Introduction

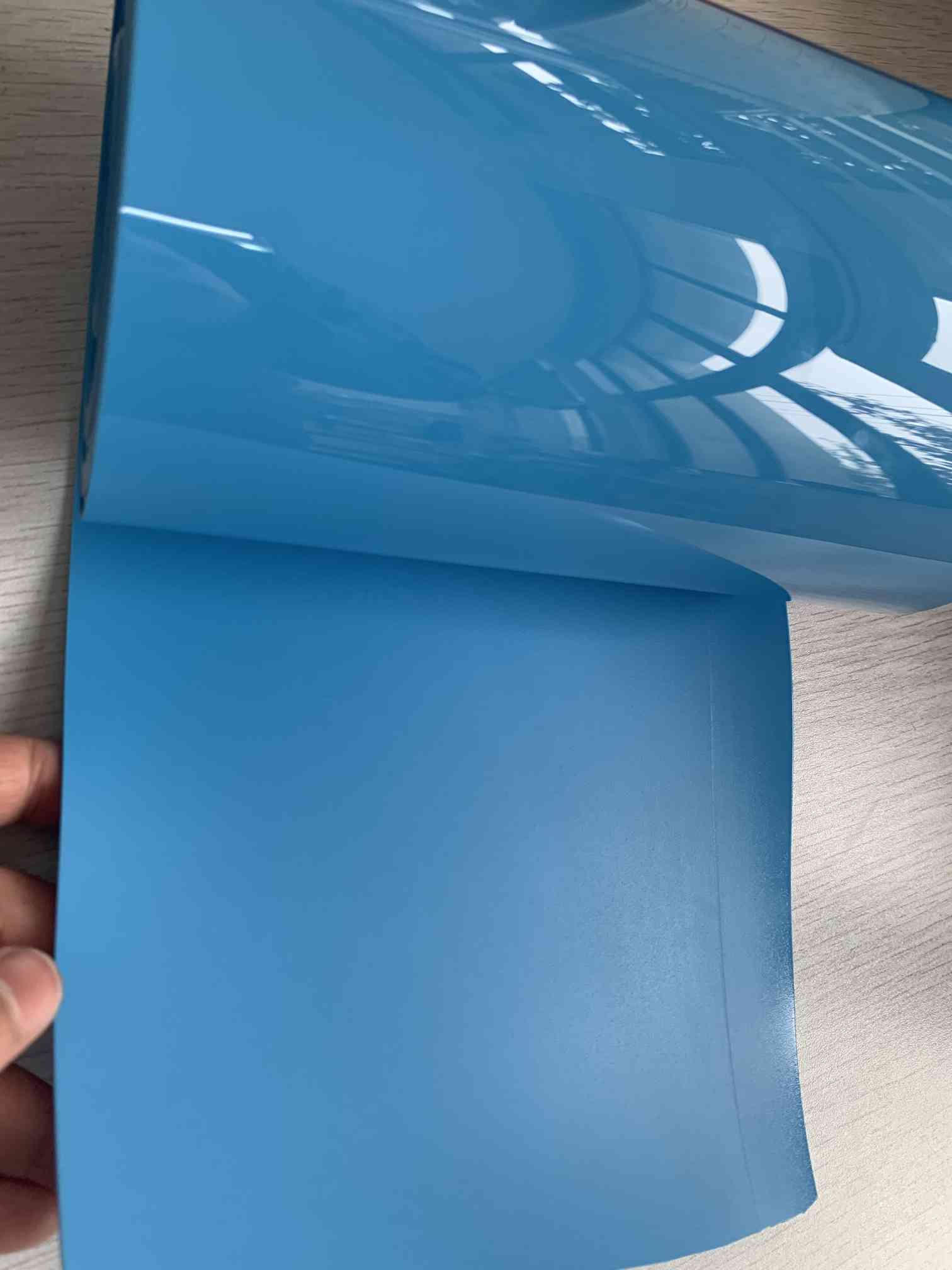

Conveyor belts are the unsung heroes of modern industrial and logistics operations, silently facilitating the movement of goods and materials. While they come in various types, solid woven conveyor belts have gained recognition for their remarkable impact on improving operations and productivity. In this article, we’ll delve into the success stories of businesses that transitioned to solid woven conveyor belts supplied by a trusted company. We’ll explore the unique challenges they faced and how these belts revolutionized their operations and productivity.

Business 1: Maximizing Efficiency with Solid Woven Conveyor Belts

Our first success story revolves around Company A, a manufacturing facility that grappled with the challenges of conveyor belt reliability and durability. Prior to switching to solid woven conveyor belts, they were frequently plagued by costly downtimes and repairs. The company had high maintenance costs and a constant need for belt replacements, which hampered their operational efficiency.

After adopting solid woven conveyor belts, the transformation was remarkable. The robust construction and resilience of these belts significantly reduced downtime due to wear and tear. The company’s maintenance expenses dropped substantially as the need for repairs became rare. This not only saved them money but also allowed their production lines to operate at full capacity for extended periods.

Company A also reported improvements in the quality of their products. The solid woven belts ensured a consistent and gentle transport of delicate materials, resulting in fewer defects and product damage. As a result, the company’s reputation for quality products soared, and customer satisfaction followed suit. The switch to solid woven conveyor belts not only boosted efficiency but also contributed to an increase in profitability.

Business 2: Enhancing Safety and Efficiency in a Warehouse

Company B, a large warehouse and distribution center, had its fair share of challenges before making the transition to solid woven conveyor belts. Safety concerns and operational bottlenecks were the primary issues they sought to address. They needed a solution that would simultaneously improve worker safety and streamline their distribution process.

Solid woven conveyor belts were the answer to their prayers. The belts’ design and construction met rigorous safety standards, ensuring employee well-being. They were no longer concerned about accidents caused by belt slippage or material spillage. Employee morale improved significantly as the workplace became safer and more efficient.

In addition to the safety benefits, Company B also experienced a boost in productivity. Solid woven belts with a smooth, consistent surface reduced the friction and drag previously experienced with their old belts. This led to faster material handling and a more efficient workflow. As a result, they could handle larger volumes of goods in less time, ultimately improving their bottom line.

Business 3: Resolving Material Handling Challenges

Company C, a recycling plant, was grappling with a unique set of challenges related to material handling. They needed a solution that could withstand the abrasive and aggressive nature of their operation. Traditional conveyor belts they used in the past couldn’t endure the heavy loads and harsh conditions they faced daily.

Switching to solid woven conveyor belts was a game-changer for Company C. These belts, specifically designed to handle tough and abrasive materials, outperformed their predecessors by a long shot. The solid woven construction provided the necessary strength and durability to withstand the demanding environment of the recycling plant.

The result? Reduced maintenance and replacement costs, which were previously a significant drain on their budget. Company C was able to allocate those funds to other critical areas of their operation, such as upgrading equipment and increasing recycling capacity. The reliability of solid woven belts translated to fewer disruptions and increased operational uptime.

Common Themes and Benefits

These success stories reveal common themes and benefits that are integral to the adoption of solid woven conveyor belts:

- Improved Reliability: In each case, the reliability of solid woven belts significantly reduced downtime and maintenance costs. Businesses experienced a substantial decrease in operational disruptions.

- Enhanced Product Quality: Solid woven conveyor belts ensured the gentle and consistent transport of materials, resulting in fewer defects and product damage. This led to an increase in product quality and customer satisfaction.

- Worker Safety: The belts’ safety features reduced the risk of accidents and injuries, boosting employee morale and creating a safer work environment.

- Increased Efficiency: Solid woven belts’ smooth surfaces reduced friction and drag, resulting in faster material handling and more streamlined processes. This led to increased productivity and cost savings.

Conclusion

The success stories of these businesses showcase the profound impact of solid woven conveyor belts on operations and productivity. Whether it’s reducing downtime and maintenance costs, enhancing product quality, ensuring worker safety, or improving efficiency, these belts offer a comprehensive solution to various challenges faced by industries across the board.

Selecting a trusted supplier of solid woven conveyor belts is the first step toward reaping these benefits. Companies like [Supplier’s Name] provide the expertise and high-quality products needed to transform your operations and improve your productivity. As you consider the unique challenges of your industry, remember the lessons learned from these success stories and how solid woven conveyor belts can elevate your business to new heights. The investment in these belts not only drives efficiency but also paves the way for a safer, more profitable, and environmentally responsible future.