Introduction

In industries reliant on conveyor systems for heavy-duty applications, the durability and resilience of PVC conveyor belts are paramount. High-quality PVC conveyor belt manufacturers employ a range of strategies to ensure these belts withstand the rigors of demanding industrial environments. This article delves into the methods utilized by these manufacturers to guarantee durability and resistance to wear and tear in heavy-duty applications.

Selection of High-Quality Raw Materials

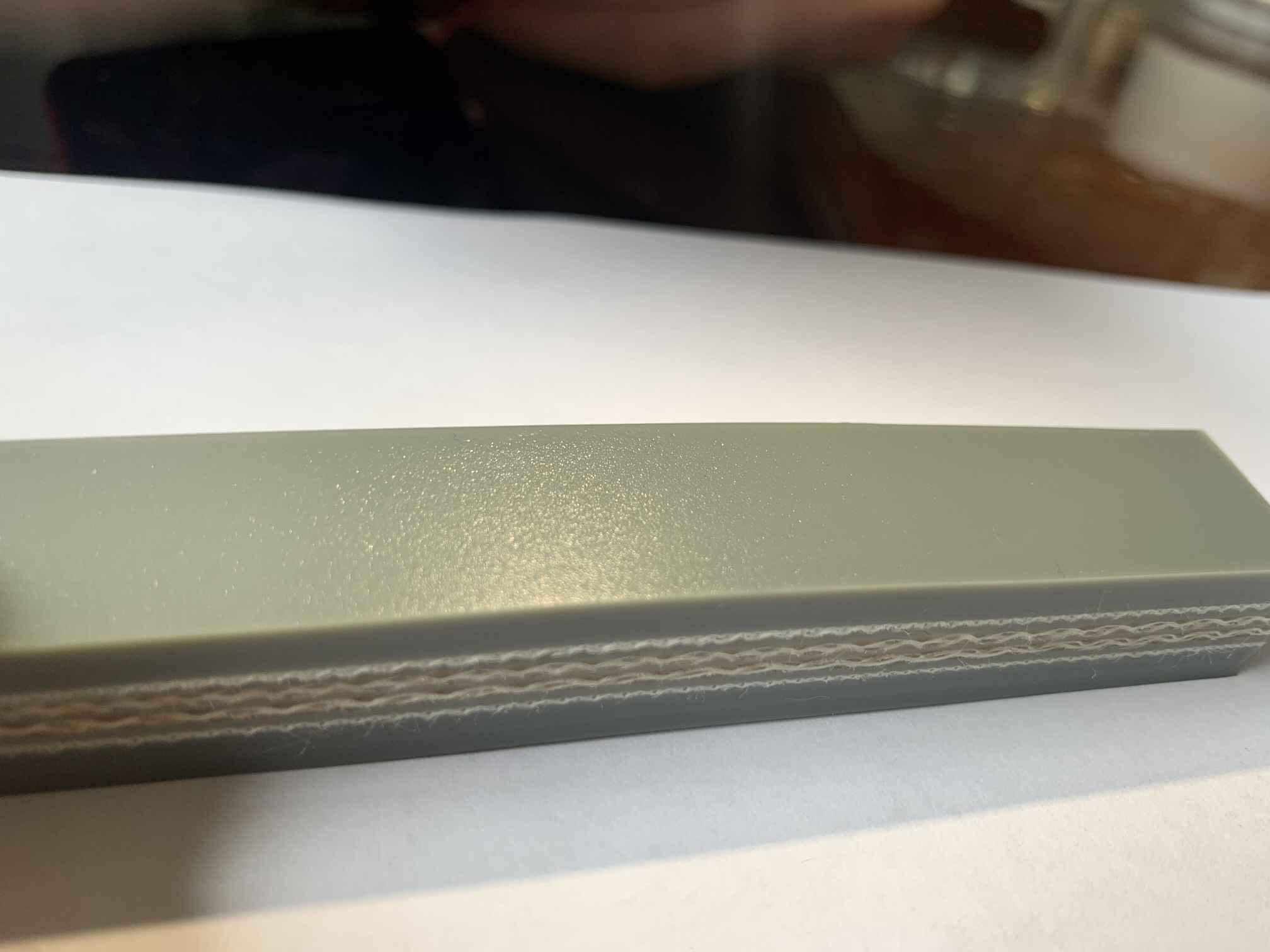

To fortify PVC conveyor belts for heavy-duty use, manufacturers prioritize superior raw materials. High-quality PVC compounds, additives, and robust fabric layers or reinforcements form the backbone of durable belts. These materials are chosen for their exceptional resilience against abrasion, impact, and stretching, crucial factors in challenging industrial settings.

Advanced Manufacturing Techniques

Manufacturers employ advanced manufacturing techniques to ensure the durability of PVC conveyor belts. Precision in the belt-making process is paramount for uniformity and strength. Innovative bonding methods for layers and fabric reinforcements are utilized to create a resilient and durable structure. Ensuring consistent belt thickness and surface quality is another critical aspect considered during manufacturing.

Design and Engineering for Heavy-Duty Use

Customized designs are crafted to withstand specific heavy-duty applications. These designs incorporate features to resist impacts and possess high tensile strength. Manufacturers optimize structural integrity and load-bearing capacities, ensuring the belts can withstand the pressures of demanding industrial operations.

Testing and Quality Assurance Protocols

Rigorous testing procedures are a hallmark of high-quality PVC conveyor belt manufacturing. These procedures assess material strength and performance, ensuring belts meet stringent industry standards and certifications. Quality control measures are integrated throughout the manufacturing process to maintain consistency and reliability.

Surface Protection and Coating Technologies

Manufacturers apply protective coatings to enhance resistance to abrasion and chemicals. Innovative surface treatments are utilized to reduce friction and wear, contributing to enhanced belt longevity. Additionally, consideration is given to properties such as anti-static or flame-retardant features for specific applications, bolstering durability in diverse industrial settings.

Continuous Research and Development Efforts

High-quality PVC conveyor belt manufacturers prioritize continuous research and development efforts. These endeavors focus on improving belt performance by incorporating technological advancements into manufacturing processes. By responding to evolving industry needs and challenges, manufacturers ensure their belts remain at the forefront of durability and performance.

Case Studies and Industry Applications

Real-world applications demonstrate the efficacy of high-quality PVC conveyor belts in heavy-duty environments. Case studies highlight successful applications in various industries, showcasing the belts’ durability, wear-resistance, and longevity. Performance data from these applications reinforces the reliability of these belts in challenging industrial settings.

Conclusion

In conclusion, the durability and resistance to wear and tear in high-quality PVC conveyor belts are achieved through a combination of meticulous material selection, advanced manufacturing techniques, design engineering, rigorous testing, surface protection, and ongoing research efforts. These strategies collectively ensure that these belts maintain exceptional performance in industries with demanding applications, providing reliability and longevity.