Introduction

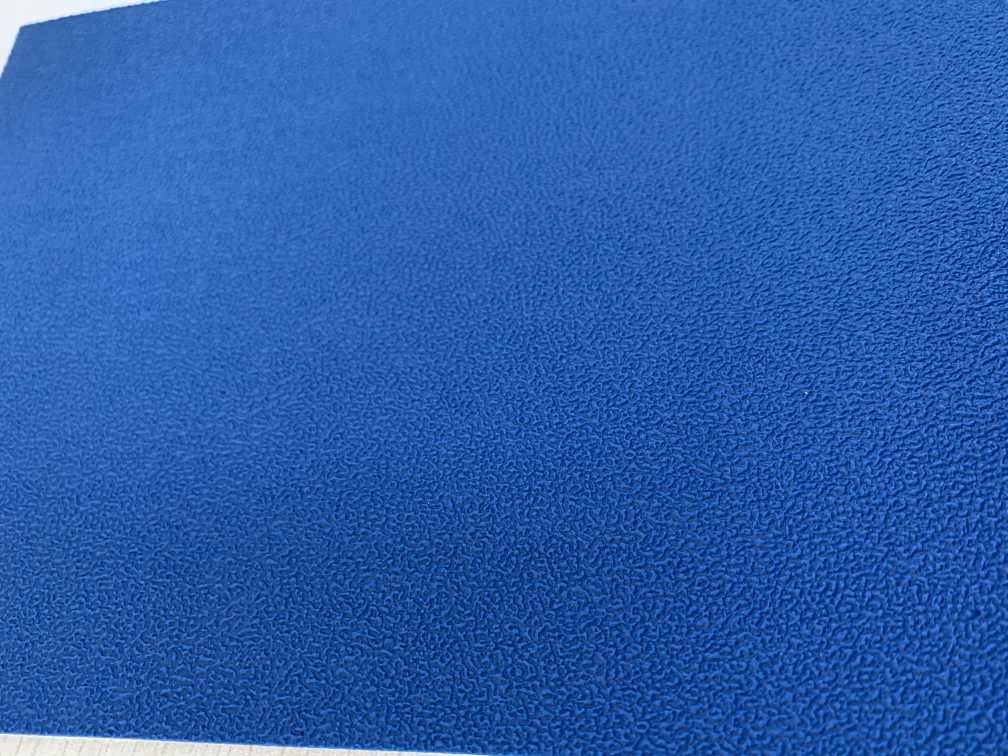

In the dynamic landscape of modern warehouses and distribution centers, the seamless movement of goods is integral to operational success. At the heart of efficient material handling systems lies the innovation and reliability of PVK logistics conveyor belts. Specifically, Polyvinyl Ketone (PVK) logistics conveyor belts have emerged as a cornerstone, significantly contributing to both the safety and efficiency of material handling processes within warehouses.

Safety Features of PVK Logistics Conveyor Belts

The paramount importance of safety in warehouse operations cannot be overstated. PVK logistics conveyor belts are engineered with specific safety features that address critical concerns:

PVK’s resistance to abrasion and wear ensures durability in environments where materials might otherwise cause damage. This feature not only extends the lifespan of the belt but also reduces the risk of debris, ensuring a safer working environment for warehouse personnel.

Moreover, the impact resistance of PVK belts is crucial in preventing damage due to sudden shocks or impacts, safeguarding both the conveyor system and the materials being transported.

Chemical and moisture resistance inherent in PVK material enhances safety by preventing the degradation of the belts when exposed to corrosive substances or moisture, reducing the likelihood of accidents or malfunctions.

PVK’s reduced stretching and elongation under heavy loads not only contribute to its longevity but also reduce the risk of unexpected belt failures, enhancing overall safety in warehouse operations.

Efficiency Enhancement through PVK Logistics Conveyor Belts

Efficiency is equally critical in warehouse settings, where streamlined operations directly impact productivity:

The speed and consistency in material transport facilitated by PVK logistics conveyor belts significantly contribute to operational efficiency. They ensure a steady flow of goods, reducing bottlenecks and optimizing throughput.

PVK belts require less downtime and maintenance due to their durable nature, leading to increased operational uptime and reduced disruptions in material handling processes.

Customizability is another factor contributing to efficiency. PVK belts can be tailored to fit various warehouse configurations, optimizing space utilization and material flow, ultimately enhancing overall operational efficiency.

Safety and Efficiency Synergy in Warehouse Material Handling

The interplay between safety features and operational efficiency is where PVK logistics conveyor belts truly shine:

Enhanced safety directly correlates with improved efficiency. A safer work environment leads to heightened employee morale and productivity, positively impacting the overall efficiency of warehouse operations.

Examples and case studies demonstrate how PVK logistics conveyor belts simultaneously ensure safety and enhance efficiency. In various industries, these belts contribute to improved work environments, streamlined material flow, and minimized product damage, showcasing their dual benefits.

Challenges and Considerations in Implementing PVK Logistics Conveyor Belts

Despite their numerous advantages, implementing PVK logistics conveyor belts comes with certain considerations:

Regular maintenance and care are crucial for prolonged safety and efficiency. Proper cleaning, tensioning, and lubrication are essential to ensure the belts operate optimally, reducing the risk of unexpected failures.

Cost and investment considerations need to be weighed against the long-term benefits. While PVK belts might have higher upfront costs, their extended lifespan and reduced maintenance requirements often result in cost savings over time.

Integration and adaptation of PVK logistics conveyor belts to specific warehouse environments might pose challenges. Tailoring the belts to fit unique configurations and operational requirements requires careful planning and expertise.

Future Prospects and Innovations in PVK Conveyor Belt Technology

Looking ahead, innovations in PVK conveyor belt technology promise further advancements:

Emerging trends indicate a focus on enhancing safety features and operational efficiency. Manufacturers are continually exploring new materials and technologies to improve conveyor belt performance in warehouses.

Potential developments, such as advanced sensors and monitoring systems integrated into PVK belts, offer insights into belt health and performance in real-time, further optimizing safety and efficiency.

Conclusion

In conclusion, PVK logistics conveyor belts stand at the forefront of revolutionizing warehouse operations. Their unique safety features, coupled with efficiency-enhancing capabilities, make them indispensable components of modern material handling systems. By prioritizing safety and efficiency simultaneously, PVK logistics conveyor belts play a pivotal role in creating safer work environments and driving operational excellence within warehouses.