Introduction

Conveyor belts serve as critical components in various industries, facilitating the movement of goods, materials, and products along production lines. Within this domain, polyurethane conveyor felt belts have emerged as versatile and durable solutions, finding applications across numerous sectors due to their unique properties and benefits.

Understanding Polyurethane Conveyor Felt Belts

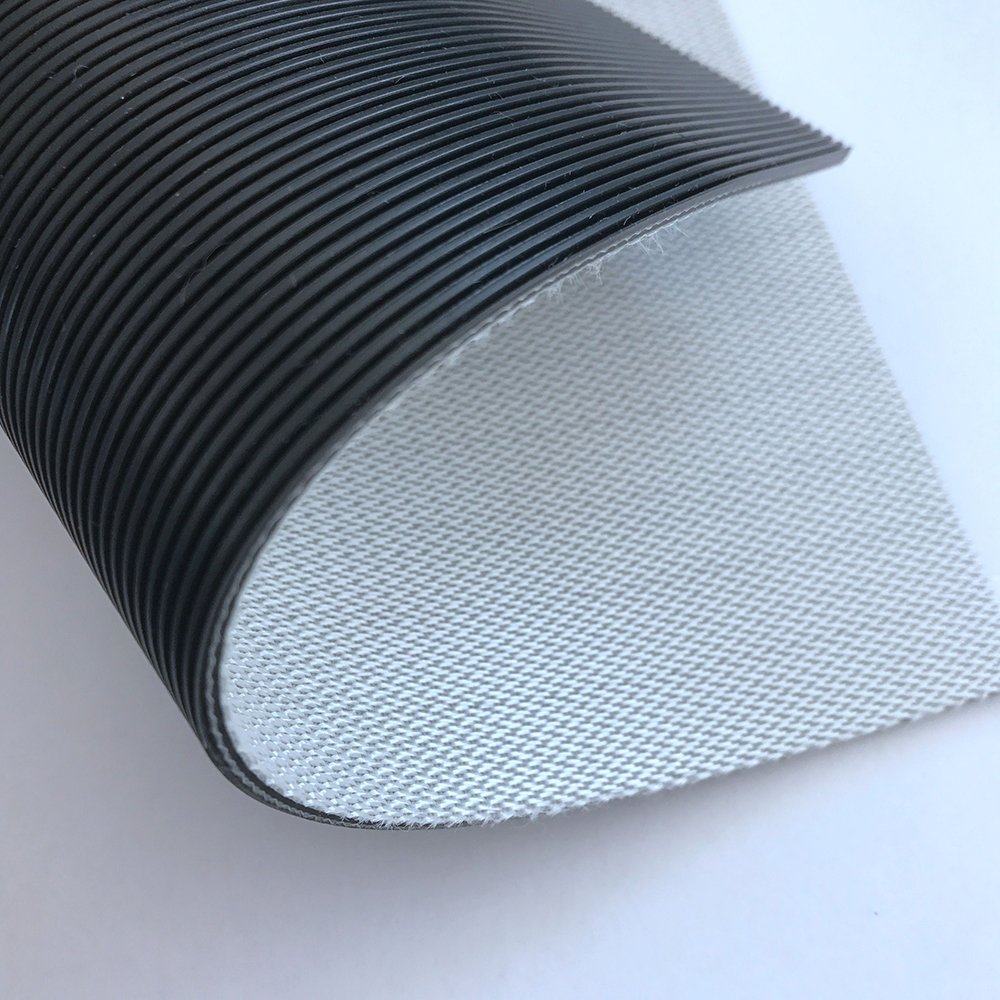

Polyurethane conveyor felt belts are crafted from a combination of polyurethane and felt materials. This composition grants these belts exceptional properties such as durability, flexibility, resistance to abrasion, and the ability to withstand extreme temperatures and harsh conditions, making them ideal for conveying diverse materials in industrial settings.

Role and Applications of Polyurethane Conveyor Felt Belts

Industries such as manufacturing, food processing, packaging, and logistics extensively utilize polyurethane conveyor felt belts. Their applications range from conveying delicate materials in electronics manufacturing to heavy-duty applications in automotive and mining sectors. Their versatility allows for use in sorting, packaging, and various conveying processes, enabling seamless operations across multiple industries.

Factors Considered by Manufacturers

Manufacturers of polyurethane conveyor felt belts focus on utilizing high-quality materials, employing advanced manufacturing techniques, and offering customization options to meet specific industry requirements. The emphasis is on creating belts that exhibit resilience, longevity, and adaptability to diverse operational environments.

Key Features and Advantages

Polyurethane conveyor felt belts boast several advantages over traditional belt materials. Their exceptional durability, wear resistance, flexibility, and low maintenance requirements contribute to extended service life and reduced downtime. Additionally, their ability to operate under extreme temperatures and harsh conditions ensures reliability in demanding industrial settings.

Leading Manufacturers of Polyurethane Conveyor Felt Belts

Prominent manufacturers in this sector emphasize specialization and innovation. Profiles of these manufacturers highlight their product range, technological advancements, market presence, and customer-centric solutions. Case studies or testimonials illustrate successful implementations, underscoring the belts’ effectiveness in diverse industrial applications.

Quality Standards and Certifications

Manufacturers adhere to stringent quality standards and certifications to ensure the production of high-performance conveyor belts. Compliance with industry-specific standards underscores the commitment to delivering reliable and superior-quality products to customers.

Customization Options and Client-specific Solutions

Manufacturers offer customization options to tailor belts to meet specific client requirements. This includes variations in belt thickness, surface textures, coatings, and specialized designs optimized for distinct industrial applications.

Environmental Impact and Sustainability Measures

In response to environmental concerns, manufacturers are increasingly adopting eco-friendly materials and sustainable practices in belt manufacturing. Efforts are made to minimize environmental impact through efficient production processes and the use of recyclable materials.

Conclusion

Polyurethane conveyor felt belt manufacturers play a pivotal role in providing essential solutions for industries reliant on conveyor systems. The continuous innovation, focus on quality, customization capabilities, and commitment to sustainability ensure the reliability and versatility of these belts across diverse industrial applications.