Introduction

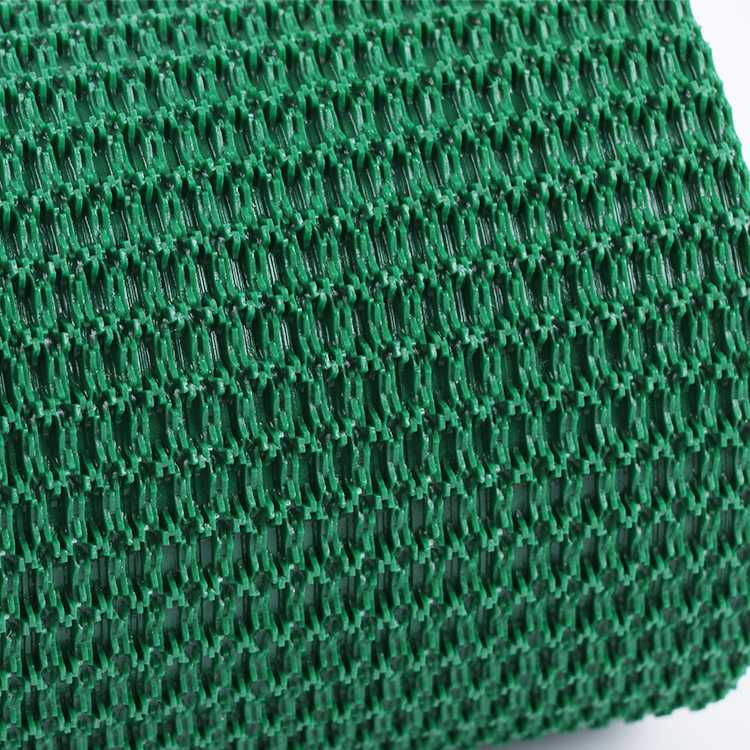

PVC green conveyor belts are integral components in a wide range of industries, facilitating the smooth movement of goods and materials. The performance and reliability of these conveyor belts are paramount for businesses. In this article, we will explore the crucial aspects of product quality, durability, and compliance with industry standards and regulations as maintained by your PVC green conveyor belt supplier.

Product Quality Assurance

The quality of PVC green conveyor belts is non-negotiable. To ensure the belts’ reliability and consistent performance, it is imperative to understand how your PVC green conveyor belt supplier maintains product quality.

- Explanation of the Supplier’s Methods

Reputable PVC green conveyor belt suppliers implement robust quality assurance procedures. This includes:

Quality Control Procedures During Manufacturing

From the moment raw materials are sourced, through the manufacturing process, to the final inspection, there are stringent quality control measures in place. These measures help in detecting and rectifying any deviations from the specified quality standards.

Testing and Inspection Protocols

The belts undergo thorough testing and inspection at various stages of production. This can involve tests for tensile strength, elongation, thickness, and visual inspections to identify any defects or irregularities.

- Role of Product Quality in Ensuring Reliability

Quality control is not merely a procedural necessity; it ensures the end product’s reliability and consistency. A conveyor belt’s quality directly correlates with its longevity, minimizing downtimes, and ensuring smooth operations.

Durability and Longevity

PVC green conveyor belts need to be designed for durability, given the rigorous conditions they often work in.

- Design Elements for Durability

The supplier’s design choices are pivotal for ensuring the longevity of PVC green conveyor belts. Key considerations include:

Choice of Materials and Construction

Selecting high-quality PVC compounds and robust construction methods is essential. This ensures that the belt can withstand heavy loads, resist wear and tear, and endure various operating conditions.

Resistance to Wear, Impact, and Environmental Factors

Conveyor belts are exposed to a variety of stresses, including abrasion, impact, and exposure to environmental elements. The supplier’s commitment to designing belts that withstand these factors is crucial for durability.

- Supplier’s Contribution to Longevity

A reputable PVC green conveyor belt supplier doesn’t just provide conveyor belts; they provide solutions that can perform optimally for extended periods. Through superior design, material selection, and manufacturing processes, a PVC green conveyor belt supplier significantly contributes to the long-term reliability of the product.

Compliance with Industry Standards

Adherence to industry standards and regulations is vital, especially when conveyor belts are employed in sectors with strict safety and quality requirements.

- Description of the Supplier’s Commitment to Compliance

Your PVC green conveyor belt supplier should demonstrate a strong commitment to meeting industry-specific standards and adhering to relevant regulations. This commitment may encompass:

Specific Standards and Certifications

Different industries have their own unique standards. For instance, the food industry often requires FDA compliance for conveyor belts used in food handling, while ISO certifications may be essential for quality management. Knowing your supplier’s compliance with these standards ensures that the belts are suitable for your specific application.

Adherence to Safety and Environmental Regulations

Safety and environmental regulations are paramount, particularly in industries where conveyor belts are used. Understanding how your PVC green conveyor belt supplier complies with these regulations is essential for both safety and sustainability.

- Importance of Industry Compliance for Customers

Industry compliance not only ensures that your conveyor belts are fit for purpose but also protects your business from potential legal and safety issues. It’s crucial for customers to have confidence that their chosen PVC green conveyor belt supplier upholds these standards.

Quality Control and Testing Procedures

Behind every quality product is a series of stringent quality control and testing procedures.

- Insights into Quality Control and Testing Procedures

The specifics of these procedures can vary from one supplier to another. Understanding the processes your PVC green conveyor belt supplier employs gives you an insight into their dedication to delivering reliable conveyor belts.

- Verification Methods for Product Quality and Compliance

Your PVC green conveyor belt supplier will employ various verification methods to ensure product quality and compliance with standards. It is important for customers to have transparency in understanding these methods and their outcomes.

Conclusion

In the world of PVC green conveyor belts, product quality, durability, and industry compliance are non-negotiable factors. The supplier’s commitment to these aspects is a reflection of their dedication to customer satisfaction and reliability. By thoroughly evaluating your supplier’s practices in quality assurance, durability, and compliance, you can be confident in the performance and longevity of your PVC green conveyor belts. In an industry where downtime can be costly, choosing a PVC green conveyor belt supplier with a strong focus on these factors ensures seamless operations and peace of mind for your business.