It is an indispensable and important tool, widely used in the handling, processing and assembly of various materials. Among the many conveyor belt materials, TPU (thermoplastic polyurethane) conveyor belt has gradually become the preferred equipment for modern production lines with its unique performance advantages. So, what are the characteristics and advantages of TPU 컨베이어 벨트, and why can it become a “new favorite” that stands out in the industry?

TPU conveyor belt: a new material choice

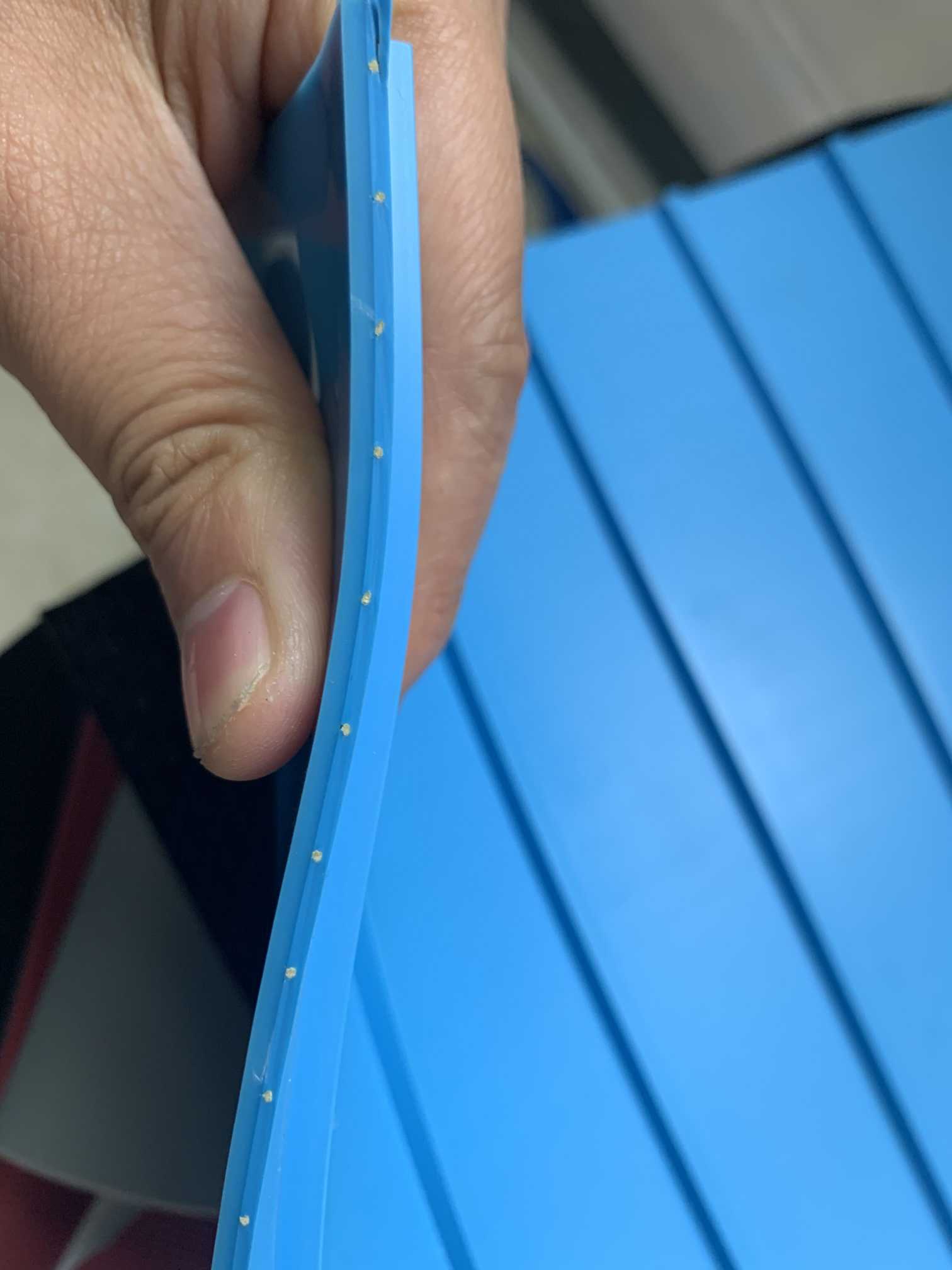

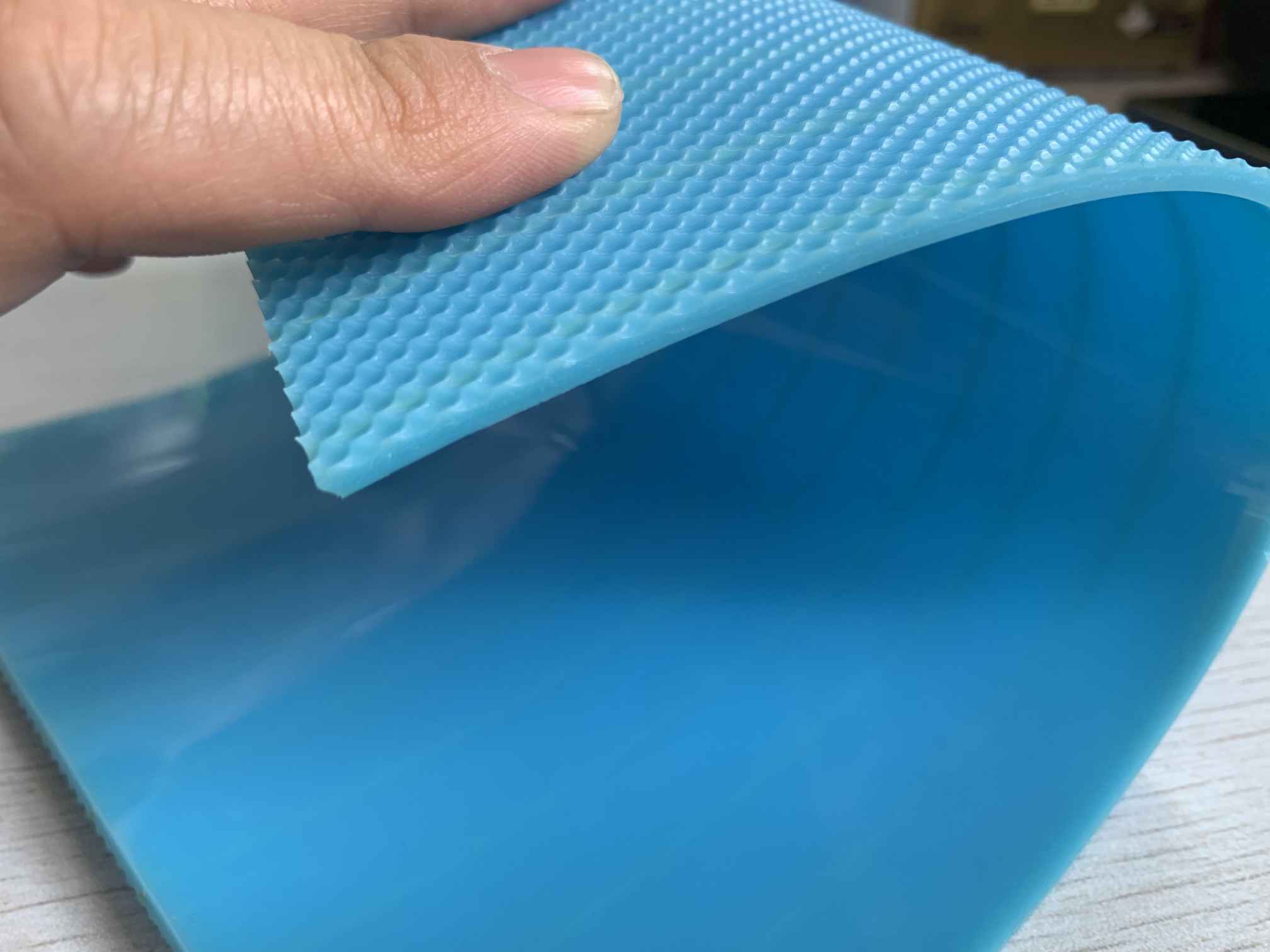

TPU conveyor belt, as the name suggests, is a conveyor belt based on thermoplastic polyurethane (TPU). As a thermoplastic elastomer, TPU has good formability and processability, can maintain flexibility at high temperatures, and has extremely high hardness and strength after cooling, showing excellent mechanical properties. Compared with traditional rubber and PVC conveyor belts, TPU conveyor belts not only have stronger wear resistance, but also can adapt to more complex and changeable production environments. Nowadays, more and more industries are beginning to choose TPU conveyor belts to meet the transportation needs under high strength, high load and special working conditions.

Unique advantages of TPU conveyor belts

Excellent wear resistance and long life

In heavy-load, high-frequency industrial environments, the wear resistance of conveyor belts is crucial. With its excellent wear resistance, TPU conveyor belts can maintain good working conditions during long-term operation and extend the service life of equipment. Compared with traditional rubber conveyor belts, TPU conveyor belts show lower wear rates during high-speed operation, thereby reducing the company’s maintenance costs and downtime.

Excellent chemical corrosion resistance

TPU materials have good chemical corrosion resistance and can resist the erosion of oils, acids, alkalis and solvents. This feature makes TPU conveyor belts an ideal choice in industries such as chemical, pharmaceutical and food processing. In these industries, conveyor belts not only need to withstand the transportation of heavy objects, but also need to avoid any leakage or contamination of chemicals, and TPU just solves this problem.

Excellent high and low temperature resistance

TPU materials can still maintain stable performance in an environment with changing temperatures. Whether it is a high or low temperature working environment, TPU conveyor belts can adapt freely. This feature ensures that TPU conveyor belts can maintain their continuous high-efficiency performance in high-temperature workshops, cold chain logistics or extremely cold environments, and are widely used in refrigeration, heating, drying and other process links.

Environmentally friendly and pollution-free, green and recyclable

In the context of global advocacy of green and environmentally friendly production, TPU, as a non-toxic and pollution-free material, fully meets environmental protection requirements. No harmful substances are used in the production process of TPU conveyor belts, and they can be recycled and reused after being discarded. This not only meets the requirements of environmental protection policies, but also helps companies reduce the risk of environmental pollution.

High load-bearing capacity, adaptable to heavy-load transportation

The load-bearing capacity of TPU conveyor belts far exceeds that of many traditional materials, and can easily cope with the transportation needs of heavy and complex materials. Its excellent tensile strength enables it to maintain stability and durability when transporting bulk goods. This makes TPU conveyor belts widely used in high-intensity and high-load environments such as mining and construction.

Wide application fields of TPU conveyor belts

With its many advantages, TPU conveyor belts have been widely used in many industries, especially in those industries that have high requirements for conveyor belt performance. The following are the main application areas of TPU conveyor belts:

Food processing industry

The food industry has extremely high requirements for the hygiene and safety of the production environment. TPU conveyor belts meet food grade standards and are easy to clean. They can effectively prevent food contamination and ensure the safety of the production process. Whether it is the washing and packaging of fruits and vegetables, or the production of beverages and candies, TPU conveyor belts can provide stable and reliable support.

Pharmaceutical industry

The pharmaceutical industry requires conveyor belts to not only meet hygiene standards, but also have good resistance to chemical corrosion. The non-toxic and pollution-free characteristics of TPU conveyor belts make it an ideal conveying material for pharmaceutical companies. It is widely used in the production, packaging and material handling of medicines to ensure that every link meets strict quality control requirements.

Electronic manufacturing industry

In the electronics industry, the production process requires high-precision and high-stability equipment to ensure product quality. The smooth operation and wear-resistant characteristics of TPU conveyor belts ensure the safety of electronic components during transportation and avoid component damage caused by excessive friction or unstable transportation. Therefore, TPU conveyor belts play a vital role in the assembly and handling of electronic products.

Logistics and automated packaging industry

In modern logistics and automated packaging production lines, TPU conveyor belts have become the core part of automated conveying systems with their high load-bearing capacity and stability. It can easily handle the transportation of items of various weights and sizes, and is widely used in e-commerce logistics, express sorting, warehousing and distribution, etc., improving production efficiency and reducing labor costs.

Mining and metallurgical industry

In the mining and metallurgical industry, the handling of materials often needs to face extremely complex working environments, such as high temperature, heavy load, chemical corrosion, etc. The high strength, high temperature resistance and corrosion resistance of TPU conveyor belts meet the transportation needs under these harsh working conditions and are widely used in the transportation of materials such as ore, coal, and steel.

Why choose TPU conveyor belts?

Among many conveyor belt materials, TPU has gradually stood out with its comprehensive advantages and has become a new favorite in various industries. Enterprises choose TPU conveyor belts not only because of its superior physical and chemical properties, but also because it can reduce maintenance frequency and reduce production costs during long-term use. Especially in high-intensity, high-load and complex environments, TPU conveyor belts perform particularly well, meeting the specific needs of different industries.

In addition, as companies pay more attention to environmental protection and sustainable development, TPU conveyor belts have been favored by more and more companies because of their environmentally friendly, pollution-free and recyclable characteristics. By choosing TPU conveyor belts, companies can not only improve production efficiency and reduce energy consumption, but also reduce the negative impact on the environment and achieve green production.

TPU conveyor belts are gradually changing the production methods of various industries with their remarkable characteristics such as wear resistance, high and low temperature resistance, and corrosion resistance. From food processing to mining and metallurgy, from electronic manufacturing to logistics and transportation, TPU conveyor belts are becoming an indispensable key equipment in modern industrial production due to their excellent performance. For companies, investing in TPU conveyor belts is not only a wise choice to improve productivity, but also an inevitable path to sustainable development. With the continuous advancement of technology, the application prospects of TPU conveyor belts will be broader, providing strong support for the transformation and upgrading of the global manufacturing industry.