In today’s industrial landscape, conveyor belts play a vital role in various sectors, from manufacturing to logistics. However, selecting the right PVK (Polyvinyl Chloride and Polyurethane) conveyor belt supplier can be a complex and critical decision. The choice you make can significantly impact your operational efficiency, reliability, and overall success. This comprehensive guide aims to provide you with a detailed roadmap for choosing the most suitable PVK conveyor belt supplier tailored to your industry or application.

Introduction

Conveyor belts are the unsung heroes of numerous industries, silently moving products, materials, and goods from one point to another. Whether it’s the automotive, food processing, packaging, or any other industry, the choice of the right PVK conveyor belt supplier is paramount. This guide aims to demystify the process, enabling you to make an informed decision that aligns with your specific industry or application needs.

Understanding Your Industry and Application Needs

- Assessing the Unique Requirements of Your Industry

The journey to selecting the perfect PVK conveyor belt supplier starts with a profound understanding of your industry’s unique demands and challenges.

Overview of Industries Using PVK Conveyor Belts

Begin by identifying industries that share similarities with your own. This will help you compile a list of potential PVK conveyor belt suppliers who specialize in your sector.

Identifying Specific Challenges and Demands

Within your industry, specific challenges and demands may dictate the choice of conveyor belts. For instance, the food processing sector may prioritize hygiene and FDA compliance, while the automotive industry may require belts with outstanding durability and resistance to oils and grease.

- Defining the Application Requirements

Once you’ve gained insight into your industry’s overarching needs, it’s time to zoom in on your application’s specific requirements. PVK conveyor belts serve a multitude of purposes, from conveying heavy loads to fragile products.

Highlighting Different Applications for PVK Conveyor Belts

PVK conveyor belts find use in diverse applications, including assembly lines, packaging, baggage handling, and more. Identifying which application best describes your needs is pivotal to PVK conveyor belt supplier selection.

Determining the Critical Performance Criteria

Critical performance criteria, such as load capacity, speed, wear resistance, and environmental conditions, must be pinpointed to make an educated choice. Creating a checklist of these criteria will help evaluate potential suppliers later in the process.

Researching Potential PVK Conveyor Belt Suppliers

With a clear understanding of your industry and application needs, it’s time to compile a list of potential PVK conveyor belt suppliers. This phase involves thorough research and due diligence to identify reputable companies that can meet your requirements.

- Identifying a List of Potential PVK conveyor belt suppliers

Industry-Specific Directories or Associations

Many industries have directories or associations that maintain lists of approved or trusted suppliers. Check whether your industry provides such resources.

Online Research and Reviews

Leverage online resources, including search engines, industry forums, and social media platforms, to identify potential PVK conveyor belt suppliers. Keep an eye out for customer reviews and ratings to gain insights into PVK conveyor belt supplier reputation and performance.

- Evaluating Supplier Credentials

Once you have a list of potential PVK conveyor belt suppliers, it’s time to scrutinize their credentials and qualifications. Consider the following key factors:

Company History and Reputation

Dive into the history of each supplier. How long have they been in business, and what is their reputation in the industry? Companies with a long-standing track record often exhibit a commitment to quality.

Certifications and Quality Standards

Check if the PVK conveyor belt supplier holds relevant certifications and adheres to industry-specific quality standards. Certifications such as ISO are indicators of a company’s dedication to quality management.

Experience with Similar Industries or Applications

Explore whether the supplier has experience serving industries or applications similar to yours. Experience in your niche can be a significant advantage, as the PVK conveyor belt supplier is more likely to understand your unique needs.

Assessing Product Quality and Performance

The quality and performance of PVK conveyor belts are critical factors that directly influence your operational efficiency and reliability. To make an informed decision, you need to delve into the specifics of the products offered by potential PVK conveyor belt suppliers.

- Understanding PVK Conveyor Belt Specifications

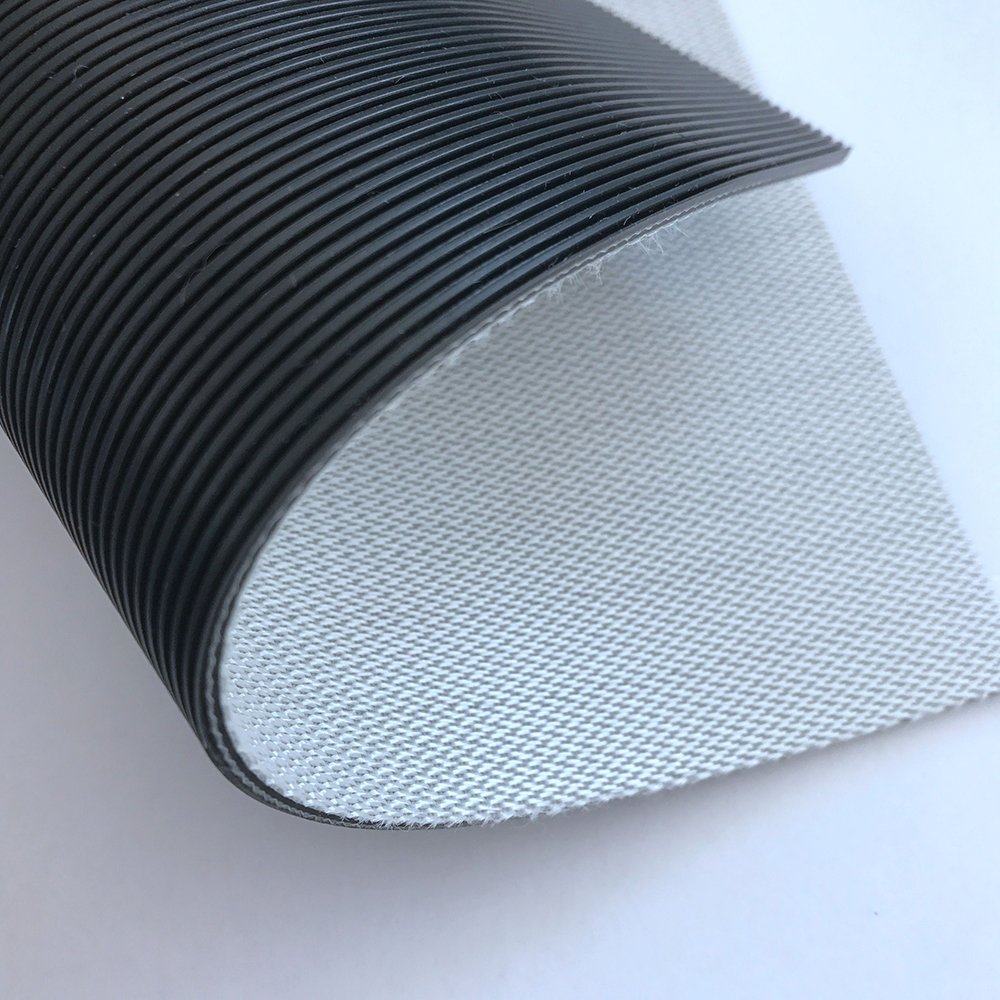

Material Composition

PVK conveyor belts may feature varying material compositions. Familiarizing yourself with the materials used is crucial since it impacts flexibility, durability, and resistance to chemicals.

Dimensions and Tolerances

Ensure that the belts’ dimensions and tolerances align with your application’s requirements. Any deviations can lead to operational issues and potential damage.

- Requesting Product Samples or Data Sheets

To gain firsthand insight into product quality, consider requesting samples from potential PVK conveyor belt suppliers. Alternatively, ask for detailed data sheets that provide specifications, performance data, and certifications.

- Analyzing Product Testing and Quality Control Measures

Inquire about the PVK conveyor belt supplier’s product testing and quality control processes. Reputable suppliers subject their products to rigorous testing to ensure they meet specified standards and perform reliably.

Evaluating Customization and Lead Time

The ability to customize PVK conveyor belts to suit your specific needs and understanding the lead time for orders are crucial factors in PVK conveyor belt supplier selection.

- Inquiring About Customization Options

Tailored Belt Designs

Engage in discussions regarding customization options with each supplier. Can they tailor belt designs to meet your unique requirements, such as size, shape, or special features?

Special Coatings or Features

In certain cases, you may require belts with specialized coatings or features, such as high-temperature resistance or anti-static properties. Ensure that the PVK conveyor belt supplier can accommodate such requests.

- Determining Lead Times for Orders

Knowing the lead time for receiving your PVK conveyor belt orders is vital for your operational planning. Different PVK conveyor belt suppliers may offer varying lead times, so it’s crucial to clarify this information.

Standard Lead Times

Request information on standard lead times for orders. This will give you an idea of how quickly you can expect to receive your belts under normal circumstances.

Expedited Options (If Available)

Inquire about expedited or rush-order options, especially if you have urgent requirements. Some PVK conveyor belt suppliers may offer faster delivery for an additional fee.

Pricing and Cost Considerations

While quality and customization are paramount, pricing and cost considerations are equally crucial. Balancing quality with affordability is an essential aspect of supplier selection.

Obtaining Price Quotes from Multiple Suppliers

Request price quotes from each potential PVK conveyor belt supplier on your list. Provide them with comprehensive details about your requirements to ensure accurate quotes.

Assessing the Total Cost of Ownership

Consider the total cost of ownership, which encompasses not just the initial purchase price but also ongoing expenses. Factors to incorporate in your assessment are:

Maintenance and Replacement Costs

Evaluate long-term maintenance and replacement costs associated with PVK conveyor belts. Durable belts may require fewer replacements and repairs, resulting in cost savings over time.

Long-Term Durability and Reliability

Assess the anticipated lifespan and reliability of the PVK conveyor belts. High-quality belts tend to have a longer operational life, reducing the frequency of replacements.

Checking References and Past Projects

To bolster your confidence in your choice of PVK conveyor belt supplier, it’s crucial to examine their references and past projects.

- Requesting References from the Supplier

Ask each PVK conveyor belt supplier for references from previous customers who share similarities with your industry or application needs. Take the initiative to contact these references to gain insights into their experiences with the supplier.

- Reviewing Case Studies or Success Stories

In addition to references, inquire whether the PVK conveyor belt supplier has case studies or success stories related to PVK conveyor belt installations. These can offer valuable insights into their ability to overcome specific challenges.

- Analyzing Feedback and Testimonials

Review testimonials and feedback from other customers. Online reviews and testimonials can provide significant information regarding a PVK conveyor belt supplier’s performance and customer satisfaction levels.

Customer Support and Service

A supplier’s commitment to customer support and service can significantly impact your experience with their PVK conveyor belts.

- Evaluating the PVK conveyor belt supplier’s Customer Service Responsiveness

Consider how responsive and accessible the supplier’s customer service team is. Will they be readily available to address any issues or questions that may arise?

- Warranty and After-Sales Support

Inquire about the warranty offered on PVK conveyor belts. A robust warranty is indicative of the PVK conveyor belt supplier’s confidence in the quality of their products. Additionally, ask about the availability of after-sales support and technical assistance.

- Availability of Technical Assistance and Troubleshooting

Check whether the PVK conveyor belt supplier provides technical assistance and troubleshooting support. This can be invaluable in resolving any operational issues promptly and efficiently.

Making the Final Decision

After conducting comprehensive research and evaluation, it’s time to make the final decision and select the most suitable PVK conveyor belt supplier for your industry or application.

- Weighing the Pros and Cons of Each Supplier

Create a list of the pros and cons of each potential PVK conveyor belt supplier based on the factors discussed in this guide. Consider which supplier aligns most closely with your industry and application needs.

- Considering the Alignment with Industry and Application Requirements

Review your industry and application requirements and compare them to what each supplier offers. Choose the supplier that best aligns with your specific needs.

Conclusion

In conclusion, the choice of the right PVK conveyor belt supplier for your industry or application is a pivotal decision that demands careful consideration. By understanding your industry and application needs, researching potential suppliers, assessing product quality and customization options, considering pricing and cost factors, checking references, and evaluating customer support, you can confidently select a supplier that not only fulfills your immediate needs but also contributes to the long-term success of your business or industry.

Remember that the selection of a PVK conveyor belt supplier is a long-term commitment, and investing time and effort in the selection process is indispensable. By following the steps outlined in this guide, you can make an informed decision that positively impacts your operations and sets the stage for efficiency, reliability, and success in your industry or application.