Introduction

In the manufacturing industry, the quality of materials and components used in production processes is of utmost importance. When it comes to PE (Polyethylene) belts, which find applications in various industries, ensuring that the supplier adheres to specific quality certifications and standards is crucial. These certifications and standards not only guarantee the quality of the product but also ensure its safety and reliability. In this article, we will explore the significance of quality certifications and standards for PE belt suppliers and the specific requirements that they should meet to be considered reliable.

Understanding PE Belts and Their Applications

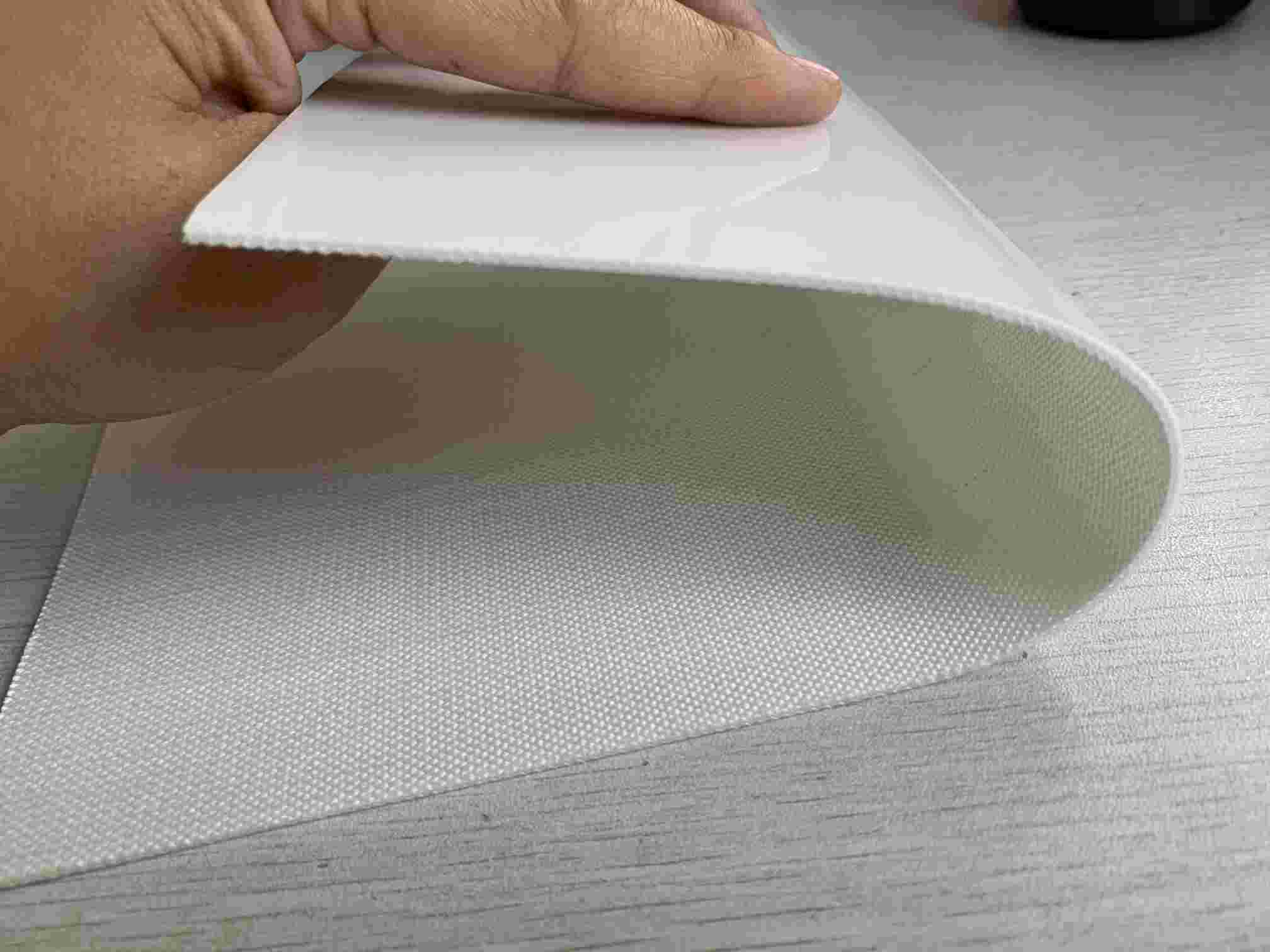

Before delving into quality certifications and standards, it’s essential to understand the role of PE belts in various industries. PE belts are known for their versatility and wide range of applications, making them a valuable component in manufacturing and industrial processes. Some common uses of PE belts include conveying, sealing, and packaging in industries like food processing, automotive manufacturing, and agriculture.

PE belts are valued for their low friction, abrasion resistance, chemical resistance, and low maintenance requirements. These characteristics make them a popular choice in industries that rely on efficient and reliable material handling. To maintain the quality and safety of products manufactured with PE belts, it is essential to ensure that the belts themselves meet stringent quality standards.

Quality Certifications and Standards for PE Belt Suppliers

ISO 9001 Certification

ISO 9001 is a globally recognized quality management system standard that sets the framework for consistent product quality, customer satisfaction, and continuous improvement. Suppliers who hold ISO 9001 certification have undergone a rigorous evaluation of their quality management systems. Adhering to ISO 9001 standards demonstrates a commitment to maintaining high product quality and ensuring customers’ needs are met consistently.

PE belt suppliers seeking ISO 9001 certification are required to establish and maintain processes that monitor and improve product quality, provide effective customer communication, and ensure a strong focus on customer satisfaction. By adhering to ISO 9001, suppliers demonstrate their dedication to delivering reliable and high-quality PE belts to their customers.

Industry-Specific Standards

Various industries have their own unique quality standards and certifications. These industry-specific standards are designed to address the particular needs and requirements of sectors where PE belts are commonly used. For example:

In the food processing industry, food safety standards like HACCP (Hazard Analysis and Critical Control Points) may apply. PE belt suppliers should ensure their products meet these standards to guarantee that they are safe for food handling and processing.

In automotive manufacturing, suppliers may need to meet specific quality requirements and standards set by automotive organizations to ensure the reliability of PE belts used in production processes.

In agriculture, the use of PE belts for conveying and handling crops may require compliance with agricultural equipment safety standards to protect workers and maintain product quality.

Industry-specific standards are vital for ensuring that PE belts are safe, reliable, and meet the unique demands of various applications. Suppliers must familiarize themselves with these standards and ensure that their products conform to them.

Compliance with Regulatory Requirements

In addition to quality certifications and industry-specific standards, PE belt suppliers must also comply with regulatory requirements. Regulatory bodies may impose specific guidelines and standards to ensure product safety and performance. These regulations can encompass areas such as material safety, environmental considerations, and product specifications.

Suppliers must be proactive in staying informed about relevant regulations and ensuring that their PE belts meet all necessary requirements. Compliance with regulatory requirements not only safeguards product quality but also protects against potential legal issues and liabilities.

Customer Audits and Quality Assurance

To further ensure that PE belt suppliers adhere to quality certifications and standards, customers often conduct audits of supplier facilities and processes. These audits serve as a way for customers to assess the supplier’s commitment to quality and compliance with established standards.

In response to customer audits, PE belt suppliers implement robust quality assurance practices. Quality assurance involves a systematic approach to maintaining and improving product quality. This includes processes for testing and inspecting products, addressing non-conformities, and making continuous improvements. By actively engaging in quality assurance, suppliers can demonstrate their commitment to delivering reliable and compliant PE belts.

Case Studies and Examples

To illustrate the real-world benefits of adhering to quality certifications and standards, let’s examine a few case studies and examples of PE belt suppliers that have successfully met these requirements.

- Case Study 1: Food Processing Industry

A PE belt supplier that specializes in belts for food processing facilities sought ISO 9001 certification and complied with HACCP standards. As a result, they not only improved their internal quality management processes but also gained the trust of numerous food processing companies. Their belts are now widely used in the industry, ensuring the safety and quality of food products.

- Case Study 2: Automotive Manufacturing

An automotive manufacturing plant required PE belts for its production lines. They partnered with a PE belt supplier that adhered to ISO 9001 and met automotive industry standards. This supplier’s belts not only increased the efficiency of the manufacturing process but also ensured product quality and safety. Consequently, the supplier became a trusted partner in the automotive sector.

- Case Study 3: Agricultural Equipment

Agricultural equipment manufacturers required PE belts for conveying crops and materials. A PE belt supplier that complied with agricultural safety standards and regulatory requirements provided belts that were not only robust but also safe for use in agricultural environments. These belts contributed to the safety of agricultural workers and the quality of the equipment.

Conclusion

In conclusion, quality certifications and standards play a pivotal role in ensuring that PE belt suppliers deliver reliable, safe, and high-quality products. These certifications and standards, including ISO 9001, industry-specific guidelines, and regulatory requirements, establish a framework for consistent quality and safety in various applications.

PE belt suppliers that proactively seek and adhere to these certifications and standards demonstrate their commitment to delivering products that meet or exceed customer expectations. This commitment not only enhances product quality but also builds trust and credibility in the industry.

As a customer or buyer, it is essential to prioritize suppliers that adhere to these quality certifications and standards. By doing so, you can be confident that the PE belts you source will not only meet your needs but also maintain the quality, safety, and reliability that are crucial in manufacturing and industrial processes. Ultimately, the adherence to these standards ensures that PE belt suppliers are not just reliable but also critical partners in your pursuit of high-quality and efficient production.