Introduction

In the world of industrial material handling, the choice of a conveyor belt can significantly impact operations. Among the various types of conveyor belts available, white PVC conveyor belts have gained popularity for their versatility and durability. However, when selecting awhite PVC conveyor belt supplier for these essential components of your material handling system, it’s crucial to ensure product quality and reliability. One way to achieve this is by considering industry standards and certifications. In this article, we’ll explore the significance of industry standards and certifications when choosing a white PVC conveyor belt supplier.

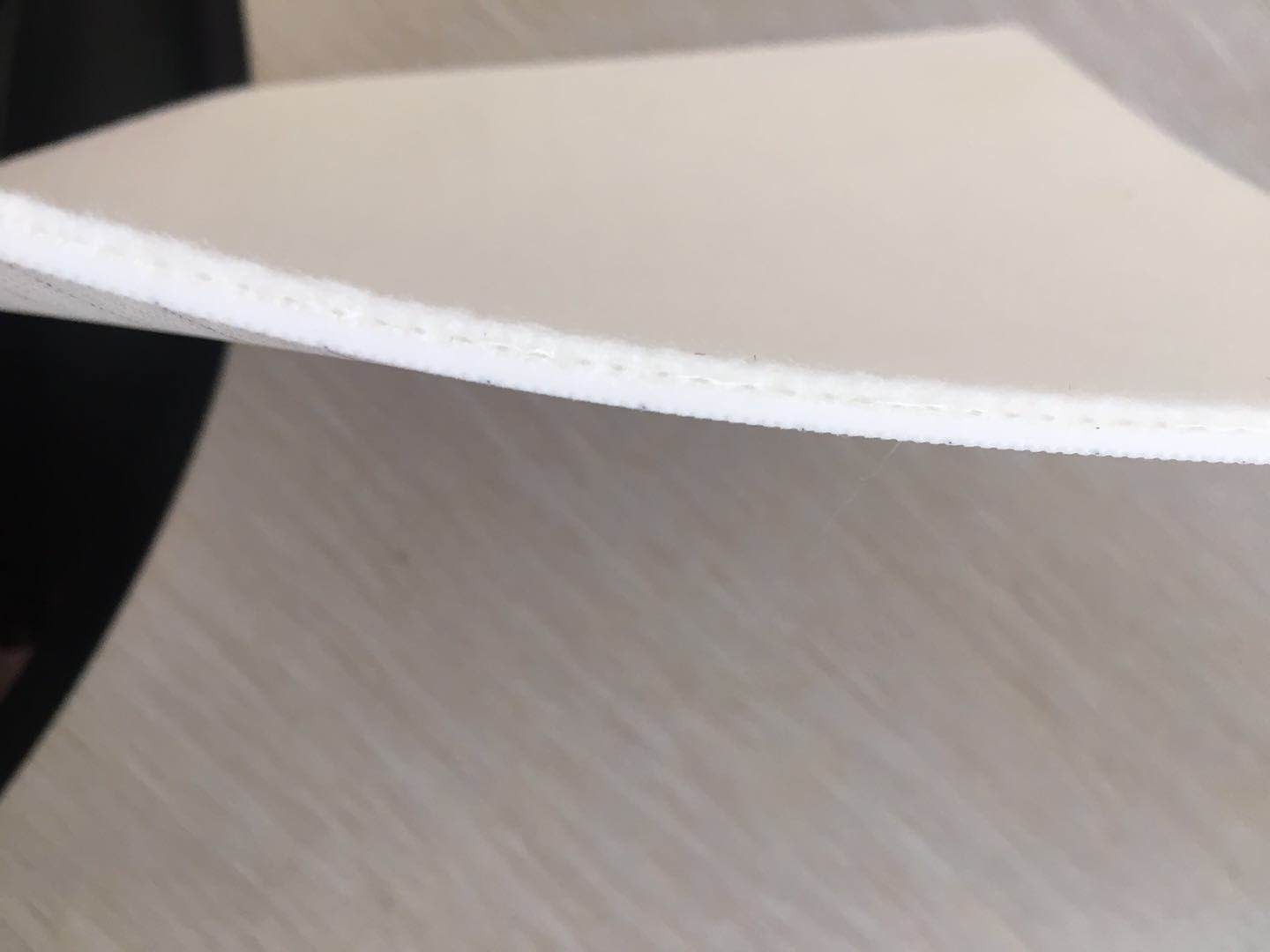

Overview of White PVC Conveyor Belts

Before delving into the importance of industry standards and certifications, it’s essential to understand what white PVC conveyor belts are and their broad range of applications. White PVC conveyor belts are made of polyvinyl chloride (PVC) material and are known for their excellent chemical resistance, mechanical strength, and suitability for food and pharmaceutical industries.

These conveyor belts are used in numerous industries, including food processing, agriculture, packaging, and manufacturing, where they facilitate the movement of products, materials, and components. Their versatility and durability make them a popular choice for various applications, but ensuring that you choose a reliable white PVC conveyor belt supplier is paramount.

The Significance of Quality and Reliability

Quality and reliability are paramount in material handling systems. A conveyor belt failure can lead to costly downtime, product damage, and, in some cases, safety hazards. To avoid these potential pitfalls, it is essential to source conveyor belts from suppliers who prioritize quality and reliability.

Industry Standards for White PVC Conveyor Belts

Industry standards play a crucial role in ensuring that products meet specific quality and performance criteria. For white PVC conveyor belts, there are well-established industry standards that suppliers should adhere to. These standards cover various aspects, including material composition, belt dimensions, and performance characteristics.

- Explanation of Industry Standards

Industry standards are established guidelines and specifications that products or services must meet to ensure quality, safety, and reliability. These standards are developed by industry associations, regulatory bodies, or international organizations, and they provide a benchmark against which products can be evaluated.

For white PVC conveyor belts, industry standards are in place to define the materials used, the construction of the belts, and the performance requirements they should meet. These standards serve as a common language that both suppliers and customers can understand and use for quality assurance.

- Specific Standards Relevant to White PVC Conveyor Belts

There are several specific industry standards relevant to white PVC conveyor belts, including:

ISO 21183: This international standard specifies the requirements for rubber and/or plastics-covered conveyor belting of textile construction for general use.

FDA Standards: For conveyor belts used in the food and pharmaceutical industries, compliance with Food and Drug Administration (FDA) regulations is essential. Suppliers should ensure that their white PVC conveyor belts meet FDA standards for food safety.

REACH Regulations: The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulations are particularly relevant for conveyor belts used in Europe. These regulations aim to ensure the safe use of chemicals in products.

These standards are just a few examples, and the choice of standards may depend on your specific industry and application. It’s essential to work with a white PVC conveyor belt supplier who understands the relevant standards and can provide documentation to demonstrate compliance.

- Their Purpose in Ensuring Quality and Reliability

Industry standards serve several important purposes in ensuring quality and reliability:

Consistency: Standards create a consistent baseline for product quality, making it easier for customers to assess the performance and quality of different products.

Safety: Standards often include safety requirements, which are crucial when using conveyor belts in industrial settings.

Reliability: By adhering to standards, suppliers can build products that are more reliable, reducing the risk of failure and downtime for their customers.

Certifications for Conveyor Belt Suppliers

In addition to the standards that govern the product itself, certifications for conveyor belt suppliers also play a significant role in ensuring quality and reliability. These certifications are a testament to a supplier’s commitment to maintaining a high level of quality throughout their manufacturing processes.

- The Role of Certifications in white PVC conveyor belt supplier Evaluation

Certifications provide an extra layer of assurance when selecting a conveyor belt supplier. They demonstrate that a supplier’s processes, from production to quality control, meet specific criteria. Some common certifications that suppliers may hold include:

ISO 9001: This certification focuses on quality management systems, ensuring that a white PVC conveyor belt supplierhas robust processes in place for maintaining consistent quality.

ISO 14001: This certification relates to environmental management systems and signifies a supplier’s commitment to environmentally responsible practices.

ISO 45001: When a white PVC conveyor belt supplierholds this certification, it demonstrates their dedication to occupational health and safety.

HACCP (Hazard Analysis and Critical Control Points): Particularly important for suppliers serving the food industry, this certification indicates a commitment to food safety.

- Examples of Certifications Relevant to Conveyor Belt Suppliers

Certifications relevant to conveyor belt suppliers may include ISO 9001, ISO 14001, ISO 45001, and specific certifications related to product quality, such as CE marking for compliance with European regulations.

These certifications demonstrate a supplier’s commitment to quality, safety, and environmental responsibility, all of which are crucial for ensuring the reliability of their products.

- How Certifications Contribute to Product Quality and Reliability

Certifications contribute to product quality and reliability in the following ways:

Process Improvement: Certification requirements often drive suppliers to improve their manufacturing and quality control processes, resulting in better products.

Consistency: Certified suppliers are more likely to deliver consistent products that meet or exceed customer expectations.

Accountability: Certifications hold suppliers accountable for maintaining high standards, and they are subject to audits to ensure compliance.

Key Considerations When Choosing a Supplier

As you select a white PVC conveyor belt supplier, there are several key considerations to keep in mind:

- Compliance with Industry Standards and Certifications

Ensure that the white PVC conveyor belt supplier you choose complies with the relevant industry standards and holds certifications that indicate their commitment to quality, safety, and environmental responsibility.

- Customization and Application Expertise

Consider whether the white PVC conveyor belt supplier can customize conveyor belts to your specific needs. Suppliers with expertise in your industry and applications can provide valuable insights.

- Reputation and Track Record

Research the supplier’s reputation and track record. Customer reviews, references, and case studies can provide valuable insights into their performance.

- Lead Time and Order Flexibility

Understand the supplier’s lead time for orders and whether they can accommodate expedited or bulk orders to align with your production schedule.

- Support and Troubleshooting

Inquire about the supplier’s after-sales support and their willingness to assist with troubleshooting common conveyor belt issues.

Potential Challenges and Pitfalls

While industry standards and certifications are valuable, there are some potential challenges and pitfalls to be aware of:

- Misinterpretation: Misinterpreting or misunderstanding standards and certifications can lead to misinformed decisions when choosing a supplier.

- Overlooking Customization: Focusing solely on standards and certifications may lead to overlooking the supplier’s ability to customize conveyor belts to specific needs.

- Assuming All Certifications Are Equal: Not all certifications hold the same weight, and the relevance of a certification may vary depending on the industry and application.

Conclusion

The choice of a white PVC conveyor belt supplier is a critical decision that can significantly impact the performance and reliability of your material handling systems. Industry standards and certifications provide a robust framework for evaluating and ensuring the quality and reliability of conveyor belts.

By understanding the role of industry standards, relevant certifications, and key considerations when choosing a supplier, you can make an informed decision that leads to a more efficient and dependable material handling process. Remember that white PVC conveyor belt supplier selection is not only about the product but also the long-term partnership and support they can offer. Choose wisely, and your investment in quality will pay dividends in terms of improved productivity and peace of mind.