lack of inspection.

Please do not touch the surface of the device during operation to avoid burns.

When the equipment is not used for a long time, please cut off the power supply and perform regular maintenance.

Please do not overload the device during use to avoid damage to the equipment or affect the life of the equipment.

Please pay attention to whether the power supply voltage and frequency of the device match the local power grid to avoid damage to the equipment or safety accidents.

When the equipment is in operation, do not store flammable or explosive items near the device to avoid a fire accident.

During the operation of the equipment, if you find any abnormalities in the equipment, please immediately cut off the power supply and contact a professional for maintenance.

During the operation of the equipment, do not change the control parameters of the equipment at will, so as not to affect the operating effect and safety of the equipment.

Repairs and maintenance

Before operating the equipment, check whether the exterior of the equipment is clean and whether there are any debris inside. If so, please clean it up promptly.

Regularly check whether the working power supply and wires of the equipment are normal, and whether the power plug and socket are in good contact. If there are any problems, please replace them promptly.

Check whether the heating element of the device is damaged or old, and if there is a problem, please replace it promptly.

Check whether the control system of the equipment is normal, and whether the control panel, thermometer, timer, etc. are damaged or old. If there are any problems, please replace them promptly.

Regularly check whether the cooling system of the equipment is normal, clean the radiator and fan, and ensure that the cooling effect of the equipment is good.

Change the filter of the equipment regularly to ensure that the ventilation performance of the equipment is good.

Regularly check the operating condition of the equipment, and adjust or replace parts in a timely manner if equipment abnormalities are found.

Regularly check whether the safety measures of the equipment are perfect, such as safety switches, leakage protectors, etc., are normal.

Maintain the hygiene of the equipment by cleaning and disinfecting it regularly.

Regularly lubricate the equipment to keep the equipment running normally.

After-sales service

A one-year free warranty service is provided, and products that have exceeded the warranty period are provided with a lifetime maintenance service.

Provide after-sales technical support and consulting services to answer customer questions and problems in a timely manner.

Provide equipment installation, commissioning, training and maintenance services to ensure the normal operation and stability of the equipment.

Contact information

If you have any questions about air cooling and hot connectors or need to buy products, please contact us:

Contact person: Mr. Zhang

Tel: +86-510-83312052

Email: [email protected]

Thank you for choosing our products, we will be happy to help you!