Introduction

In the intricate web of industrial processes, conveyor belts play a vital role in the seamless movement of materials. The performance and durability of these conveyor belts are paramount, and achieving these attributes requires adherence to industry standards and certifications. In this article, we explore the specific standards and certifications that a PU conveyor belt supplier should meet to guarantee the performance and durability of their products.

Understanding Industry Standards for PU Conveyor Belts

Conveyor belts are subject to rigorous standards set by various organizations to ensure their reliability and safety. ANSI/CEMA standards, established by the Conveyor Equipment Manufacturers Association, provide comprehensive guidelines for conveyor design, construction, and performance. Additionally, the International Organization for Standardization (ISO) has standards specifically dedicated to conveyor belts, covering aspects such as dimensions, testing methods, and safety requirements. Understanding and applying these industry standards is fundamental to producing conveyor belts that meet the demands of diverse applications.

Certifications Ensuring Quality and Compliance

Certifications serve as a badge of honor, signifying that a product meets or exceeds specified requirements. For PU conveyor belts, certifications are essential in validating the quality and compliance of the product. Certifying bodies such as TÜV SÜD, Bureau Veritas, and others play a crucial role in independently verifying that a conveyor belt meets industry standards. Recognized certifications assure customers that the product has undergone rigorous testing and complies with established benchmarks for performance and durability.

Performance Testing and Criteria

The performance of PU conveyor belts is gauged through various criteria, including durability, wear resistance, and tensile strength. Performance testing methods involve subjecting the belts to simulated operational conditions to assess their ability to withstand wear and tear over time. Compliance with industry standards ensures that the conveyor belts not only meet basic performance requirements but also deliver optimal functionality in diverse industrial environments.

PU conveyor belt supplier Compliance with Industry Standards

Choosing a PU conveyor belt supplier that prioritizes compliance with industry standards is critical. Transparent communication from suppliers regarding their adherence to standards is a key factor in making informed decisions. Reputable PU conveyor belt suppliers provide documentation and certifications, offering customers the assurance that the conveyor belts they provide meet the necessary benchmarks for quality, performance, and durability.

Regulatory Compliance and Safety Standards

In addition to industry standards, regulatory compliance and safety standards are integral to the overall reliability of conveyor belts. Regulatory bodies, such as the Occupational Safety and Health Administration (OSHA) in the United States, set guidelines to ensure worker safety around conveyor systems. Compliance with safety standards not only safeguards workers but also contributes to the longevity of conveyor systems by preventing accidents and minimizing wear and tear caused by improper use.

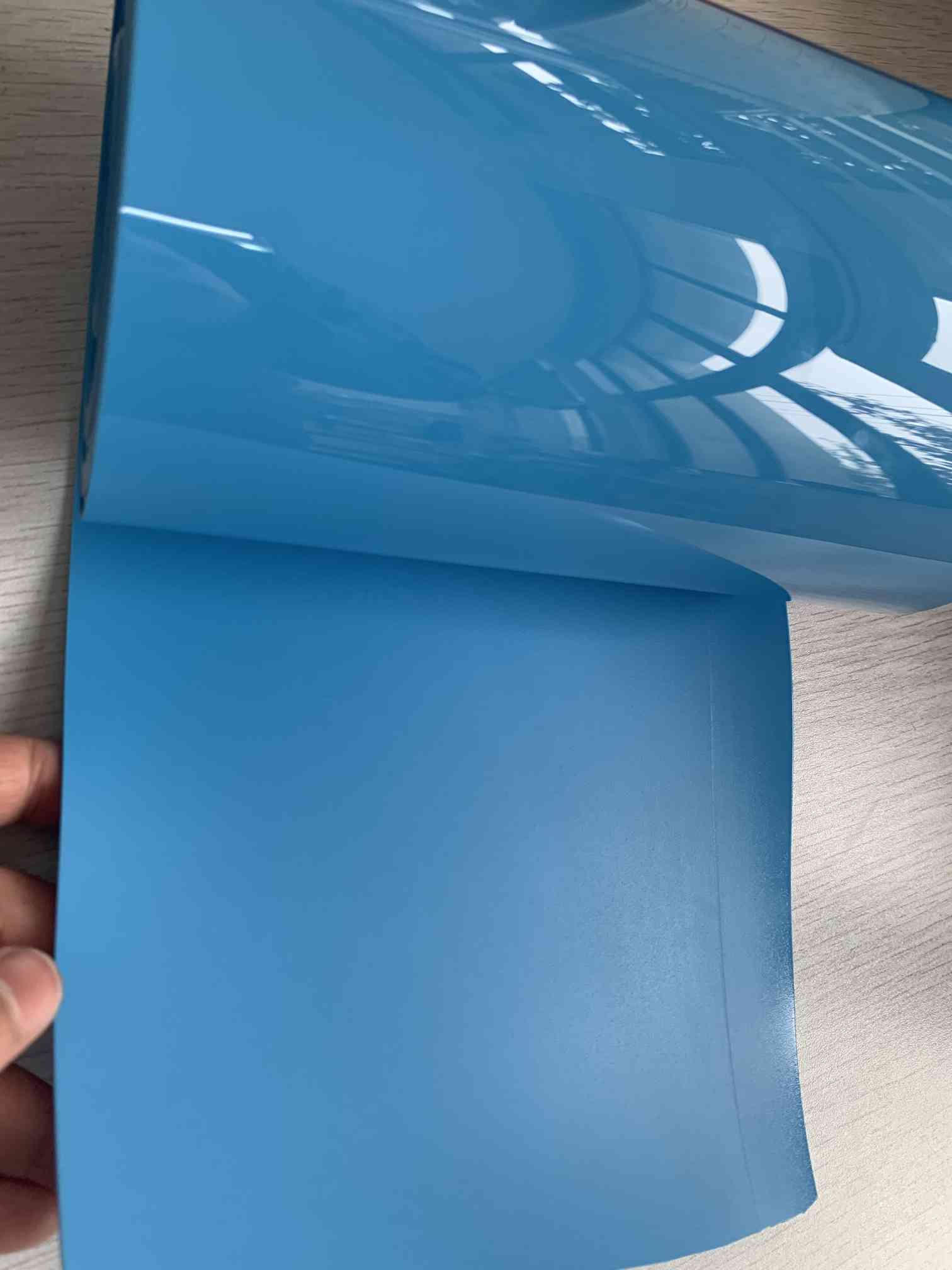

Importance of Material Quality

The quality of materials used in manufacturing PU conveyor belts is a cornerstone of their performance and durability. Adherence to material quality standards ensures that the conveyor belts are constructed using materials that can withstand the specific challenges posed by industrial environments. Certifications related to material quality provide an additional layer of assurance regarding the integrity of the conveyor belt components.

Environmental and Sustainability Certifications

In an era where environmental sustainability is a global priority, certifications related to eco-friendly manufacturing and recyclability have gained prominence. Sustainable practices in the manufacturing of conveyor belts not only contribute to environmental stewardship but also reflect a commitment to long-term quality. Certifications in this realm validate a PU conveyor belt supplier’s dedication to minimizing their environmental footprint, offering customers an opportunity to support environmentally conscious practices.

Case Studies of Successful Implementation

Real-world examples underscore the tangible benefits of adhering to industry standards and certifications. Industries that prioritize certified PU conveyor belts report enhanced performance, prolonged lifespan, and reduced maintenance costs. Case studies provide a practical understanding of how the careful selection of certified conveyor belts contributes to the overall efficiency of industrial operations.

Challenges and Considerations

While the importance of industry standards and certifications is evident, navigating the certification landscape can pose challenges. PU conveyor belt suppliers and manufacturers may face obstacles in maintaining compliance, from evolving standards to changes in manufacturing processes. Strategies for overcoming these challenges include staying informed about updates to standards, investing in continuous training, and fostering a culture of quality and compliance within the organization.

Conclusion

In conclusion, the adherence to industry standards and certifications is non-negotiable when it comes to ensuring the performance and durability of PU conveyor belts. From ANSI/CEMA standards to ISO certifications, each benchmark serves as a pillar supporting the reliability of conveyor systems. Certifications, whether related to material quality, safety, or sustainability, provide customers with the confidence that they are investing in conveyor belts that meet the highest standards in the industry. As businesses strive for efficiency and sustainability, choosing PU conveyor belt suppliers that prioritize compliance with industry standards becomes a strategic decision, laying the foundation for resilient and reliable conveyor systems that power industrial processes across the globe.